Flavin™

A Guide to Flavin™

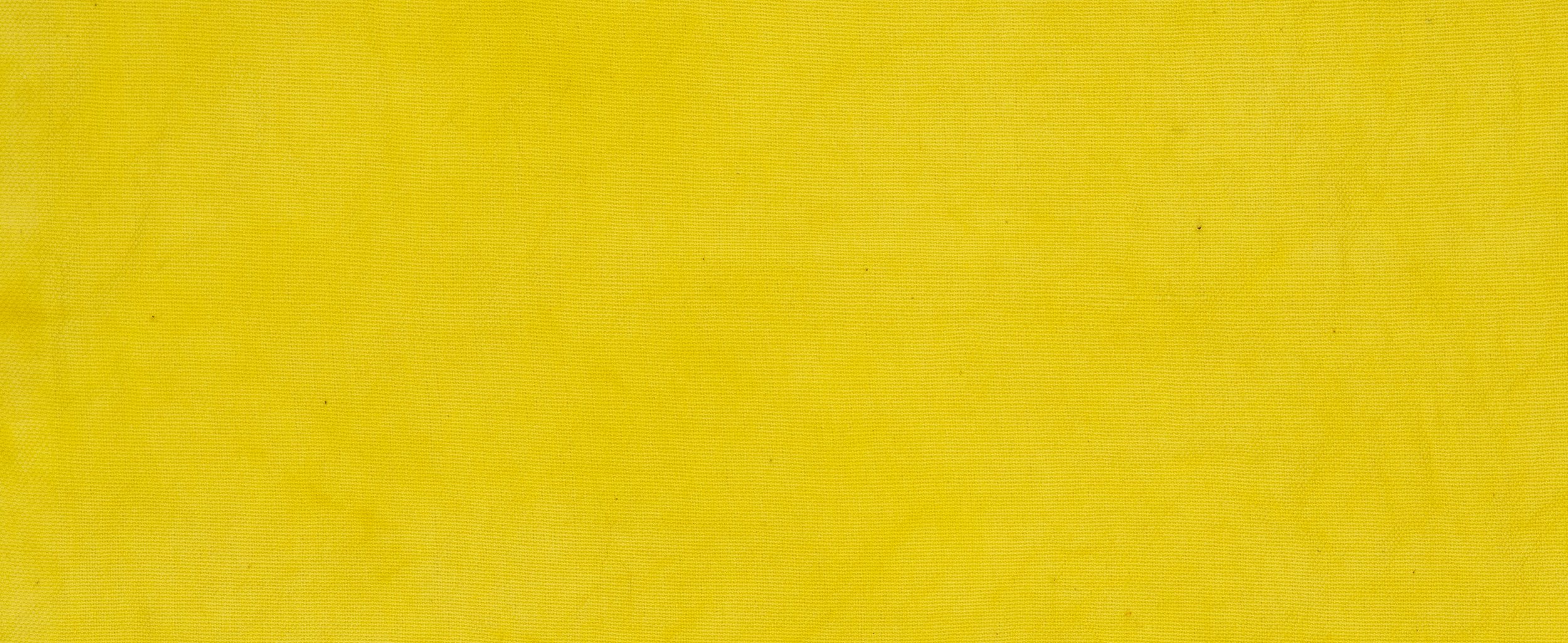

Shepherd Textiles Flavin™ natural dye is made from the flower buds of sophora japonica, the Japanese pagoda tree. Pagoda tree buds are rich in a yellow pigment called quercetin that gives bright canary yellow shades on natural fibers. Quercetin was actually the favorite yellow of American dyers in the 18th and 19th centuries, when the same pigment was extracted from the inner bark of the black oak. Victorian chemists speculated that this pigment was the foundation of all the yellow plant flavonoids. Flavin™ is a powerful dye that will give saturated colors with 5% weight-of-fabric. It contains the same yellow dyestuff that early Americans preferred, but is sustainably sourced from annual flowers rather than by felling mature trees.

1. Background on Sophora Japonica

The story of Flavin is actually the story of two different dyestuffs: the black oak, quercus velutina, and the pagoda tree, sophora japonica.

The black oak is native to the eastern United States, from Maine to as far south as Florida. It was an important dye for the early American colonists who learned, probably from Indigenous peoples, that the inner bark could be simmered to produce a yellow color on textiles. Because this dye came from an oak, it was called quercitron. Quercitron offered colonial dyers an attractive alternative to weld (which was the favored yellow in continental Europe) and old fustic (which was popular in England, where it was imported from Caribbean colonies). Quercitron was widely available in American markets in the form of a fine powder (Knecht 1910:353), and it was such an effective dye that it quickly became an object of international commerce - English dyers all agreed that the best variety was imported from Philadelphia (ibid; Crookes 1874:395). By the late 19th century, American inventors had patented several processes for purifying quercitron to remove the woody matter and tannins and isolate pure quercetin, the active pigment in the black oak (Crookes 1874:402). This extract was known to dyers as flavin (Knecht 1910:354) and it was reputed to be one of the strongest of all the yellow dyes. However, quercitron and flavin fell out of use in the early decades of the 20th century due to competition with synthetic aniline dyes and overlogging of mature black oak trees.

The pagoda tree, sophora japonica, is a small deciduous tree native to China that blossoms with thousands of tiny white flowers every summer. Those flowers are considered to be one of the 50 foundational herbs of Traditional Chinese Medicine. In general their indications include “cooling blood, stopping bleeding, clearing liver, and purging fire” (Wei et al. 2018:n.p.). They are also understood to have different medicinal properties depending on when they are harvested; immature buds picked in the spring have the highest flavonoid content (up to 20% by weight) and are prescribed as a blood tonic; flowers picked later in the year are said to be good for intestinal illnesses (Tang & Eisenbrand 1992:945). The high flavonoid content of the immature buds is mostly made up of quercetin - coincidentally, the same yellow pigment that chemists isolated from black oak in the 19th century.

Shepherd Textiles Flavin™ is a highly concentrated extract of sophora japonica that reproduces the dyestuff that early Americans preferred when dyeing yellow. It also has the advantage of being ecologically sustainable, since it does not require the felling of old growth trees to get the yellow pigment. Use at 5% weight-of-fabric for extremely bright yellows or oranges, or use as a base for overdyeing to get an enormous variety of intense shades.

Nature’s Foundational Yellow

2. Safety Precautions

DO NOT INGEST. Flavin™ is intended for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Wear a mask while weighing and mixing the powder; avoid inhaling the fine powder.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation. Flavin™ will stain stainless steel dye pots, and a scouring pad may be required to clean them.

Flavin™, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Tin mordant. Otherwise known as stannous chloride, tin mordant is used to get orange shades with Flavin™.

4. Preparation: Mordanting with Alum

Flavin™ requires a metal mordant for the best results. For bright canary yellows, pre-mordant the fiber with alum as described below (note that some color recipes use an alternative mordanting process - check each recipe for details). If possible, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

For wool fibers (wool, alpaca, etc.): Mordant with 10% alum and 11% cream of tartar.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.10 to calculate the amount of alum you will need, and 0.11 to calculate the amount of cream of tartar.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of cream of tartar and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Next, weight out the correct amount of alum and add it to the dye pot. Mix until well dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180°F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180°F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. Otherwise, an uneven dye job may result.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results when dyeing thick yarn or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers well in lukewarm water. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For silk: Mordant with 15% alum.

Follow the directions for mordanting wool described above. However, use 15% alum and omit the cream of tartar.

For cellulose fibers (cotton, linen, etc.): Treat with a tannin before mordanting.

Flavin™ will give strong yellow shades on cotton, but the cotton should be well tanned and mordanted before dyeing.

Scour (clean) the cotton by adding 2 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with just enough hot water for your fibers to move around freely - the more concentrated the tannin bath, the stronger the results will be. Dissolve 20% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they can bond to the mordant. For the strongest results, hang the cotton up and let it dry before proceeding to mordanting.

Prepare an alum mordant bath using either (a) 20% weight-of-fabric alum + 5% weight-of-fabric soda ash (washing soda), or (b) 20% weight-of-fabric of aluminum lactate. Either option will create a relatively neutral pH mordant bath that bonds well with cotton.

Heat the mordant bath to 150°F or 160°F, place the cotton in it, and raise the heat to 190°F. Maintain for one hour, stirring occcasionally to make sure the fibers mordant evenly. After one hour, remove from heat. When cool enough to handle safely, remove fibers and rinse well in lukewarm water.

The Recipes

5. Recipe: Canary Yellow

At just 5% weight-of-fabric, Flavin™ will produce a deeply saturated canary yellow shade on alum-mordanted fiber- the color is especially intense on wool and cotton. Indeed, Flavin™ has such a strong attraction to mordants that the dyebath will sometimes exhaust itself onto the fiber in as little as half an hour. This is one of the very strongest of the natural yellows, but a word of caution - Flavin™ will stain stainless steel, so you may need a scouring pad to clean your dye pot when you are finished working with it.

Fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 5% weight-of-fabric (WOF) of Flavin™ powder and put it in a disposable cup with a little warm water. Mix vigorously to make a slurry - the powder will want to clump up and sit on top of the water and it will require some work to dissolve it. Once mixed, add the slurry to the dye pot.

Next, add your alum-mordanted fiber to the dye bath.

Raise the temperature gradually to 180°F for silk or 190-200°F for wool and cotton, then maintain for 1 hour. Stir occasionally to make sure everything dyes evenly**.

After 1 hour, remove pot from heat and allow to cool until the fiber can safely be handled.

Remove the fibers and rinse well in warm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Flavin™ will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

**NOTE: You may not need the full hour. If the color all exhausts onto the yarn and the dye bath is mostly clear, give it another ten minutes or so to make sure the color is set, and then if you like you can remove the fibers and proceed to the initial rinsing.

6. Recipe: Olive Green

After dyeing yellow with Flavin™, the fibers can be saddened with iron to produce an olive green shade.

Follow the directions for “Canary Yellow” in Section 5. However, after the dyeing is complete (Step 5), remove the fibers and rinse briefly in water, but do not proceed to the final rinsing and washing with detergent.

Prepare an iron saddening bath: Fill a dye pot with enough warm water for your fibers to move around freely. Measure out 2% weight-of-fabric of iron mordant (ferrous sulfate) and add dissolve in the warm water. Raise the temperature of the saddening bath to about 120 or 130°F.

Place your yellow-dyed fibers into the saddening bath and raise the temperature to 190°F. Maintain the temperature for 20 minutes, stirring occasionally to make sure the fibers sadden evenly.

After 20 minutes, turn off the heat. As soon as the fibers are cool enough to handle safely, remove and rinse well to remove any excess iron. Wear rubber gloves when handling the fiber until it has been completely rinsed.

Hang the fibers up to dry in the shade.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Flavin™ will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

7. Recipe: Neon Orange

With a tin mordant, the color of Flavin™ shifts toward orangier shades. Tin can be applied as a pre-mordant, but many dyers in the past preferred to apply it in a single bath with the mordant, the dye, and the wool all in one pot. This method produces strikingly bright shades. However, the fibers need to be very well scoured before they go into the dye bath, or an uneven dye job may result. Tin can also be a bit harsh on wool in a single bath, so using more than the 5% called for here is not recommended. Note that this recipe will work on wool and silk, but not on cotton.

Fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 4% weight-of-fabric (WOF) of cream of tartar and add to the dye pot. Mix well until fully dissolved. Next, measure out 5% WOF of tin powder (stannous chloride) and add to the dye pot. Mix well until fully dissolved.

Add your well-scoured, wetted, unmordanted fiber to the dyebath.

Raise the temperature to 180°F for silk or 190-200°F for wool, then maintain for 30 minutes. Stir occasionally to make sure the fiber mordants evenly.

Meanwhile, measure out 5% weight-of-fabric (WOF) of Flavin™ powder and put it in a disposable cup with a little warm water. Mix vigorously to make a slurry - the powder will want to clump up and sit on top of the water and it will require some work to dissolve it.

After the fibers have mordanted for 30 minutes, remove them from the dye pot with tongs and set aside (in an empty dye pot, if possible). Pour the Flavin™ slurry into the dye bath and mix well. Give it a minute or two to make sure the color is evenly dissolved into the dye bath.

Return the fibers to the dye bath and maintain the temperature for another 30 minutes, stirring occasionally to make sure everything dyes evenly.

After 30 minutes, turn off the heat and allow the dye bath to cool until the fibers can safely be handled.

Remove the fibers and rinse in warm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Flavin™ will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

8. Recipe: Fiery Scarlet

By the middle of the 19th century, it was standard practice for professional dyers to add a little yellow when dyeing scarlet in order to increase the fiery shade of the red. The pigment in Flavin™ was often the preferred yellow for this purpose. Flavin has an affinity for tin mordants and for single-bath methods, both of which are essential to dyeing scarlet. This recipe is adapted from a 19th-century dyeing manual, and was considered to be one of the most intense reds achievable with natural dyes. Note that it requires oxalic acid, which is caustic and harmful if ingested or inhaled - do not attempt this recipe unless you have a respirator mask and an outdoor dyeing setup to help disperse the fumes.

Fill your dye pot with enough warm water for your fibers to move around freely.

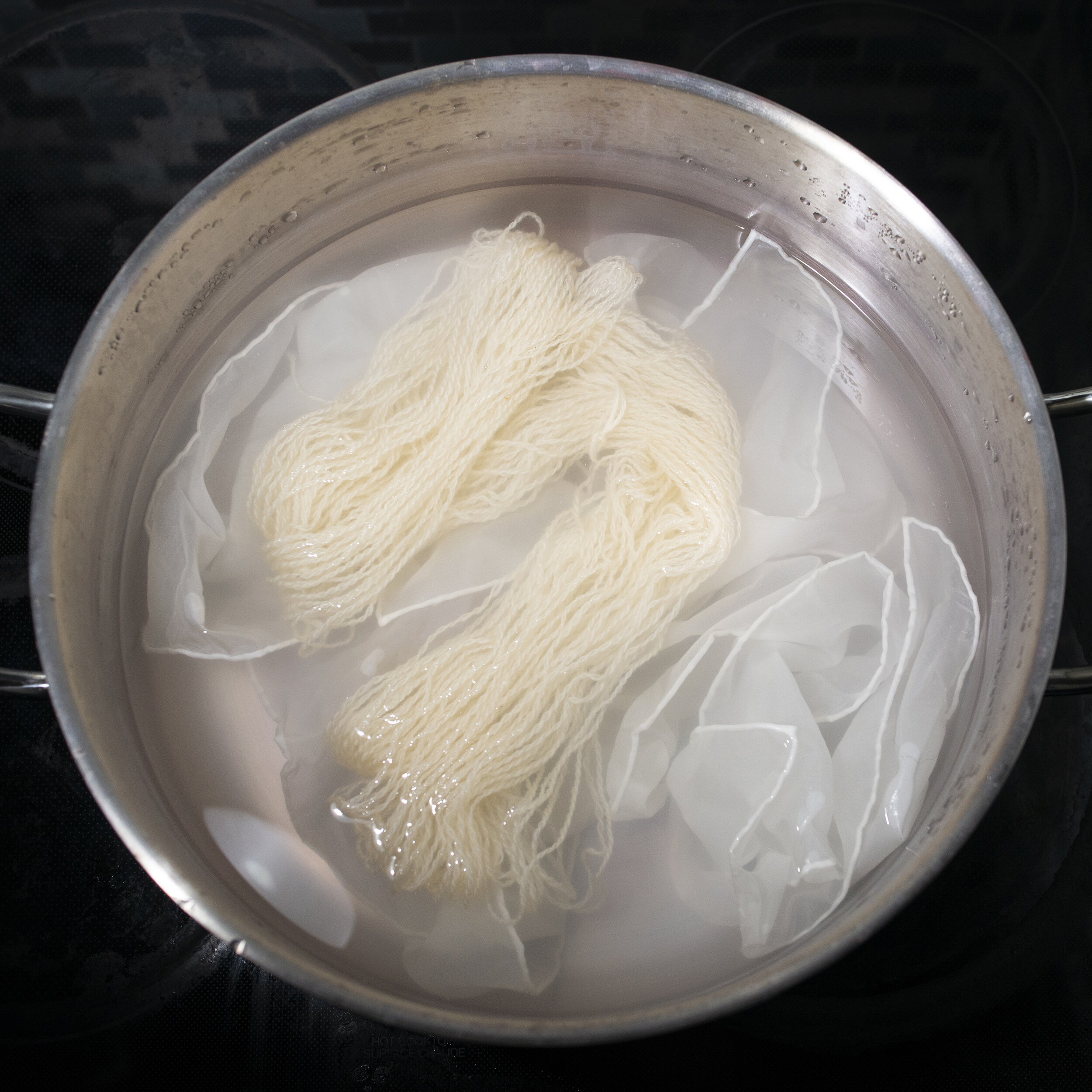

Add 20% weight-of-fabric of ground cochineal (to make life easier, put the ground cochineal into tea bags or a muslin dye bag and tie shut - this is easier than trying to filter out the tiny bits of cochineal powder). Raise the temperature to 190°F and simmer for 30 minutes to extract the color. Let cool until safe to handle.

Filter out the ground cochineal (or remove the tea bags, if used).

Measure out 1% weight-of-fabric (WOF) of Flavin™ powder and put it in a disposable cup with a little warm water. Mix vigorously to make a slurry - the powder will want to clump up and sit on top of the water and it will require some work to dissolve it. Add the slurry to the dye bath.

Measure out 6% weight-of-fabric of oxalic acid**. Add to the dyebath and mix well.

Measure out 6% weight-of-fabric of tin (stannous chloride). Add to the dyebath and mix well.

Add your well-scoured, wetted, unmordanted wool to the dyebath.

Gradually raise the temperature to 190-200°F for wool, then maintain for 45 minutes. Stir occasionally to make sure the fiber dyes evenly. Wear a full-face respirator to avoid breathing oxalic acid fumes.

After 45 minutes, turn off the heat and allow the dye bath to cool until the fibers can safely be handled.

Remove the fibers and rinse well in warm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Flavin will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

Note: The quantities used here produce a very dark shade of red. For a brighter scarlet, reduce the proportions to 15% cochineal and 0.5% Flavin™. The amount of tin and oxalic acid remain the same.

**Caution: Oxalic acid is toxic if ingested and can cause chemical burns if it touches the mucuous membranes. Do not ingest; avoid contact with skin, eyes, mouth, and nose. Do not inhale fumes from the hot dye bath. Wear gloves when handling the dye bath or fiber coming out of the dye bath until it has been rinsed. If ingestion or inhalation occurs, contact a poison control center immediately. Read your manufacturer’s SDS (Safety Data Sheet) before using oxalic acid and observe all recommended safety precautions. Do not attempt this recipe unless you have an outdoor dyeing setup and full protective gear, including rubber gloves, eye protection, and a respirator mask (this is the one we use). Dispose of the spent dye bath safely according to local regulations. Store oxalic acid and dye baths containing oxalic acid away from children and pets. Shepherd Textiles is not responsible for any adverse effects of dyeing with oxalic acid.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.