Cochineal Extract C.A. Plus™

A Guide to Cochineal C.A. Plus

Shepherd Textiles Cochineal C.A. Plus™ is a new form of Peruvian cochineal extract that is rich in highly soluble carminic acid. In contrast to carmine - the traditional form of cochineal extract that has been in use since the 17th century - Cochineal C.A. Plus is easier to dissolve, easier to apply to mordanted fiber, and yields results more similar to raw cochineal. This is a very potent extract that will yield bright cherry reds at just 2% weight-of-fabric on woollen fibers mordanted with alum. The hue can be modified by adjusting the pH of the dye bath, or the color can be shifted to a lilac purple by adding iron. Product of Peru.

1. Background on Cochineal

The cochineal or grana is a scale insect (dactylopius coccus) that lives out its life on cactus pads. The female produces a bright red substance called carminic acid to discourage predation. Carminic acid also happens to be an excellent textile dye that produces color-fast, light-fast reds and purples. The cultivation of cochineal for this purpose dates to the pre-Hispanic era in Mexico. In Nahua the insect was called nocheztli, which means blood-of-the-cactus (see Bassett and Peterson 2012:48). It was a common tribute item sent by the rural provinces to the capital, and Europeans first encountered it in the 16th century in the grand markets of Tenochtitlan. Cochineal, along with silver and logwood, quickly became one of the most lucrative exports of New Spain. The Spanish prohibited export of the live insects and maintained a monopoly on cochineal until the beginning of the 19th century. After the Mexican Revolution a few bugs were smuggled to Spain’s Canary Islands, but the industry there collapsed when synthetic red dyes were invented just a few decades later. Today cochineal is primarily produced in the high deserts of Peru, where the climate is ideal for growing the cacti that cochineal need to survive.

Cochineal is available in a wide variety of forms, including many extracts produced with different colors, strengths, and purposes. The oldest and best-known form of cochineal extract is called carmine. Carmine is simply carminic acid that has been solidified as a pigment or color lake, often with alum, although a variety of different methods are used some of which are very different from the methods used to produce plant-based pigments (see discussion in Crookes 1874:358-360). Carmine seems to have been invented by a Franciscan monk in Italy and it was well known in Europe by the middle of the seventeenth century, where it was chiefly employed for printing calicos and dyeing thin silks (ibid:359). The advantage of carmine is that it expresses the bright red color of cochineal combined with aluminum (pure carminic acid is a dull brown-purple color); the disadvantage of carmine is that, since it is a pigment or lake, it is not entirely soluble except at high pH. Nonetheless carmine remains the most common form of cochineal extract in use today and it is widely distributed in food (soft drinks, candies, sausages), cosmetics (lipstick, creams and ointments) and the arts (oil paints, soaps).

Cochineal C.A. Plus™ is a new form of cochineal extract that contains carminic acid in its most soluble form, without the addition of any precipitating agent like alum or calcium. That makes it easier to dissolve, easier to apply to textiles, and more sensitive to changes in mordants and pH. Indeed, Cochineal C.A. Plus can be used in much the same way as a decoction of raw cochineal, although it may produce a slightly cooler shade of red. It will yield intense pinks, crimsons, or fuchsias when dyed on an aluminum mordant, or lilacs and purples on iron. The color can also be shifted by adjusting the pH of the dyebath or “saddening” with a second mordant. Unless you prefer to use traditional carmine (see our Cochineal Extract Carmine) for historic reasons or for specific purposes like steam-printing, we recommend using Cochineal C.A. Plus for dyeing textile fibers like wool, cotton and silk. This is a very strong extract and it will give a good cherry red at 2% weight-of-fabric, or rich pinks at 0.5%. See below for recipes, tips, and important safety precautions.

Cochineal and Its Many Extracts

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Open carefully to avoid spills or creating dust.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Cochineal Extract C.A. Plus™ powder, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

4. Preparation: Pre-Mordant with Alum

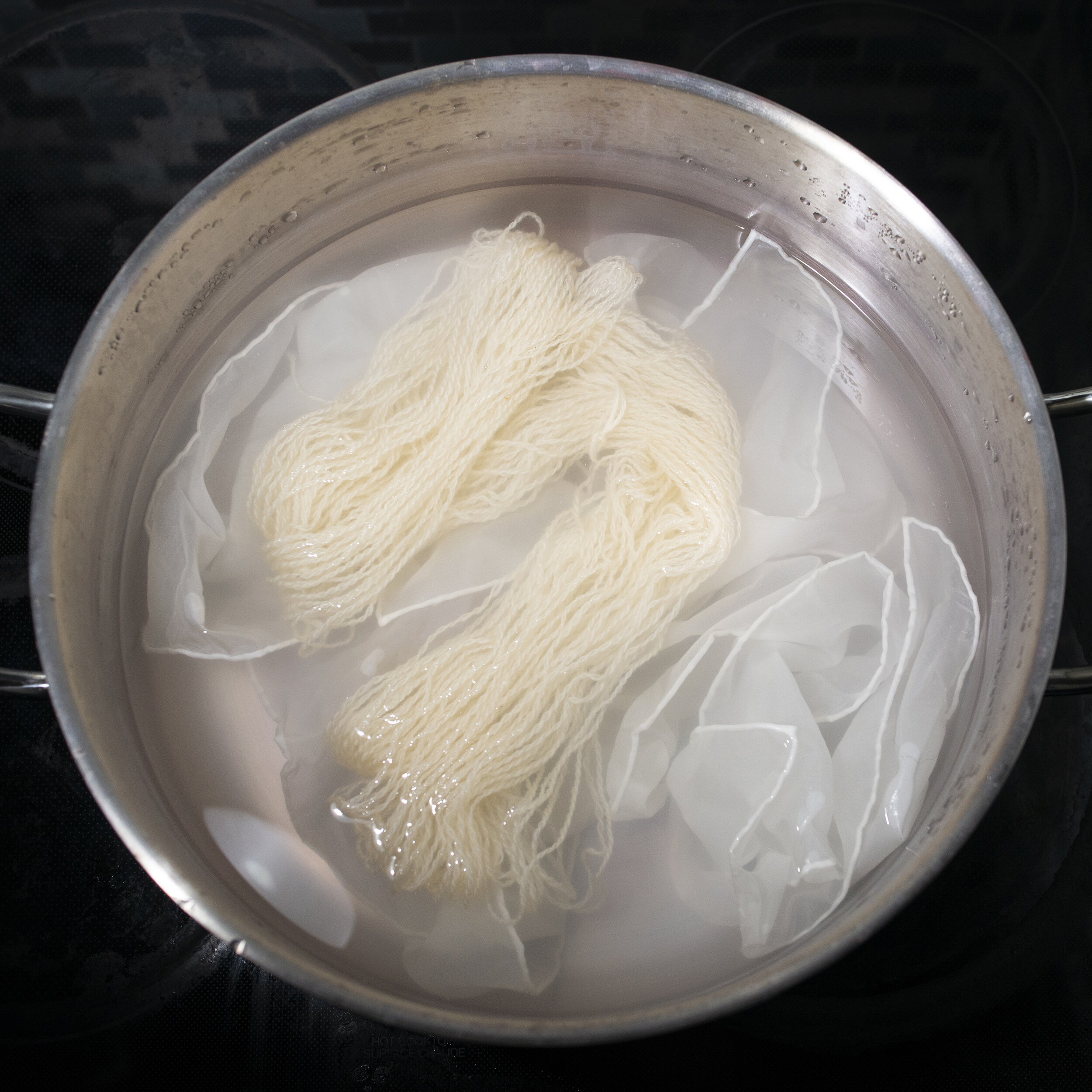

Cochineal C.A. Plus™ requires the use of a mordant for the best results. With alum, it produces shades ranging from pink to rose to crimson. Make sure your fibers are fully wetted through before they go into the mordant bath, so that the mordant penetrates them deeply and evenly.

For wool: Mordant with 12% WOF alum and 12% WOF cream of tartar.

Weigh out woollen fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum and cream of tartar you will need.

Scour the wool before mordanting. Fill a dye pot with enough warm water for your fibers to move around freely. Add 1 tsp of pH-neutral soap per pound of wool being scoured (we use Synthrapol). Raise the heat to 180F and maintain for an hour. After an hour, turn off the heat and let the wool cool until it is safe to handle. Transfer to a hot rinsing bath and rinse in one or two changes of water until all soap suds are rinsed out.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of cream of tartar and pour it into the pot. Mix well until dissolved.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your woolen fibers into the mordanting solution.

Heat mordant bath to 190F and maintain heat for 1 hour. Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool until safe enough to handle.

When ready to rinse, transfer the woolen fibers to a hot rinsing bath (without any soap). Rinse well in one or two changes of hot water to remove excess mordant and cream of tartar.

Dispose of the mordant solution according to local guidelines.

For silk: Mordant at 12% WOF with alum.

Weigh out the silk fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum you will need.

Scour the silk before mordanting. Fill a dye pot with enough warm water for your fibers to move around freely. Add 1 tsp of pH-neutral soap per pound of silk being scoured (we use Synthrapol). Raise the heat to 160F and maintain for an hour. After an hour, turn off the heat and let the silk cool until it is safe to handle. Transfer to a hot rinsing bath and rinse in one or two changes of water until all soap suds are rinsed out.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 160F and maintain heat for 1 hour. Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Steep for 12 hours or overnight in the mordant bath. Move the silk fibers around occasionally to make sure that no resists form (areas like folds or ties where the mordant does not penetrate as well).

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers well in lukewarm water.

For best results, do not allow the mordanted silk to dry out all the way before it is dyed; this may result in an uneven or splotchy dye job.

Dispose of the mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Treat with 20% Sumac Extract and then mordant with basic alum.

The carminic acid in cochineal does not have a great affinity for plant fibers like cotton and linen, and traditionally cochineal was not much used for dyeing cotton (see e.g. Hummel 1885:348). Cochineal C.A. Plus can be applied to plant fibers, but success will depend entirely on the thoroughness of the mordanting operation. We recommend mordanting with basic alum (see instructions below) for best results.

Scour cellulose fibers well. Traditionally this is done in an alkaline soda ash solution. Add 1 tsp of soda ash and 1 drop of dish soap to a dye pot full of warm water. Add cellulose fibers and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Tan the cotton: fill your dye pot with just enough hot water for the fibers to move around freely and dissolve 20% WOF Sumac Extract into the water. Add your scoured cotton, raise the temperature to 200F, and maintain for one hour. Remove from heat and allow to cool for at least 3 hours. For best results, steep overnight. This process will make the cotton or linen more receptive to mordants. Afterwards, gently wring out the cotton (just enough so it does not drip everywhere) but do not rinse it, as doing so could wash out some of the tannins that are soaked into the fibers.

Hang the tanned cotton up somewhere and let it dry completely. This will help fix the tannins to the fiber before mordanting. However, be careful to hang it up in such a way that there are no folds in it — otherwise you may get an uneven dye job.

Mordant with basic alum: Fill a dye pot with just enough lukewarm water for your fibers to move around freely. Measure out 20% WOF of alum, add to the pot, and stir well until dissolved. In a separate container, dissolve 4% soda ash in lukewarm water. Slowly add the dissolved soda ash to the dissolved alum, stirring constantly, until completely mixed: the solution will become slightly milky and opaque (do not add soda ash powder directly to the dissolved alum! — it will fizz up and then solidify as little particles). Once mixed, place the tanned cotton in the solution of basic alum and let it steep for one hour, stirring occasionally to make sure it mordants evenly. It is not necessary to add heat; in fact heating may cause the basic alum to precipitate as little particles. After an hour, remove the cotton, rinse well, and proceed to dyeing.

The Recipes

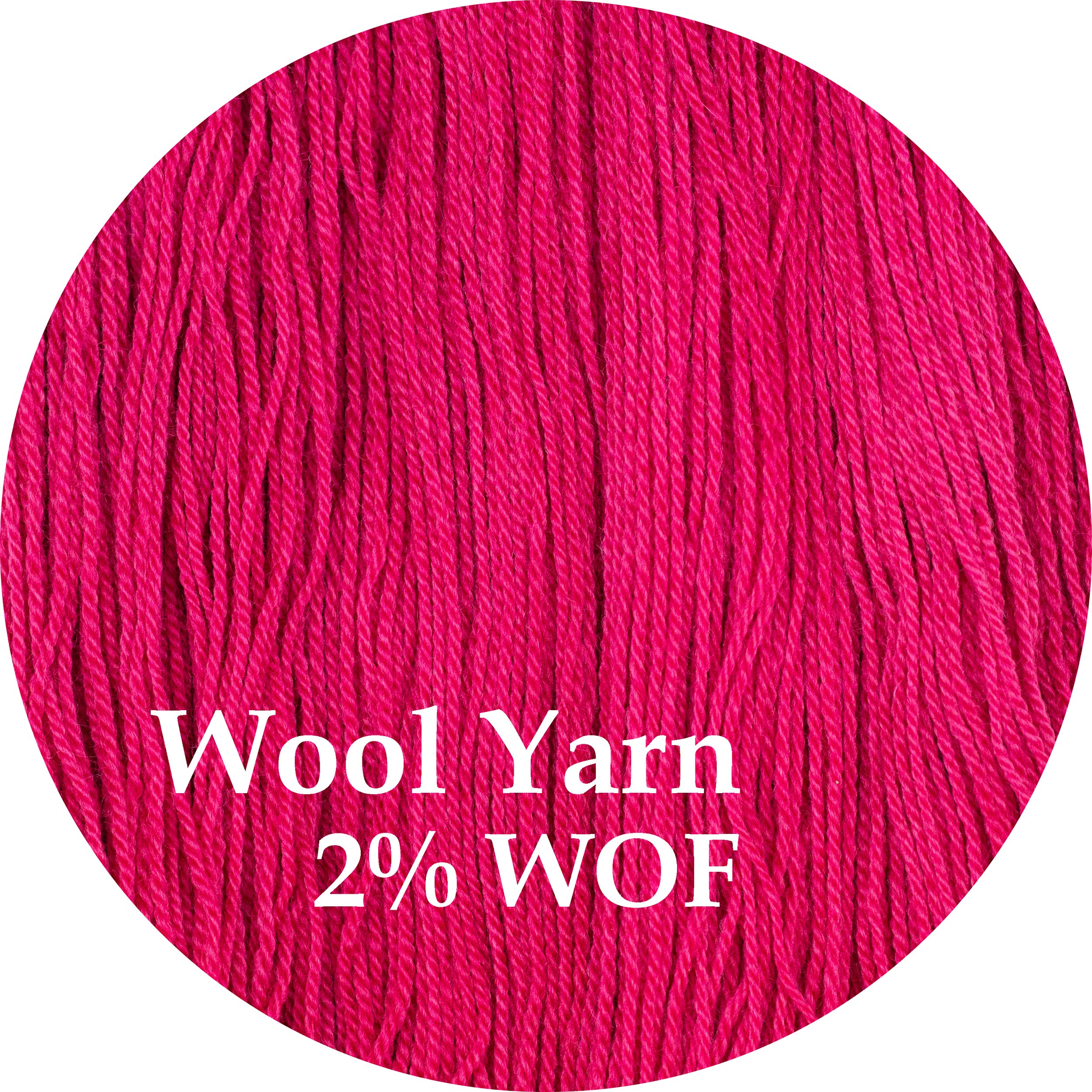

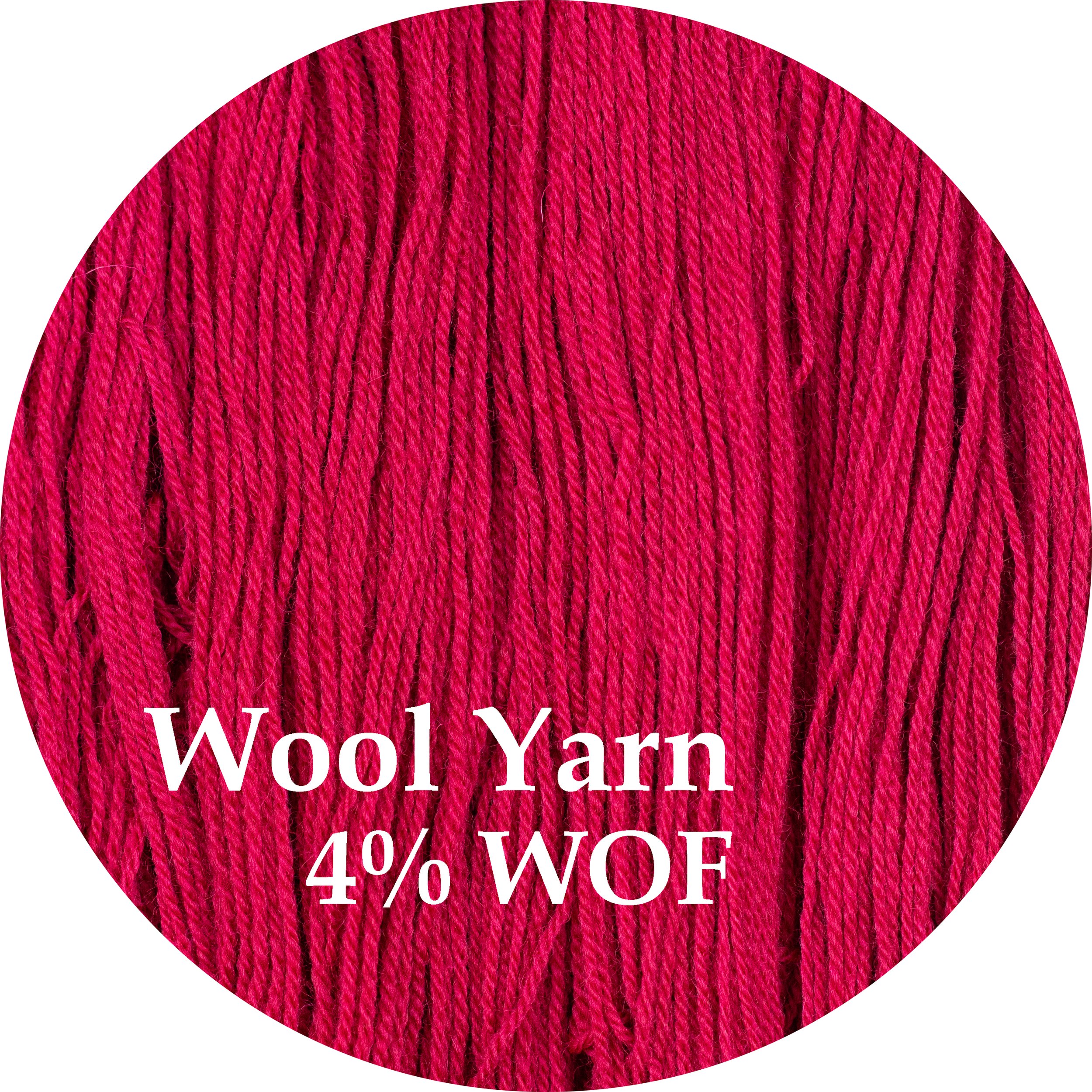

5. Recipe: Cherry Red on Woollens

Cochineal C.A. Plus™ will deliver a variety of beautiful shades of cherry red on wool that has been mordanted with alum. At 0.5% weight-of-fabric the color is a very intense pink; at 2% a cherry shade; and at 4% more of a classic crimson. We don’t recommend using more than 4% as the dyebath will become very concentrated and the wool will become increasingly difficult to rinse completely clean. Note that unlike some other natural dyes (for example, madder or logwood) cochineal will not fix to the fiber at a low heat so the dye bath will need to get hot and stay hot for the entire period. Cochineal also will not bond well to the fibers in hard or alkaline water, so we recommend adding some cream of tartar to the dye bath to increase absorption and brighten the color.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of Cochineal Extract C.A. Plus powder. Use 0.5% for pink, 2% for cherry, or 4% for crimson. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn a very dark red.

[Optional] Acidify the dye bath by adding 1 gram of Cream of Tartar per gallon of water in the bath. This will shift the color to a brighter, warmer red; it will also increase dye absorption. This is especially important if your water source is hard or alkaline [see note*].

Add your wetted, alum-mordanted wool to the dye bath.

Heat the dyebath to 200F and maintain for 1 hour, stirring occasionally to make sure all the wool dyes evenly. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal C.A. Plus may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*Note: More than probably any other natural dye, cochineal is highly averse to hard or alkaline water. Most municipal water sources should be soft enough to work with cochineal, although the water may need to be “corrected” by adding Cream of Tartar or white vinegar. However, if your water is extremely hard — as happens occasionally with wells in areas with a lot of calcium in the rocks — it may not be possible to get good results with Cochineal C.A. Plus. If this is the case, your best options are either to use a different water source for the dye bath (for example bottled distilled or filtered water) or to play to your strengths and choose a different red dye that works well with hard water, such as Wild Madder Extract.

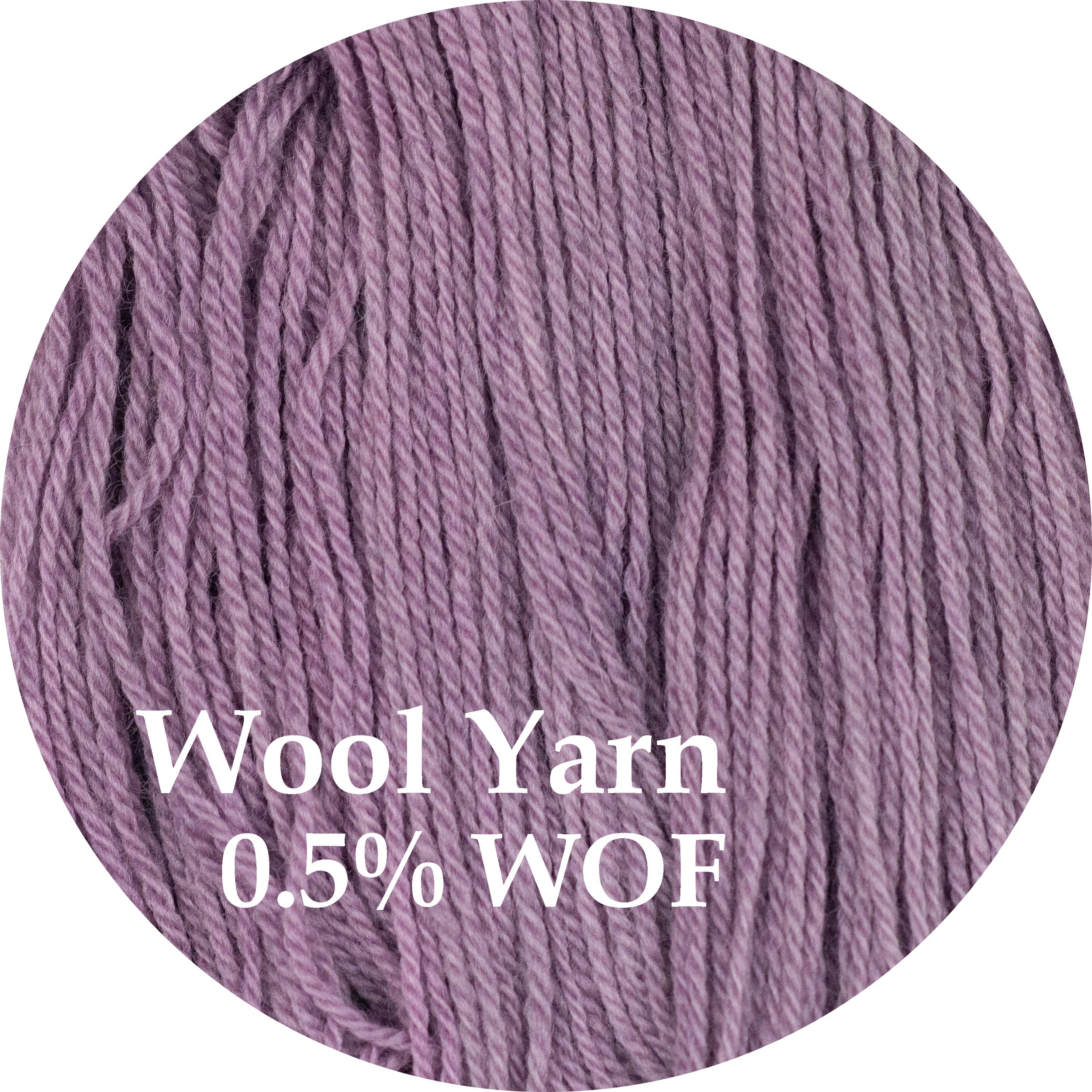

6. Recipe: Lilac on Woolens

Cochineal C.A. Plus™ will change colors when different mordants are applied. Using iron instead of alum will shift the color to a beautiful purple, ranging from a soft lilac to a deep royal purple. Don’t forget to add the 15% cream of tartar to the mordant bath, otherwise the iron may cause the wool to take on a brown undertone which will show up even after dyeing.

Follow the recipe for Cherry Red for Woolens. However, instead of using wool that is mordanted with 12% alum and 12% cream of tartar, use wool that is mordanted with 8% iron and 15% cream of tartar (follow the same mordanting instructions in Section 4 but substitute the iron for the alum).

7. Recipe: Rose on Silk

C.A. Plus™ delivers a more purplish shade of red on silk mordanted with alum, tending toward rose or fuchsia. Thicker weights of silk will take up dye quite similarly to wool. However, if you are dyeing very thin silk like silk satin the color will come out lighter because the silk is nearly transparent. If you want a dark color, you may need to increase both the amount of mordant and the amount of dye.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 4% weight-of-fabric (WOF) of Cochineal Extract C.A. Plus powder. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn a very dark red.

[Optional] Acidify the dye bath by adding 1 gram of Cream of Tartar per gallon of water in the bath. This will shift the color from a cooler red to a warmer red; it will also increase dye absorption. This is especially important if your water source is hard or alkaline.

Add your wetted, alum-mordanted silk to the dye bath.

Heat the dyebath to 180F and maintain for 1 hour, stirring occasionally to make sure all the silk dyes evenly. After 1 hour, turn off the heat and allow to cool.

When the silk is cool enough to handle, remove and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of silk (we use Synthrapol). A good soaping will not only clean the silk, it will also help to restore some of its luster. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal C.A. Plus may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

8. Recipe: Rose on Cotton

The carminic acid in cochineal has little natural affinity for plant fibers like cotton. However, it can still be successfully applied to cellulose fibers so long as they have been very thoroughly mordanted. The resulting shade is a fuchsia or rose pink, although other shades can be produced by adjusting the pH of the dye bath.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 2% weight-of-fabric (WOF) of Cochineal Extract C.A. Plus powder. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn a very dark red.

Add your wetted, alum-mordanted cotton to the dye bath.

Heat the dyebath to 200F and maintain for 1 hour, stirring occasionally to make sure all the cotton dyes evenly. After 1 hour, turn off the heat and allow to cool.

When the cotton is cool enough to handle, remove and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of cotton (we use Synthrapol). Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Cochineal C.A. Plus may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.