Gambir Extract

A Guide to Gambir Extract

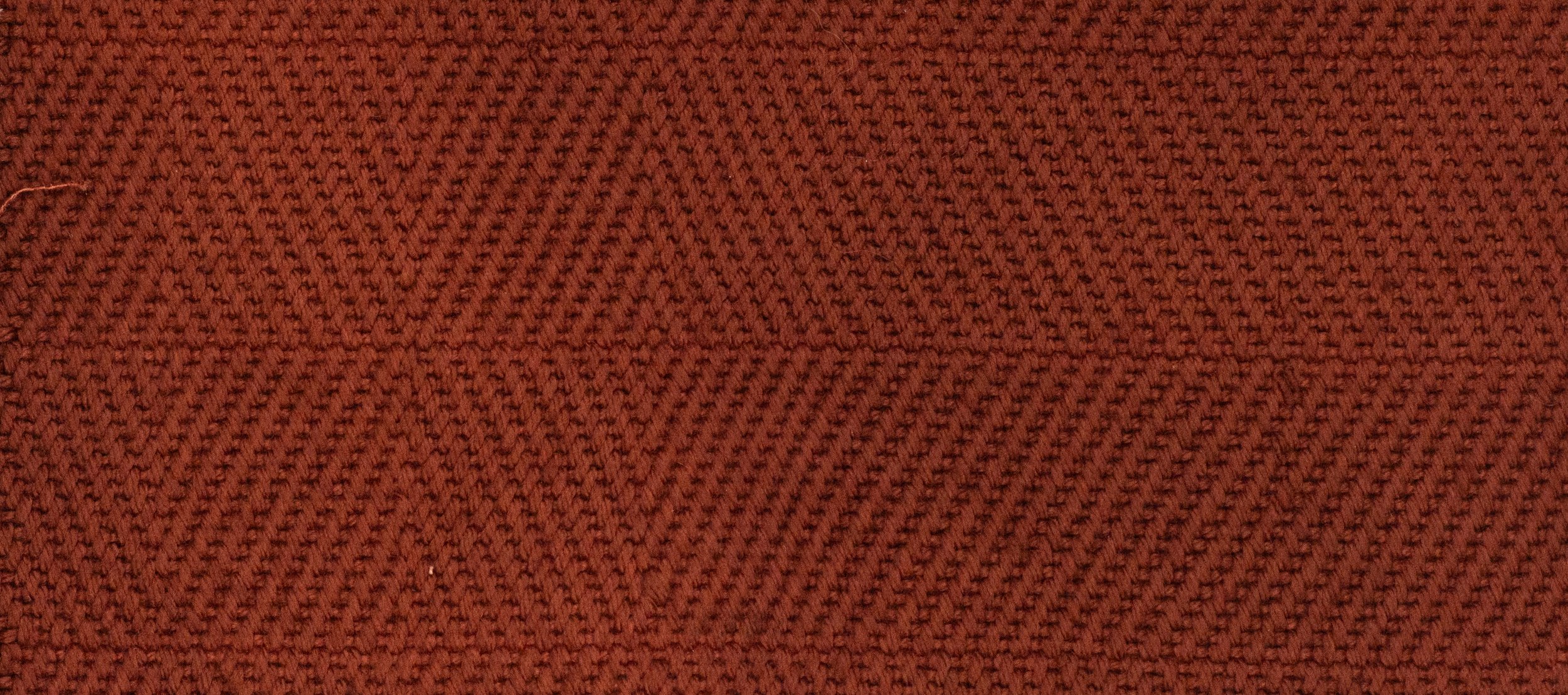

Shepherd Textiles Gambir Extract natural dye is made from uncaria gambir, a shrubby tree native to the rainforests of Malaysia and Indonesia. The leaves and branches are steamed until a thick paste begins to be released from them. This is collected, concentrated, and dried in frames until it becomes hard chunks of Gambir Extract. Gambir is rich in catechu tannins and with proper mordanting the color will develop into fantastic shades of mahogany or chocolate brown. Use at 20% weight-of-fabric for dark shades, and 5-10% for lighter browns. Note that Gambir Extract comes in the form of hard, glassy chunks rather than a fine powder. However, the chunks will dissolve in hot water.

1. Background on Gambir

Gambir Extract is derived from the leaves and branches of uncaria gambir, a small tree that grows in the rainforests of South and Southeast Asia, from India through the Indonesian islands. Gambir extract is collected by steaming the leaves and branches of the tree until a thick, tannin-rich paste begins to sweat out of them; this is collected and dried in frames where it darkens into the hard, solid substance known as gambir. Gambir has many similarities to cutch, but it never became as widespread because it was more difficult to commercialize; the only real gambir industry developed on a small scale in Indonesia.

Almost all dyeing manuals from the 19th and early 20th centuries treat cutch and gambir together because their dyeing properties and colors were considered to be very similar. Both cutch and gambir contain catechutannins as their primary dyestuff. However, gambir was understood to contain a less oxidized form of catechutannic acid (Knecht 1910:369), which made it especially suitable for dyeing by the “stuffing and saddening” method. In stuffing and saddening (post-mordanting), the fiber is first simmered in the dyebath until it is “stuffed” or completely soaked through with the dyestuff, and only then is it transferred to a separate mordanting bath. When an oxidizing mordant like copper is used, the results on gambir are especially dramatic: the unoxidized tannins are converted to an insoluble form called japonic acid and give the fiber a dark, permanent color. Gambir was commonly used for dyeing cotton and dark shades on silk. Although it was less commonly used on wool, many dyeing authorities agreed that on wool “it is capable of yielding fine rich brown colours, which are fast to milling, scouring… and also to light” (Hummel 1885:370).

Shepherd Textiles Gambir Extract is a high-quality Indonesian gambir that delivers very dark shades using 20% weight-of-fabric. Note that it arrives in hard, glassy, thumb-size chunks (and smaller pieces broken off those chunks). The chunks are difficult to break, but will dissolve easily in hot water. An excellent choice for all natural fibers; the reddish browns that develop with a copper mordant are a highlight.

The “Yellow Catechu”

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Gambir Extract, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Copper mordant. Copper mordant (copper sulfate) is a bright blue powder available from online marketplaces or pool supply stores.

Iron mordant. Iron mordant (ferrous sulfate) is sometimes labeled ferrous sulfate heptahydrate; it can be purchased from online marketplaces or specialist stores.

4. Preparation: Scouring

Gambir Extract is applied by stuffing and saddening (post-mordanting) rather than pre-mordanting, so no initial mordanting is required. The fibers should still be well cleaned before going into the dye bath - otherwise the dye job may turn out uneven.

For protein fibers (wool, silk, alpaca, etc.): Scour with pH-neutral detergent.

Scour protein fibers by adding 1/2 tsp of pH-neutral detergent (eg., Synthrapol) per pound of fiber to a 5-gallon dye pot. Add the fiber and heat to 160F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse well.

For cellulose fibers (cotton, linen, etc.): Scour with soda ash and soap.

Scour cotton by adding 1 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse well.

The Recipes

6. Recipe: Mahogany

Unlike most other natural dyes, Gambir Extract is applied by the “stuffing and saddening” method. The fibers are simmered in a concentrated solution of Gambir Extract so that they soak up as much of the gambir as possible, and then they are transferred to a copper mordant bath. The copper acts both as a mordant and oxidizing agent, converting the raw catechutannic acid to darker japonic acid and fixing it permanently on the fibers. The results are beautiful browns with a reddish mahogany hue.

Fill your dye pot with enough warm water for your fibers to move around freely. However, do not add more than is necessary - less water will create a more concentrated solution, which will help develop darker colors.

Measure out 20% weight-of-fabric (WOF) of Gambir Extract and add to the dye pot. Dissolve the Gambir Extract by stirring for a few minutes. Gently heating the dye bath will help big chunks dissolve faster, but be careful not to let any of them stick to the bottom and burn before they dissolve.

Add your unmordanted (but well scoured) fibers to the dye bath.

Raise the temperature to 180°F for silk or 190-200°F for wool and cotton, then maintain for 1 hour. Stir occasionally to make sure everything dyes evenly. This will “stuff” the fibers with gambir.

After 1 hour, remove pot from heat and allow to cool. For the darkest colors, let the fibers cool completely in the dye bath.

When you are ready to proceed, create a separate copper saddening bath. Fill a dye pot with enough warm water for your fibers to move around freely. Add 4% copper sulfate and mix well until combined. Heat the saddening bath to about 120°F or 130°F.

Remove your fibers from the gambir dye bath and let most of the excess liquid drip back into the pot. If there is a lot, you can squeeze some of the excess liquid out, but do not rinse the fibers*.

Add your fibers to the copper saddening bath and raise the temperature to 190F. Maintain for 30 minutes.

After 30 minutes, the fibers should be a rich brown shade. Remove them with tongs and rinse well. Hang them up to dry somewhere in the shade.

For a final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Gambir Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*NOTE: The logic behind this is that you do not want to introduce too much excess dye bath liquid into the saddening bath, because it will waste some of the copper mordant. However, you also do not want to rinse the fibers because that would rinse out a lot of the gambir that is soaked into them. A little dye bath liquid getting in is nothing to worry about, so do not go to too much trouble trying to squeeze the fibers completely dry.

TIP: So long as no mordants were introduced into the gambir dye bath, it can be reused multiple times. Simply add more fiber and start over again to get lighter shades of brown. Or, you can top off the dye bath by adding some fresh Gambir Extract to get darker shades again.

CAUTION: Copper mordant (copper sulfate) is harmful if ingested and may cause irritation of the skin, eyes, and mucuous membranes. Inhalation of copper sulfate dust may irritate the lungs. Read your manufacturer’s SDS (Safety Data Sheet) before using copper sulfate and observe all recommended safety precautions. Wear gloves, a mask, and eye protection when working with copper mordant, copper mordant baths, and fibers mordanted with copper that have not been rinsed. Store copper mordant and copper mordant baths out of reach of children and pets.

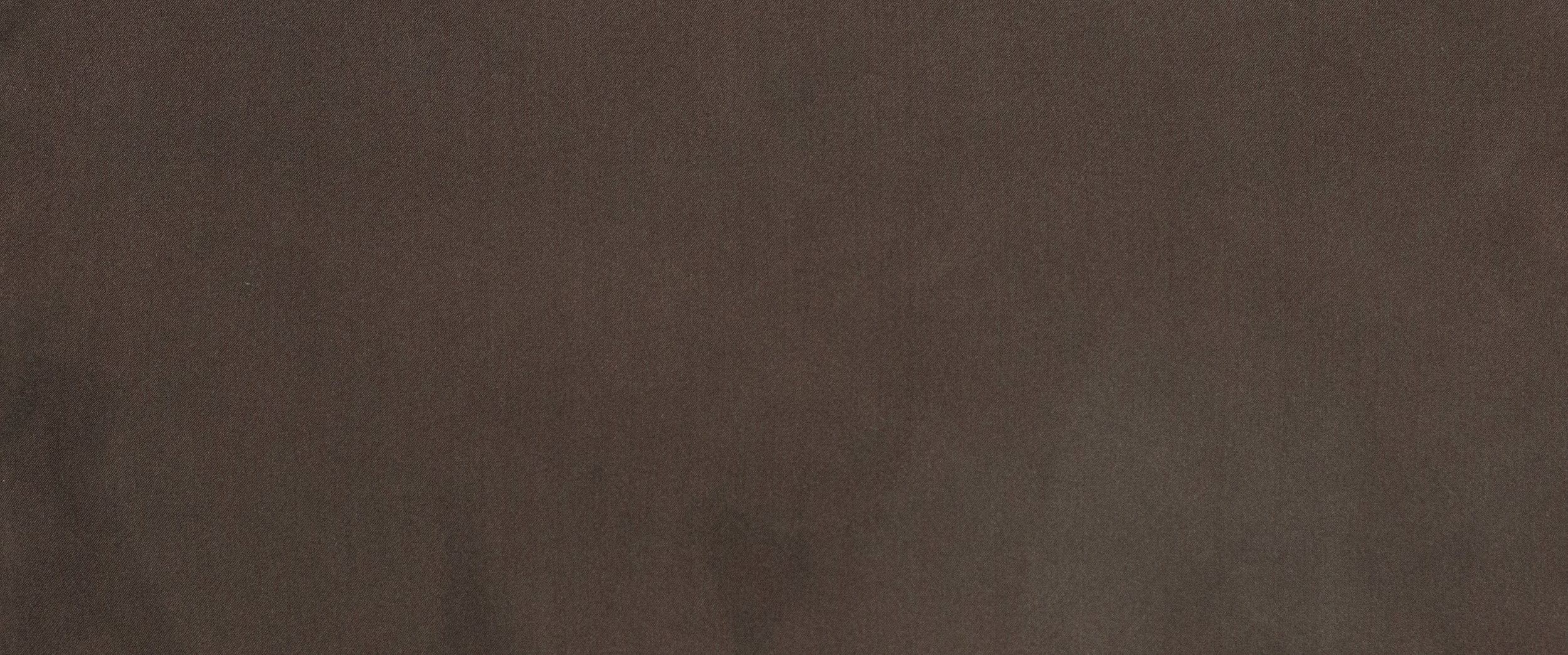

7. Recipe: Chocolate Brown

Changing the saddening agent from copper to iron will result in a very different shade of brown. It is darker and less reddish, closer to a chocolate shade. Otherwise, the recipe is exactly the same.

Follow the instructions for Mahogany in Section 6. However, when you reach the point of building the saddening bath (Step 6), substitute 4% iron (ferrous sulfate) for the copper. Continue with the recipe.

NOTE: Iron is much harsher on wool than copper is, so you do not want to leave wool in an iron saddening bath any longer than necessary. If your wool fibers “sadden” (turn dark brown) in less than 30 minutes, you can go ahead and pull them out of the saddening bath and rinse them. Loosely spun yarn may only need 5 or 10 minutes once the saddening bath reaches temperature; tightly spun yarn or tightly woven fabrics will need more. Cotton and silk are more resilient to iron and can withstand the full half hour in the bath.

CAUTION: Iron mordant (ferrous sulfate) is harmful if ingested and may cause irritation of the skin, eyes, and mucuous membranes. Inhalation of ferrous sulfate dust may irritate the lungs. Read your manufacturer’s SDS (Safety Data Sheet) before using ferrous sulfate and observe all recommended safety precautions. Wear gloves, a mask, and eye protection when working with iron mordant, iron mordant baths, and fibers mordanted with iron that have not been rinsed. Store iron mordant and iron mordant baths out of reach of children and pets.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.