Camwood

A Guide to Camwood

Shepherd Textiles Camwood Natural Dye is made from the heartwood of baphia nitida, a small evergreen tree native to West Africa. Camwood was known to dyers as one of the three “insoluble reds” along with Barwood and Red Sandalwood, and it was actually one of the most important dyes of the 18th and 19th centuries. Camwood was exported to Europe and the United States in immense quantities to dye reds and pinks as well as compound colors like brown and black. However, it fell into obscurity after the invention of synthetic aniline dyes. On alum Camwood gives rusty reds; tin gives pinks and crimsons; and iron deep eggplant purples. Camwood produces soft shades at 30% weight-of-fabric and strong shades at 100% using the traditional “stuffing and saddening” method described below. Product of Nigeria.

1. Background on Camwood

Camwood, baphia nitida, is an evergreen tree native to a small stretch of the West African coast between Sierra Leone and Cameroon. The heartwood of the tree is a deep red color, and it contains a set of pigments called santarubins that are similar to those found in two other important dye woods, Red Sandalwood (pterocarpus santalinus) and Barwood (pterocarpus soyauxxi). Together, those three were known to Victorian dyers as the “insoluble reds” because the santarubin pigments they contain are only sparingly soluble in water. Camwood was said to give bluer shades of red than the other two, whereas Red Sandalwood gives reds with the most orange in them (Hummel 1885:343). Camwood was one of the most important dyestuffs of the 18th and 19th centuries. It was exported in vast quantities to Europe for dyeing reds and pinks, and it was also an ingredient in countless recipes for compound colors like brown and black. However, it fell into obscurity with the advent of synthetic aniline dyes at the end of the 19th century and was mostly forgotten.

Historically, there was an enormous amount of confusion regarding the botanical identities of Camwood (baphia nitida) and Barwood (pterocarpus soyauxxi). This was partly a product of nomenclature; both are referred to casually as “red sandalwood” or “African red sandalwood,” leading to occasional misidentifications. It was also a product of geography; Camwood and Barwood have overlapping ranges in West Africa and both woods were shipped out of the same ports, so by the time dyers in Europe got hold of the timbers they were not always certain which species they were getting. Camwood was (and still is) rarer and more expensive than Barwood, so merchants also had a motive to misidentify their wares. As a result, there are some conflicting accounts in the historical literature regarding the botanical identities and relative potencies of the two species (see, e.g., Knecht 1910:360) but most dyers agreed that they could be distinguished because Camwood gives bluer shades than the other two insoluble reds.

Our Camwood (baphia nitida) is sourced from Nigeria, where it is still harvested today as a traditional medicine and skin tonic. It can be applied either by extracting the pigments with alcohol, or using the traditional “stuffing and saddening” method described in the recipes below. It gives strong shades at 100% weight-of-fabric, including a beautiful pink-crimson with a tin mordant or a rich aubergine purple with iron. This is a diverse and historically significant dyestuff that many dyers will enjoy experimenting with.

The Bluest of the “Insoluble Reds”

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust. Avoid inhaling wood dust.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Camwood, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Prop 65 Warning: This product contains wood dust, which is known to the State of California to cause cancer.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

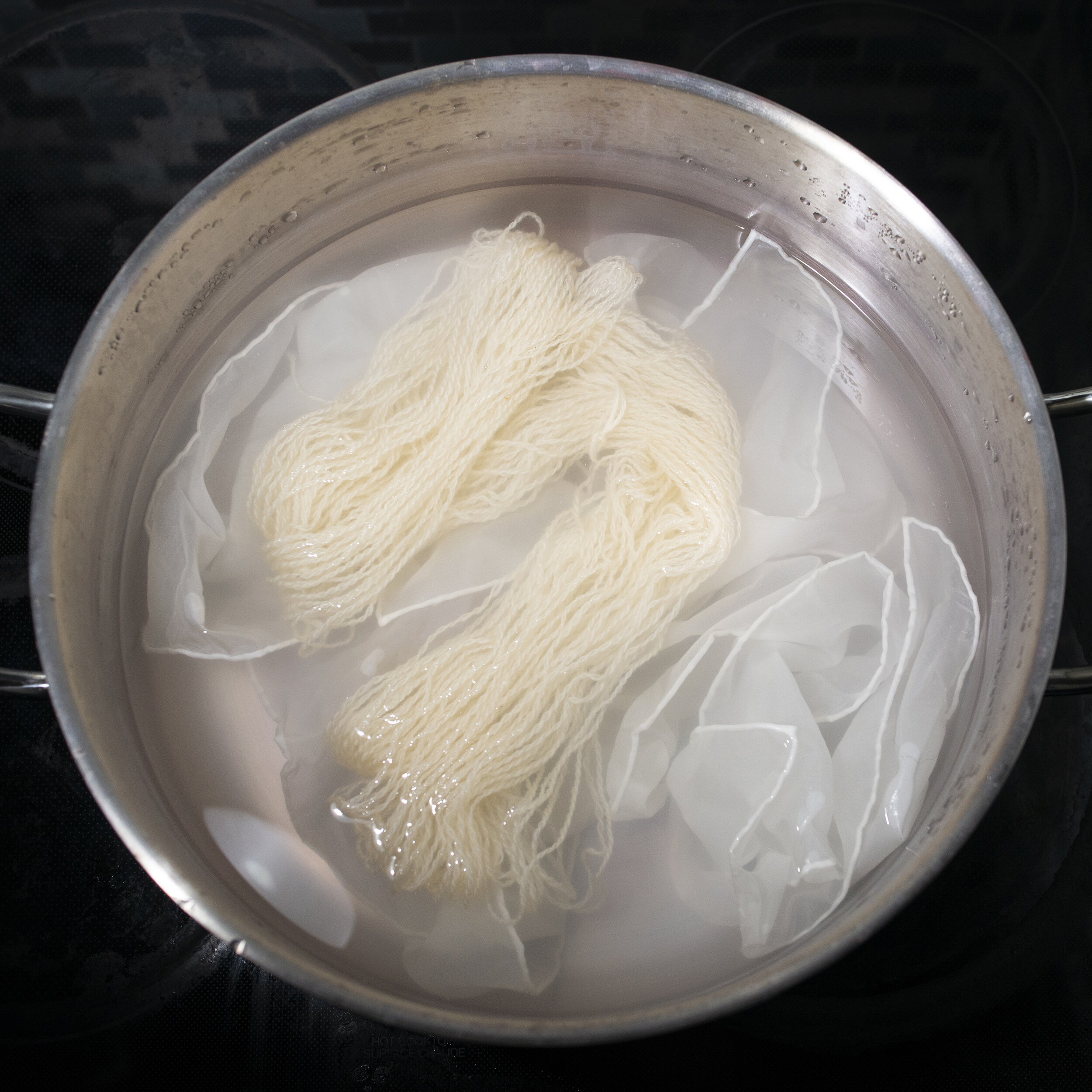

4. Preparation: Scouring and (Maybe) Mordanting

Historically, Camwood was applied by the “stuffing and saddening” or post-mordanting method. This method is necessary because the santarubin pigments in Camwood are almost entirely insoluble in water. They have to be very slowly simmered out of the wood and “stuffed” into the fibers so that the fibers (and the concentrated dye they contain after a few hours of stuffing) can all be mordanted together. In this case, premordanting is unnecessary. However, when dyeing with an alcoholic tincture of Camwood, the fibers are still premordanted as usual. In each case, the fibers should be well scoured (cleaned).

For wool fibers (wool, alpaca, etc.): Mordant with 10% alum and 11% cream of tartar.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.10 to calculate the amount of alum you will need, and 0.11 to calculate the amount of cream of tartar.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of cream of tartar and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Next, weight out the correct amount of alum and add it to the dye pot. Mix until well dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180°F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180°F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. Otherwise, an uneven dye job may result.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results when dyeing thick yarn or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers well in lukewarm water. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For silk: Mordant with 15% alum.

Follow the directions for mordanting wool described above. However, use 15% alum and omit the cream of tartar.

For cellulose fibers (cotton, linen, etc.): Treat with a tannin before mordanting.

Scour (clean) the cotton by adding 1 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with just enough hot water for your fibers to move around freely - the more concentrated the tannin bath, the stronger the results will be. Dissolve 20% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they can bond to the mordant. For the very strongest results, hang the cotton up and let it dry before proceeding to mordanting.

Prepare an alum mordant bath using either (a) 20% weight-of-fabric alum + 5% soda ash (washing soda), or (b) 20% weight-of-fabric of aluminum lactate. Either option will create a relatively neutral pH mordant bath that bonds well with cotton.

Heat the mordant bath to 150°F or 160°F, place the cotton in it, and raise the heat to 190°F. Maintain for one hour, stirring occcasionally to make sure the fibers mordant evenly. After one hour, remove from heat. When cool enough to handle safely, remove fibers and rinse well in lukewarm water.

The Recipes

5. Recipe: Coral

When Camwood is extracted with alcohol, it produces some clear and beautiful pink-orange shades. They will look much redder in the dyebath, but will shift toward orange after rinsing and drying. Considering the weight of wood and quantity of spirits required, this recipe is probably not very economical for large woolen projects. For smaller projects or lighter weights of silk, however, the results are worth the investment.

Preparation: Make a Camwood Tincture

Measure out 100% weight-of-fabric (WOF) of Camwood powder and place in a glass jar. Cover with 1.5 cups of clear spirits per ounce of Camwood powder. Mix well, cover, and let steep for 3 to 5 days. Use 50%-90% ABV spirits for the best results.

Dyeing Procedure

Fill your dye pot with enough warm water for your fibers to move around freely.

Strain the Camwood tincture into the dye bath. It should turn a deep ruby red color.

Add your alum-mordanted fiber to the dyebath.

Raise the temperature gradually to 180°F for silk or 190-200°F for wool and cotton, then maintain for 1 hour*. Stir occasionally to make sure everything dyes evenly.

After 1 hour, remove pot from heat and allow to cool until the fiber can safely be handled.

Remove the fibers and rinse briefly in warm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Canwood will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*Note: Camwood tincture can be very difficult to dye level (even). Some parts of the fiber will often turn out a little darker, some a little lighter. This tendency can be mitigated somewhat by raising the temperature of the dyebath very slowly, which helps the fibers dye more evenly.

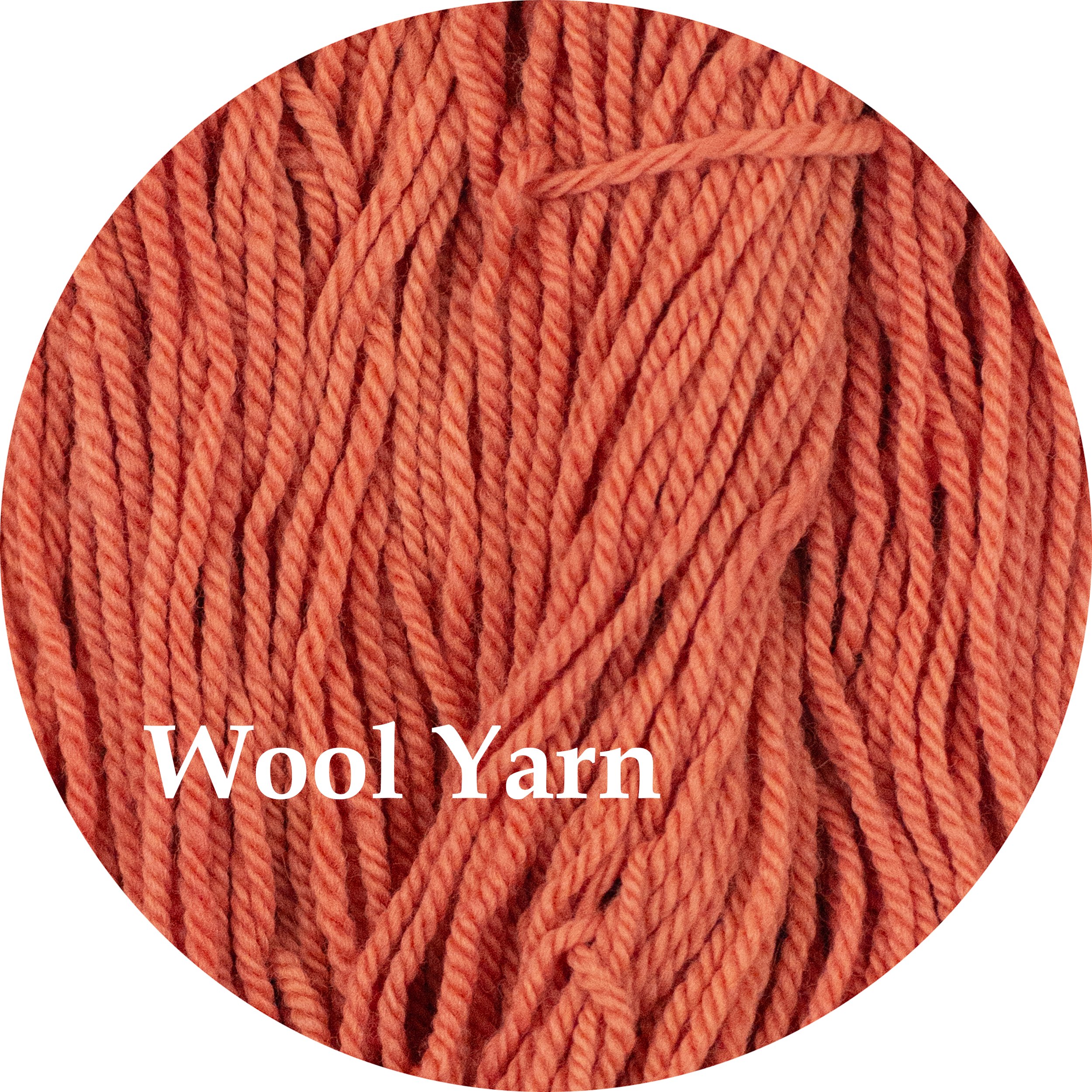

6. Recipe: Aubergine

Professional dyers in the 18th and 19th centuries applied Camwood via the “stuffing and saddening” method, which we refer to today as post-mordanting. Unmordanted wool is heated in the dye bath together with the wood powder: this causes the pigments to slowly dissolve out of the wood and soak into the wool fibers. After an hour and a half, the wool is lifted out and transferred into a mordant bath. Saddening with iron gives strong and attractive results: a deep eggplant purple at 100% WOF, or a purple-brown at 30%.

Fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 30% weight-of-fabric (WOF) of Camwood powder (for a lighter purple-brown) or 100% weight-of-fabric (for a dark aubergine shade). Place the wood powder into large tea bags, or muslin dye bags, and tie securely shut. [The wood must be in the dye bath together with the wool for this method to work: as the pigments soak into the wool fibers, their concentration in the water is reduced and more pigments can then dissolve out of the wood.]

Add your scoured but unmordanted wool to the dye bath.

Raise the heat to 200°F-205°F and maintain for 1.5 hours. [Camwood is one of the “Insoluble Reds” - the pigments it contains are insoluble in cold water and only barely soluble in boiling water. The dye bath must be kept as close to a boil (210°F) as possible, or the results will be very pale. For best results, let the bath just reach a boil at 210°F - a few bubbles will be coming up, but it will not be a full rolling boil*.]

After an hour and a half, prepare an iron saddening bath**: fill a dye pot with enough warm water for your fibers to move around freely. Add 5% WOF of iron powder and mix well until dissolved. Then, raise the temperature of the iron saddening bath to about 160°F.

When the saddening bath is ready, lift the wool out of the dye bath with tongs; let the excess liquid drain back into the dye pot for a minute or so, then gently place them in the saddening bath.

Raise the temperature of the saddening bath to 190°F and maintain for 20 minutes.

After 20 minutes, remove from the heat and let cool until the fibers can safely be removed with tongs.

Remove the fibers and rinse briefly in warm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Camwood may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*NOTE: Many of us have been taught that letting wool boil will ruin it, either by felting it or by making it feel coarse. However, merino yarn dyed by this method (kept at a steady 205°-210°F for an hour and a half) was not terribly harsher or felted. Just be careful not to let the bath come to a rolling boil.

**CAUTION: Ferrous sulfate (iron powder) is harmful if ingested. Keep iron and iron mordant baths away from children and pets. Avoid contact with skin and mucus membranes. Wear gloves and eye protection while handling iron powder and iron mordant baths. Dispose of the spent mordant bath according to local regulations. Read your manufacturer’s SDS (Safety Data Sheet) before working with ferrous sulfate and observe all recommended safety precautions.

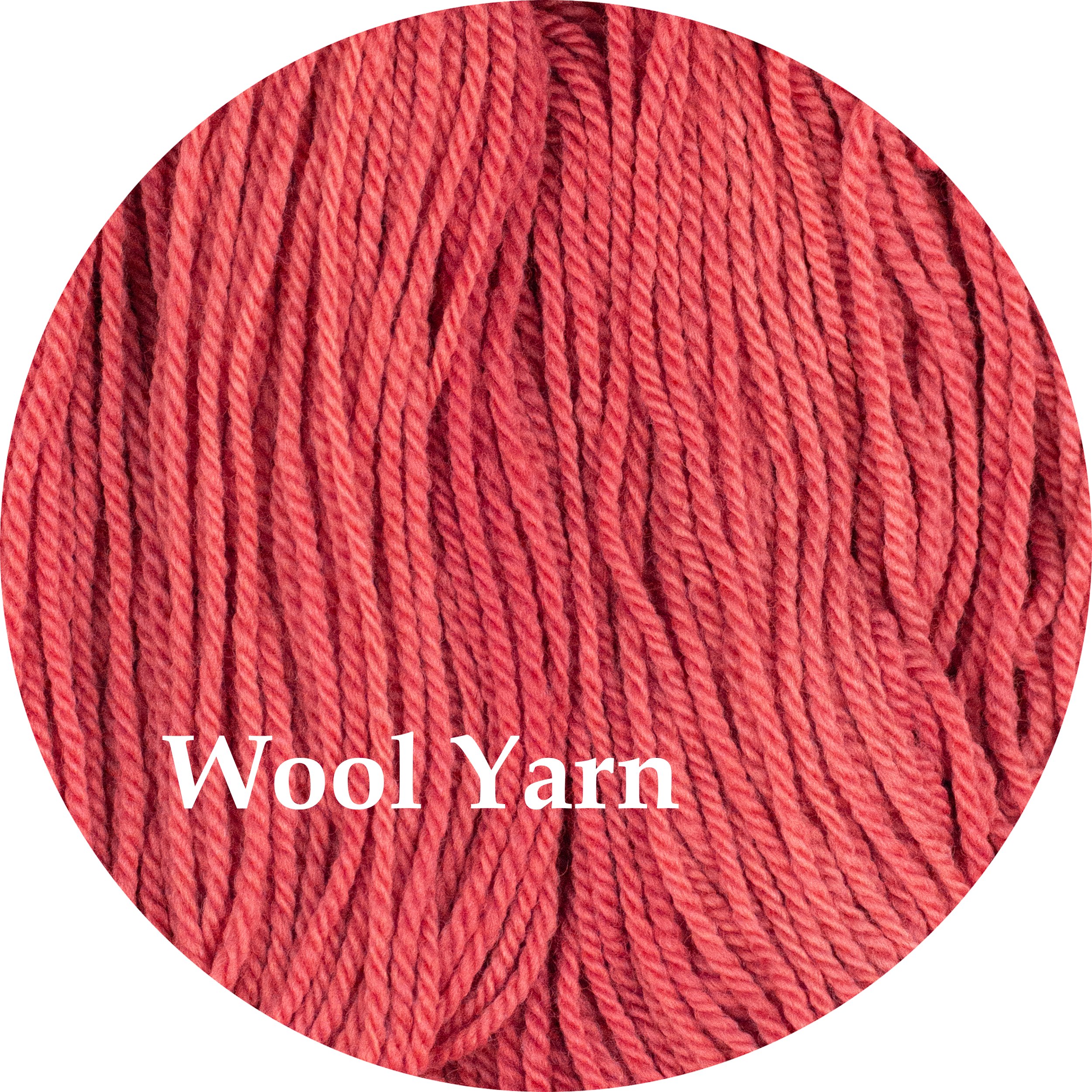

7. Recipe: Ruddy Pink

Saddening with a small amount of tin - just 1% weight-of-fabric - gives excellent results with Camwood. It emphasizes Camwood’s naturally bluer shade of red, and produces pleasant pink shades. With heavier concentrations of wood - about 100% WOF - the color becomes a deep ruddy pink.

Follow the directions for “Aubergine” described in Section 6. Use 30% weight-of-fabric of Camwood powder for a soft pink shade, or 100% for a dark ruddy pink. When you are ready to build the saddening bath (Step 5), use 1% tin instead of iron. Otherwise, proceed with the recipe.

8. Recipe: Drab Red

When saddened with alum, light concentrations of Camwood turn a very good pink shade, one that is more yellow than the blueish shade of pink produced with tin. At heavier concentrations the color shifts toward a reddish brown or drab.

Follow the directions for “Aubergine” described in Section 6. Use 30% weight-of-fabric of Camwood powder for a neutral pink shade, or 100% for a drab red. When you are ready to build the saddening bath (Step 5), use 10% alum instead of the iron. Otherwise, proceed with the recipe.

8. Recipe: Camwood on Cotton

Historically, insoluble reds like Camwood were used to dye cotton as well as wool. They produce pleasant pinks all the way to orange-reds on cotton pre-mordanted with alum. However, the challenge is still getting the insoluble pigments out of the wood and into the cotton. In the past, dyers would boil cotton together with loose wood powder, letting the wood touch the fiber directly to aid in the transfer of color. This produces deeper shades, but it can be difficult to wash out all the tiny specks of wood after dyeing.

Fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 100% weight-of-fabric (WOF) of Camwood powder. Do not put it into tea bags or muslin dye bags; put the powder directly into the dye bath**.

Add cotton fibers pre-mordanted with alum.

Raise the heat to a gentle boil at 210°F. Maintain for one hour. Move the fibers around frequently so that they dye evenly; wherever the wood powder settles on the fiber, the color will be darker.

After 1 hour, remove from the heat and let cool until the fibers can safely be removed with tongs.

Remove the fibers and rinse well in warm water. Try to get as much as the wood powder off as possible; some of it may come off more easily after the cotton has dried. Hang the fibers up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Camwood may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*NOTE: In regards to dyeing cotton with Camwood, Crookes (1874:342) says that “absolute contact between the ware and the mordanted goods appears necessary, and, unlike ordinary cotton-dyeing operations, it is carried on at a boiling heat. A reduction of temperature is fatal to good results.” The Camwood should be loose in the dyebath - in direct contact with the cotton - for the darkest colors. However, it can be very hard to rinse the wood powder out afterwards. You may want to run a test swatch first to see how hard it is to remove wood powder from your material. If you are content with more pale shades, it would probably be more convenient to put the wood in a tea bag or muslin bag, as when dyeing wool.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.