Cochineal

COCHINEAL

For brilliant shades of fast red

Cochineal grains are scale insects that have been harvested from the pads of the prickly pear cactus. Female cochineal insects produce a red pigment inside their bodies called carminic acid which is one of the most brilliant and lightfast of the natural dyes. Carminic acid can produce vivid shades of crimson and scarlet, as well as fuchsias, lavenders, and royal purples, depending on the mordant it is paired with. At Shepherd Textiles we work directly with a farm in the high deserts of Peru to import the finest quality of freshly harvested and dried cochineal. Use at 1% for pinks, or 5-10% for rich reds on fibers mordanted with alum or tin.

1. Background on Cochineal

The cochineal or grana is a scale insect (dactylopius coccus) that lives out its life on cactus pads. The female produces a bright red substance called carminic acid to discourage predation. Carminic acid also happens to be an excellent textile dye that produces color-fast, light-fast reds and purples. The cultivation of cochineal for this purpose dates to the pre-Hispanic era in Mexico. In Nahua the insect was called nocheztli, which means blood-of-the-cactus (see Bassett and Peterson 2012:48). It was a common tribute item sent by the rural provinces to the capital, and Europeans first encountered it in the 16th century in the grand markets of Tenochtitlan.

Cochineal, along with silver and logwood, quickly became one of the most lucrative exports of New Spain. Cochineal displaced all the older red dyes in Europe, especially after it was discovered that it gives true scarlet with a tin mordant (Donkin 1977:6-11). Cochineal is brighter than kermes and lac, and much less finicky to work with than raw madder root. The Spanish prohibited export of the live insects and maintained a monopoly on cochineal until the beginning of the 19th century. After the Mexican Revolution a few bugs were smuggled out to Spain’s Canary Islands, but the industry there collapsed when synthetic red dyes were invented just a few decades later. However, cochineal extract, also known as carmine, is still an important commodity today because it remains the best source of natural red. It is widely used in the food industry to gives candies and soft drinks their signature red color.

2. Safety Precautions

DO NOT INGEST. Our cochineal is sold for textile dyeing, not as a food colorant.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spills. If a spill occurs, quickly wipe up with a paper towel or rag.

Cochineal can permanently dye clothing, countertops, rugs, utensils, or other property. Avoid contact with anything that is not meant to be dyed.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation..

Cochineal, metal mordants, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely. The best choice for cochineal is a stainless steel stock pot or a pot with a non-stick surface.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it is rinsed.

Candy thermometer. A cheap candy thermometer that clips to the side of the dye pot will make it easier to track the temperature.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Cream of tartar. Shifts color to red and improves dye uptake.

Tea bags or a coffee filter. For straining the dye bath.

Scale. Use a scale to weigh out fiber, mordant, and cochineal.

Respirator mask. If you plan to follow the historical recipe for True Scarlet, which uses oxalic acid, you will need to have a respirator mask to prevent breathing acidic fumes.

4. Mordanting

Cochineal is a substantive dye on animal fibers like wool and silk — meaning that it can be used without a mordant — but the best colors are always obtained in combination with mordants like alum and tin. Plant fibers in particular will require fairly aggressive mordanting with a metal salt before they can be dyed with cochineal. Different fibers require different mordanting procedures, which are outlined below. For the best results the fibers should be well-scoured and completely wetted through before mordanting, so that the mordant will penetrate them deeply and evenly. Make sure to weigh the fibers before beginning, while they are still dry, so that you can calculate weight-of-fabric (WOF) percentages. Note that some recipes require different mordants or no mordant at all; be sure to read each the recipe before mordanting.

To Mordant Woolen Fibers with Alum

Use 5% WOF alum and 5.5% WOF cream of tartar.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.05 to get the amount of alum you will need, and 0.055 to get the correct quantity of cream of tartar.

Scour (clean) the fibers well. We use liquid Synthrapol soap, but other scouring agents and detergents can be used. To scour with Synthapol, fill a dye pot with warm water, add 1 teaspoon Synthrapol per pound of wool, add the wool, and gently raise the heat to 160°F. Maintain this heat for one hour, stirring occasionally. After an hour, gently lift out the wool and transfer to a hot water bath and work it very gently to rinse it; repeat with fresh hot water baths until all dirt and suds have been rinsed away. Avoid transferring wool from a hot bath to a cold one, as the temperature shock can cause the wool to felt. When the wool is clean, proceed directly to mordanting.

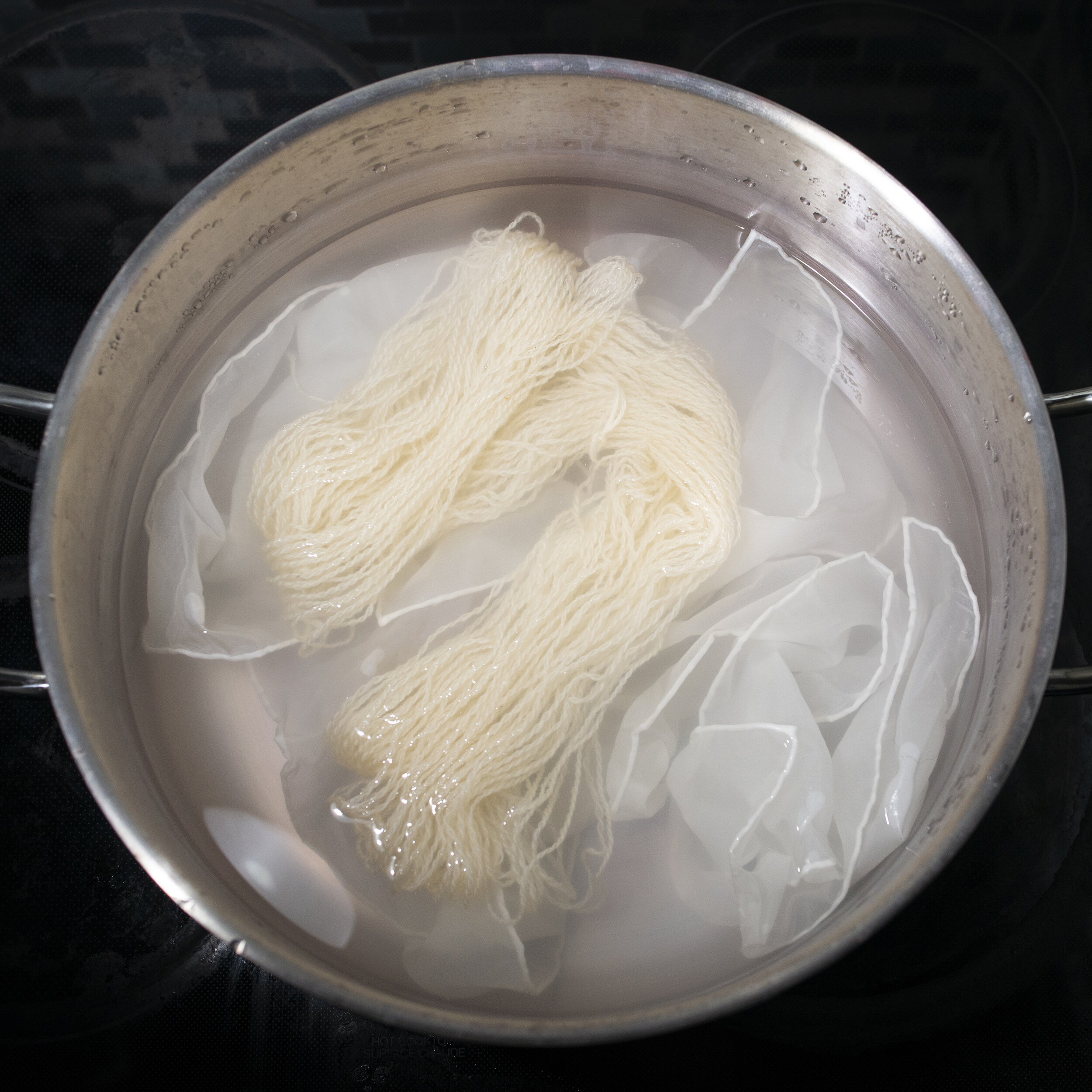

Fill a dye pot with enough warm water for the fibers to move around freely.

Weigh out the correct amount of cream of tartar and add to the dye pot. Mix well until dissolved.

Weigh out the correct amount of alum and add to the dye pot. Mix well until dissolved.

Gently place your scoured, wetted fibers into the mordanting solution.

[Optional] If you are dyeing very densely woven fabric, or tightly spun yarn, let the woolen fibers steep in the mordant bath for an hour before turning on the heat. This will give the mordant solution time to penetrate the fibers deeply and evenly.

Turn on the heat and gradually heat the mordant bath to 180°F. Cover the pot and maintain this heat for 1 hour.

Stir every 15 or 20 minutes to make sure the fibers mordant evenly. Otherwise, the resulting dye job may be uneven.

After an hour, remove from heat and let cool until safe enough to handle.

Remove cooled fibers and rinse well in lukewarm water. The fibers should not be washed with detergent, but should be rinsed well enough to remove any unbonded mordant and any excess acid from the mordant and cream of tartar.

Dispose of mordant solution according to local guidelines, and proceed to dyeing.

To Mordant Plant Fibers (Cotton and Linen) with Alum:

Treat with 10% WOF tannin and then 10% Aluminum Lactate

Cellulose fibers like cotton have much less attraction to metal mordants than woolen fibers do, so they require a different mordanting technique. There are two main methods of mordanting cotton with aluminum. The first is to saturate the cotton with a tannin like Sumac Extract, and then to mordant it; the tannin will combine with aluminum to precipitate the mordant onto the fiber. The second method is to saturate the cotton fibers in a very strong solution of a basic aluminum salt such as Aluminum Lactate (say, about 100 grams per liter of water), and then to precipitate the mordant directly onto the fiber. Both methods can be effective when dyeing with cochineal, but it is the first method we describe here.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.1 to get the amount of tannin and 0.1 to get the amount of aluminum lactate you will need.

Scour the fibers well. Fill a dye pot with hot water and add 1 gram of soda ash (sodium carbonate) and 1 drop of dish soap per pound of cotton or linen. Add fibers and bring just to a boil, then lower the heat to 200°F for one hour, stirring occasionally. After an hour, remove from heat. When cool enough to safely handle, rinse well and gently wring out. Proceed to tanning.

Fill a dye pot with enough lukewarm water for your fibers to move around freely.

Weigh out the correct amount of Sumac Extract and add to the dye pot. Mix well until dissolved.

Gently place the scoured cotton or linen into the tannin bath. Gradually bring the bath just to a boil, then reduce the heat to a gentle simmer (around 200°F). Maintain this temperature for 30 minutes, stirring regularly so the fiber tans evenly.

After 30 minutes, remove the pot from heat, cover, and allow to cool down completely. The cotton fibers will absorb a significant amount of tannin during this cooling-down phase. Steep until completely cool, or (if they cool down very quickly) for a minimum of 3 hours. Stir regularly.

[Optional] For the darkest results, let the cotton steep in the tannin bath overnight. This will give the darkest colors, but the trade-off is that it may result in some unevenness, especially if any bubbles are trapped under the fiber or if some of the fiber is not completely submerged.

When ready to proceed, remove the cotton fibers from the tannin bath. Gently wring them out, but do not rinse them; rinsing them will wash out some of the tannins and result in paler colors later on. Set aside.

Prepare a mordant bath with aluminum lactate. Fill a dye pot with enough warm water for your fibers to move around freely. Measure out the correct amount of aluminum lactate, add it to the pot, and stir well until dissolved.

Heat the aluminum lactate mordant bath until it is hot but not boiling, around 150°F or 160°F. Gently add the tanned cotton fibers. Adding them when the mordant bath is already hot will make sure the tannins quickly bond to the cotton fibers, and do not wash out into the mordant bath.

Heat the mordant bath to 200°F and maintain for 30 minutes. After 30 minutes, turn off the heat and allow to cool

Once cool enough to handle safely, remove the cotton fibers from the mordant bath and rinse very well in several changes of hot water. Proceed directly to dyeing.

Recipes

5. Crimson on Woolens

Historically, cochineal was used to produce two distinct shades of red: crimson and scarlet. Crimson is the cooler shade of red that develops when cochineal is combined with an aluminum mordant. Cochineal crimson has good fastness to light, to washing, and to rubbing, and some professional dyers considered it superior even to synthetic red dyes. This is the probably the most common method of dyeing with cochineal today and it tends to give excellent results on woolen fibers of all kinds.

Wool Yarn, 1% WOF

Wool Yarn, 5% WOF

Wool Yarn, 10% WOF

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of cochineal. Use 1% for pink, 5% for a medium crimson, or 10% for a dark crimson.

Add the cochineal to the dye bath and extract the color by boiling it. Whole cochineal grains will need to be boiled for about 2 hours to extract the color. Ground or roughly crushed cochineal only needs to be boiled for about half an hour. After extracting the color, strain or filter out the spent cochineal. Alternatively, put ground cochineal in a tea bag or muslin bag before boiling it; the bag can easily be removed and discarded after all the color has been extracted.

[Optional] Acidify the dye bath by adding 1 gram of cream of tartar per gallon of water in the dye bath. This will shift the final color toward a warmer shade of crimson (note that the swatches above were dyed without adding the optional cream of tartar, resulting in a cooler shade of crimson).

Allow the dye bath to cool down before adding the fibers; adding them while the bath is still hot may result in an uneven dye job. You can add a little cold water to speed up this process.

When the dye bath is cool, gently add your wetted, alum-mordanted woolen fibers.

Heat the dyebath to 200°F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol)[see note]. Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*NOTE: Cochineal crimson is pH-sensitive, and strong alkalis like washing soda can shift the color of the dyed fibers toward the purplish end of the red spectrum. Many household laundry detergents are strongly alkaline, so they should be avoided if you want to maintain the same hue of red.

6. Fuchsia on Cotton

The carminic acid in cochineal will not dye plant fibers like cotton and linen unless they have previously been mordanted, successful dyeing will depend almost entirely on how well the fibers were mordanted. Cotton also needs to be dyed in a neutral or very slightly alkaline bath — adding cream of tartar is counterproductive (it prevents the dye from bonding to the cotton) and anyways it will not shift the color toward warmer shades of red. When dyed on well-mordanted cotton or linen, however, cochineal can produce some good shades of pink or fuchsia that are otherwise difficult to obtain on plant fibers.

Cotton Shirt, 1% WOF

Cotton Shirt, 3% WOF

Cotton Shirt, 6% WOF

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of cochineal. Use 1% for a pale pink, 3% for a light fuchsia, or 6% for a medium fuchsia.

Add the cochineal to the dye bath and extract the color by boiling it. Whole cochineal grains will need to be boiled for about 2 hours to extract the color. Ground or roughly crushed cochineal only needs to be boiled for about half an hour. After extracting the color, strain or filter out the spent cochineal. Alternatively, put ground cochineal in a tea bag or muslin bag before boiling it; the bag can easily be removed and discarded after all the color has been extracted.

Allow the dye bath to cool down before adding the fibers; adding them while the bath is still hot may result in an uneven dye job. You can add a little cold water to speed up this process.

When the dye bath is cool, gently add your wetted, alum-mordanted cotton fibers.

Heat the dyebath to 200°F very gradually, over the course of about 30 minutes, stirring regularly so that the cotton dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the cotton is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of cotton (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

7. Simple Scarlet on Woolens

When combined with a tin mordant, cochineal will produce intense shades of scarlet red. Scarlet is a warmer, yellower shade of red than crimson. The most brilliant scarlets are obtained by combining cochineal, tin, and oxalic acid in a single bath, but oxalic acid is a hazardous chemical and something that many natural dyers may want to avoid working with. Fortunately, good scarlets can also be obtained without needing to use oxalic acid, by pre-mordanting wool with tin and cream of tartar.

Wool Yarn, 5% WOF

Wool Yarn, 10% WOF

Wool Yarn, 15% WOF

Prepare by mordanting the woolen fibers with tin instead of alum. Follow the directions in Section 4, but use 5% tin and 5% cream of tartar. The mordanting process is otherwise the same, although additional safety precautions should be observed when working with tin mordant [see Note 1].

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of cochineal. Use 5% for a light scarlet, 10% for a medium scarlet, or 15% for a dark scarlet.

Add the cochineal to the dye bath and extract the color by boiling it. Whole cochineal grains will need to be boiled for about 2 hours to extract the color. Ground or roughly crushed cochineal only needs to be boiled for about half an hour. After extracting the color, strain or filter out the spent cochineal. Alternatively, put ground cochineal in a tea bag or muslin bag before boiling it; the bag can easily be removed and discarded after all the color has been extracted.

Allow the dye bath to cool down before adding the fibers; adding them while the bath is still hot may result in an uneven dye job. If there is room in the dye pot, you can add a little cold water to speed up this process.

When the dye bath is cool, gently add your wetted, tin-mordanted woolen fibers.

Allow the fibers to steep in the dye bath for 30 minutes before turning on the heat, stirring them occasionally. Cochineal will bond to the tin-mordanted fibers very quickly once the heat is turned on, so this extra 30 minutes without heat gives the dye bath time to penetrate the fibers fully and evenly.

Heat the dyebath to 200°F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol)[see note]. Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*NOTE 1: CAUTION: Tin mordant (stannous chloride powder) is corrosive and it should be handled with care. The powder can cause extreme burns if it comes into contact with the eyes or mucus membranes. Wear gloves, a mask, and eye protection when handling tin mordant and tin mordant baths. Avoid inhaling powder dust or breathing fumes from the mordant bath. Be sure to read your vendor’s SDS (Safety Data Sheet) before using tin mordant, and observe all recommended safety precautions. Keep tin mordant and tin mordant baths out of reach of children.

8. True Scarlet on Woolens

When combined in a single bath with tin and oxalic acid, cochineal produces a deep and intense shade of scarlet that was considered by many professionals to be one of the finest colors ever achieved by the craft of dyeing. This is the scarlet that for centuries was employed for the clothing of nobles, military officers, and royals. Although it is very beautiful, it requires two relatively hazardous chemicals — tin and oxalic acid — so it should only be attempted by dyers who have an outdoor dyeing setup (to dissipate fumes) and full protective gear. Be sure to read the safety notes below before beginning.

Wool Yarn, 5% WOF

Wool Yarn, 10% WOF

Wool Yarn, 15% WOF

Prepare your woolen fibers by scouring them very well, but do not mordant them. They should be clean and thoroughly wetted before beginning.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of cochineal. Use 5% for a light scarlet, 10% for a medium scarlet, or 15% for a dark scarlet.

Add the cochineal to the dye bath and extract the color by boiling it. Whole cochineal grains will need to be boiled for about 2 hours to extract the color. Ground or roughly crushed cochineal only needs to be boiled for about half an hour. After extracting the color, strain or filter out the spent cochineal. Alternatively, put ground cochineal in a tea bag or muslin bag before boiling it; the bag can easily be removed and discarded after all the color has been extracted.

After the cochineal has been strained or filtered out, allow the dye bath to cool down to room temperature before proceeding. If there is room in the dye pot, you can add a little cold water to speed up this process.

Weigh out 6% weight-of-fabric (WOF) of oxalic acid* [see Note 1]. Add to the dye bath and mix until fully dissolved.

Weigh out 5% weight-of-fabric (WOF) of tin mordant (stannous chloride)* [see Note 2]. Add to the the dye bath and mix well until dissolved.

Gently place your scoured (but unmordanted) woolen fibers into the dye bath.

Let the wool fibers steep in the dye bath for 30 minutes before turning on the heat. Stir the fibers a few times while waiting. This will help the dye and mordant to penetrate the fibers fully and evenly before heat causes them to start to bond with each other.

Turn on the heat and heat the dyebath to a boil very gradually, over the course of at least 30 minutes, stirring regularly so that the wool dyes evenly. When the dye bath just reaches a boil, immediately lower the heat, cover the pot, and maintain the temperature at around 200°F for one and a half hours. Uncover and stir the fibers occasionally so they dye evenly; avoid inhaling fumes. After 1 and a half hours, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*Note 1: CAUTION: Oxalic acid is one of the strongest organic acids, and it is required in this recipe in order to keep the large quantities of tin and carminic acid from bonding to each other prematurely and forming little particles of pigment. Oxalic acid can cause serious burns if it touches the eyes, skin, or mucous membranes, and oxalic acid fumes should not be inhaled. Only attempt this recipe if you have an outdoor dyeing setup and full protective gear (gloves, goggles, and respirator mask). Read your manufacturer’s SDS before beginning and observe all recommended safety protocols. If you follow this recipe you agree that Shepherd Textiles LLC is not responsible for any adverse consequences of dyeing with oxalic acid or stannous chloride.

*Note 2: CAUTION: Tin mordant (stannous chloride powder) is corrosive and it should be handled with care. The powder can cause extreme burns if it comes into contact with the eyes or mucus membranes. Wear gloves, a mask, and eye protection when handling tin mordant and tin mordant baths. Avoid inhaling powder dust or breathing fumes from the mordant bath. Be sure to read your vendor’s SDS (Safety Data Sheet) before using tin mordant, and observe all recommended safety precautions. Keep tin mordant and tin mordant baths out of reach of children.

9. Natural Lilac on Woolens

Cochineal is substantive on animal fibers, which is to say that it will dye them without the need for a mordant. Technically when it is used in this way cochineal is acting as a stain rather than as a true dye (since there is no color lake or compound being formed on the fiber), but it works fairly well on wool nonetheless and has good fastness to washing and rubbing. The color without a mordant tends toward a warm purple or lilac, but it is sensitive to pH and the final color may vary depending on the acidity and hardness of the water in the dye bath.

Wool Yarn, 1% WOF

Wool Yarn, 5% WOF

Wool Yarn, 10% WOF

Prepare the fibers by scouring them very well, but do not mordant them. They should be clean and thoroughly wetted before beginning.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of cochineal. Use 1% for a pale lavender, 5% for a medium lilac, or 10% for a dark lilac.

Add the cochineal to the dye bath and extract the color by boiling it. Whole cochineal grains will need to be boiled for about 2 hours to extract the color. Ground or roughly crushed cochineal only needs to be boiled for about half an hour. After extracting the color, strain or filter out the spent cochineal. Alternatively, put ground cochineal in a tea bag or muslin bag before boiling it; the bag can easily be removed and discarded after all the color has been extracted.

After extracting the color and filtering out the cochineal, add 1 gram of cream of tartar per gallon of water in the dye bath. The cream of tartar will help the fibers absorb the color more readily.

Allow the dye bath to cool down before adding the fibers; adding them while the bath is still hot may result in an uneven dye job. If there is room in the dye pot, you can add a little cold water to speed up this process.

When the dye bath is cool, gently add your wetted, unmordanted woolen fibers.

Heat the dyebath to 200°F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol)[see note]. Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

10. Purple on Woolens

Like many other natural red dyes, cochineal will shift to purple when used with an iron mordant. Iron has developed an undeserved reputation among some dyers as a poor choice for mordanting wool, because when used incorrectly it can be harsh on woolen fibers. The key to successfully mordanting wool with iron is to use plenty of cream of tartar — as much as 20% of the weight of the fiber itself — which prevents the iron from turning the wool brown or making it feel coarse.

Wool Yarn, 1% WOF

Wool Yarn, 5% WOF

Wool Yarn, 10% WOF

Prepare by mordanting the woolen fibers with iron instead of alum. Follow the directions in Section 4, but use 8% iron and 20% cream of tartar. The mordanting process is otherwise the same, although additional safety precautions should be observed when working with iron mordant [see Note*].

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of cochineal. Use 1% for a pastel purple, 5% for a medium purple, or 10% for a dark purple.

Add the cochineal to the dye bath and extract the color by boiling it. Whole cochineal grains will need to be boiled for about 2 hours to extract the color. Ground or roughly crushed cochineal only needs to be boiled for about half an hour. After extracting the color, strain or filter out the spent cochineal. Alternatively, put ground cochineal in a tea bag or muslin bag before boiling it; the bag can easily be removed and discarded after all the color has been extracted.

Allow the dye bath to cool down before adding the fibers; adding them while the bath is still hot may result in an uneven dye job. You can add a little cold water to speed up this process.

When the dye bath is cool, gently add your wetted, alum-mordanted woolen fibers.

Heat the dyebath to 200°F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol)[see note]. Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*NOTE: Iron mordant (ferrous sulfate) is hazardous if ingested, especially in the quantities used in mordanting. Store iron powder and iron mordant baths out of reach of children. In case of accidental ingestion, seek immediate medical attention. Read your vendor’s SDS (Safety Data Sheet) before using ferrous sulfate and observe all recommended safety precautions.

11. Plant-Mordanted Red on Woolens

Cochineal works particularly well on wool with Nature’s Mordant, our 100% plant-based mordant for natural dyes. The combination produces good shades of pink and crimson on woolen fibers (in contrast to the lilac shades that develop when no mordant at all is used). Nature’s Mordant is a natural and sustainable alternative to industrial metal salts like stannous chloride and aluminum sulfate, and it makes it possible to dye cochineal without needing to use any synthetic chemicals.

Wool Yarn, 1% WOF

Wool Yarn, 4% WOF

Prepare by mordanting the woolen fibers with Nature’s Mordant™ instead of alum. Follow the directions on the Nature’s Mordant page [here], using 4% Nature’s Mordant™ and 2% cream of tartar.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of cochineal. Use 1% for pink, or 4% for a light crimson.

Add the cochineal to the dye bath and extract the color by boiling it. Whole cochineal grains will need to be boiled for about 2 hours to extract the color. Ground or roughly crushed cochineal only needs to be boiled for about half an hour. After extracting the color, strain or filter out the spent cochineal. Alternatively, put ground cochineal in a tea bag or muslin bag before boiling it; the bag can easily be removed and discarded after all the color has been extracted.

After filtering or straining out the cochineal, add 2 grams of cream of tartar per gallon of water in the dye bath. The acid in the cream of tartar will help the wool to absorb the dye.

Allow the dye bath to cool down before adding the fibers; adding them while the bath is still hot may result in an uneven dye job. You can add a little cold water to speed up this process.

When the dye bath is cool, gently add your wetted, alum-mordanted woolen fibers.

Heat the dyebath to 200°F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol)[see note]. Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*All text and images are copyright of Shepherd Textiles, LLC. Do not reproduce without permission and attribution.