Kusumi Lac Extract

A Guide to Kusumi Lac Extract

Shepherd Textiles Kusumi Lac Extract is an exceptional grade of natural lac dye. It contains highly concentrated laccaic acid, a red pigment extracted from the resin secreted by lac insects. Kusumi Lac Extract will dye rich shades of burgundy and ruby red on woolen fibers and silks using as little as 3% weight-of-fabric (WOF). An entire range of different colors, from soft lilacs to bright scarlets, can be achieved by adjusting the mordant and the pH of the dye bath. This is an extremely potent dyestuff that is highly water-soluble and easy to apply to wool and silk, although note that lac does not perform well in hard water and it produces softer strawberry shades on cotton and linen. Product of India.

1. Background on Kusumi Lac Extract

Lac (the dye) is a red pigment found in the waxy secretion of kerria lacca, a scale insect native to South Asia. Lac insects spend their lives on the branches of trees like Indian jujube or palash, feeding on the trees’ sugary phloem. Female lac insects in fact are almost entirely stationary on their host tree. They cover themselves in waxy resin and create a cell in which they can safely mature and eventually lay their own eggs. They simultaneously secrete a reddish pigment inside the cell, which is what gives lac resin its characteristic orange, red, or brown hue. After the eggs hatch, the larval lac insects emerge from inside the resin cells and travel along the branches of the host tree, sucking at its fluids and eventually settling down in one spot where they will begin to secrete their own resin and start the cycle anew. Lac is cultivated commercially by cutting off a branch covered with lac that is about to hatch, known as broodlac, and placing it on a new tree to colonize. Branches covered in lac resin that are cut down for harvesting are known as sticklac. Generally sticklac is soaked in water for a few days to soften the resin, which is then scraped off and refined by melting it and filtering out any solids or contaminants (Singh 2006:10). Eventually most sticklac will be refined into shellac, the purified resin that is used to coat furniture, instruments, candies, and even fruit like oranges.

The primary pigment extracted from lac resin is a red anthraquinone compound known as laccaic acid. Laccaic acid comprises anywhere from 2%-10% of raw lac resin by weight, and the pigment can be separated from the waxy substances through a simple acid-base extraction. Laccaic acid is structurally similar to the carminic acid that is found in cochineal insects, and indeed lac and cochineal behave very similarly in the dye bath. Both of the insect-based red dyes perform best in an acidic environment, they are both highly averse to hard water, and they produce equivalent shades when dyed on the same mordants. Hummel (1885:354) reports that Victorian experts dyed lac using the exact same methods that they would use for cochineal, however he notes that “Lac-dye reds are less brilliant than Cochineal reds, but possess greater intensity.” What the Victorians meant when they distinguished color descriptors like “brilliant” and “intense” is not always clear, but it is fair to say that cochineal reds can be a bit brighter whereas lac reds have more depth.

Lac was a historically important dye in South and Southeast Asia where the insect is native, and it was likely known to the Romans in antiquity through trade routes that passed through Persia and into India. By the Middle Ages, however, lac dye was virtually unknown to European dyers (Crace-Calvert 1872:206), and it was not imported in commercial quantities until the end of the 18th century (ibid:224). The invention of synthetic red dyes a few decades later made lac dye obsolete, although lac insects were still cultivated throughout South Asia for their valuable shellac resin. Today, lac production is an increasingly important economic project in rural India, where it provides an additional income source for many small farmers at the cost of a few sticks of broodlac. There are several strains of lac insect, several preferred host trees, and several annual harvests. The best quality comes from a strain of insects that prefers to colonize kusum trees and is known as kusumi lac. Shepherd Textiles Kusumi Lac Extract is named after this extra-fine grade of lac, and it contains very rich and concentrated laccaic acid in a highly water-soluble form. Like the other insect-based reds it gives softer results on cotton, but easily produces very fine reds of many shades on wool, and is certainly one of the most beautiful natural reds on silk. Use it at just 3% or 4% weight-of-fabric (WOF) for deep burgundy or ruby red shades on fibers mordanted with alum, or eggplant purples on fibers mordanted with iron. Product of India.

A Rich Insect Red

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Always wear gloves, a mask, and eye protection when working with dry pigment powders.

Work in a well-ventilated space. Avoid inhaling the steam or vapor from hot mordant baths and dye baths, and keep a lid on the dye pot when possible.

Open jar carefully to avoid spills or creating dust.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Kusumi Lac Extract powder, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

4. Preparation: Pre-Mordant with Alum

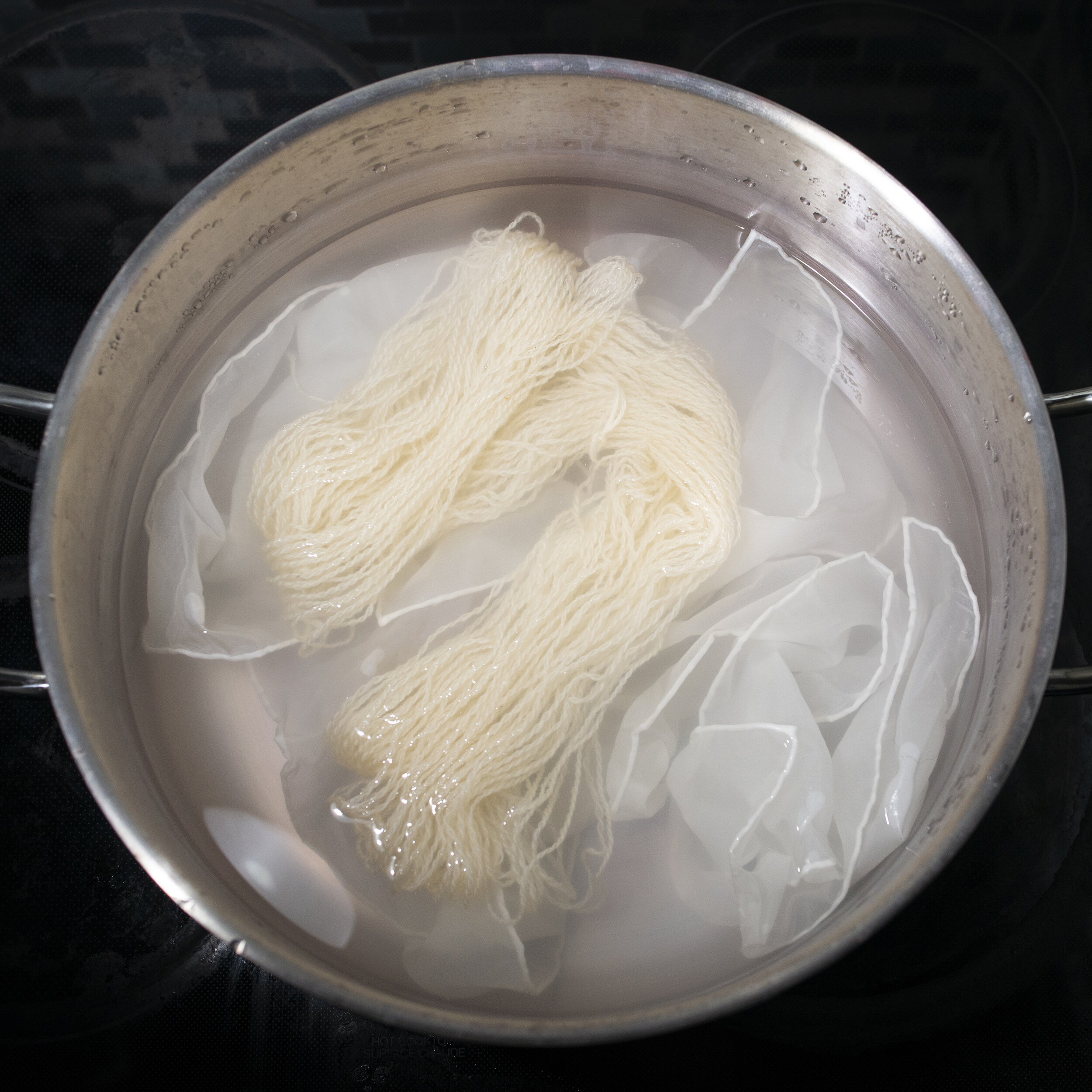

Kusumi Lac Extract gives the best results on mordanted fibers, although it can also be applied to wool and silk without a mordant for softer shades. An alum mordant will produce the classic burgundy and ruby colors. Be sure to weigh your fibers while they are still dry, before you begin scouring, so that you can calculate the correct amount of mordant and dye to be used later. It is also important to make sure the fibers are fully wetted through before they go into the mordant bath, so that the mordant penetrates them deeply and evenly.

For wool: Mordant with 10% WOF alum and 11% WOF cream of tartar.

Weigh out woollen fibers you plan to dye (while they are dry). Multiply that weight by 0.10 to get the amount of alum you will need and by 0.11 to get the correct amount of cream of tartar.

Scour the wool before mordanting. Fill a dye pot with enough warm water for your fibers to move around freely. Add 1 tsp of pH-neutral soap per pound of wool being scoured (we use Synthrapol). Raise the heat to 180F and maintain for an hour. After an hour, turn off the heat and let the wool cool until it is safe to handle. Transfer to a hot rinsing bath and rinse in one or two changes of water until all soap suds are rinsed out.

Fill your dye pot with enough hot tap water for your fibers to move around freely.

Weigh out the correct amount of cream of tartar and pour it into the pot. Mix well until dissolved.

Weigh out the correct amount of alum and pour it into the dye pot. Mix well until dissolved.

Gently place your woolen fibers into the mordanting solution.

Gradually heat the mordant bath to 200F, cover, and maintain the heat for 1 hour. Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye may take better in some places than others.

After an hour, remove from heat and let cool until safe enough to handle.

When ready to rinse, transfer the woolen fibers to a hot rinsing bath (without any soap). Rinse well in one or two changes of hot water to remove excess mordant and cream of tartar.

Dispose of the mordant solution according to local guidelines.

For silk: Mordant at 12% WOF with alum or aluminum lactate.

Weigh out the silk fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of aluminum lactate you will need.

Scour the silk before mordanting. Fill a dye pot with enough warm water for your fibers to move around freely. Add 1 tsp of pH-neutral soap per pound of silk being scoured (we use Synthrapol). Raise the heat to 160F and maintain for an hour. After an hour, turn off the heat and let the silk cool until it is safe to handle. Transfer to a hot rinsing bath and rinse in one or two changes of water until all soap suds are rinsed out.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of aluminum lactate and pour it into the dye pot. Mix well until it has dissolved [Note: You can use an equal quantity of standard alum in place of the aluminum lactate, but aluminum lactate gives the best results].

Gently place your fibers into the mordanting solution.

Heat mordant bath to 160F and maintain heat for 1 hour. Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Steep for 12 hours or overnight in the mordant bath. Move the silk fibers around occasionally to make sure that no resists form (areas like folds or ties where the mordant does not penetrate as well).

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers well in lukewarm water.

For best results, do not allow the mordanted silk to dry out all the way before it is dyed; this may result in an uneven or splotchy dye job.

Dispose of the mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Treat with 20% Sumac Extract and then mordant with aluminum lactate.

Scour cellulose fibers well. Traditionally this is done in an alkaline soda ash solution. Add 1 tsp of soda ash and 1 drop of dish soap to a dye pot full of warm water. Add cellulose fibers and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Tan the cotton: fill your dye pot with just enough hot water for the fibers to move around freely and dissolve 20% WOF Sumac Extract into the water. Add your scoured cotton, raise the temperature to 200F, and maintain for one hour. Remove from heat and allow to cool for at least 3 hours. For best results, steep overnight. This process will make the cotton or linen more receptive to mordants. Afterwards, gently wring out the cotton (just enough so it does not drip everywhere) but do not rinse it, as doing so could wash out some of the tannins that are soaked into the fibers.

Hang the tanned cotton up somewhere and let it dry completely. This will help fix the tannins to the fiber before mordanting. However, be careful to hang it up in such a way that there are no folds in it — otherwise you may get an uneven dye job.

Mordant with aluminum lactate: Fill a dye pot with just enough lukewarm water for your fibers to move around freely. Measure out 20% WOF of aluminum lactate, add to the pot, and stir well until dissolved. Place the tanned cotton in the mordant solution and let it steep for at least three hours and preferably overnight, stirring occasionally to make sure the fibers mordant evenly. It is not necessary to heat the mordant solution. When you are ready to begin dyeing, remove the cotton fibers and wring out gently (while wearing rubber gloves).

Rinse the cotton well in lukewarm water. The cotton is now ready to dye.

Dispose of the mordant solution according to local guidelines.

The Recipes

5. Recipe: Burgundy on Woolens

Kusumi Lac Extract produces a series of very fine, saturated red colors on woolen fibers mordanted with alum. Dyeing at neutral or close to neutral pH, without the addition of any extra acid, will tend to produce a bluer shade of red with hints of burgundy or red wine. Note that just like cochineal, Kusumi Lac Extract does not perform well in hard water; if you know that your water is hard, or if you are not getting the expected depth of color when following this recipe, you can try using bottled spring water or drinking water to build the dye bath instead.

Fill your dye pot with enough warm water for your fibers to move around freely.

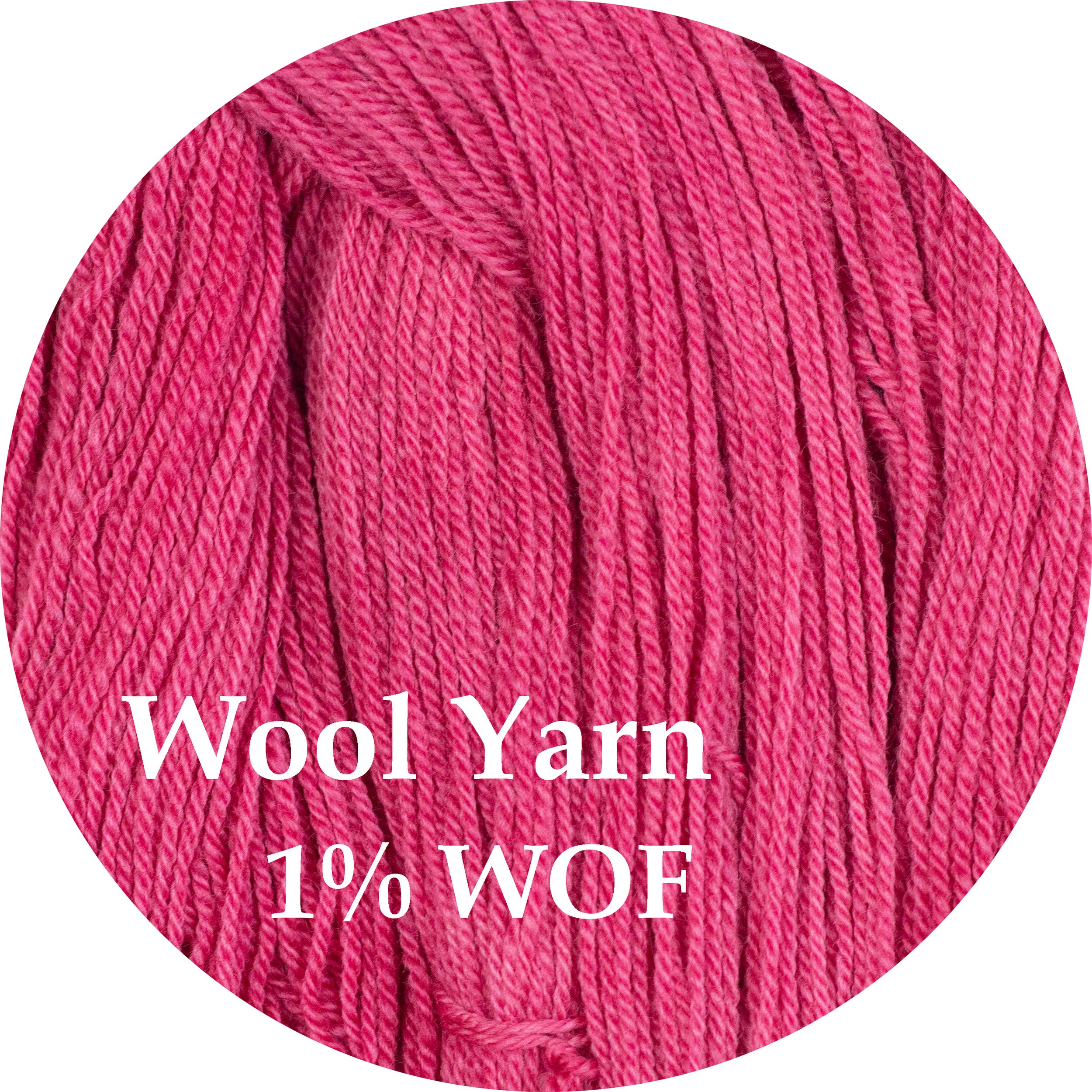

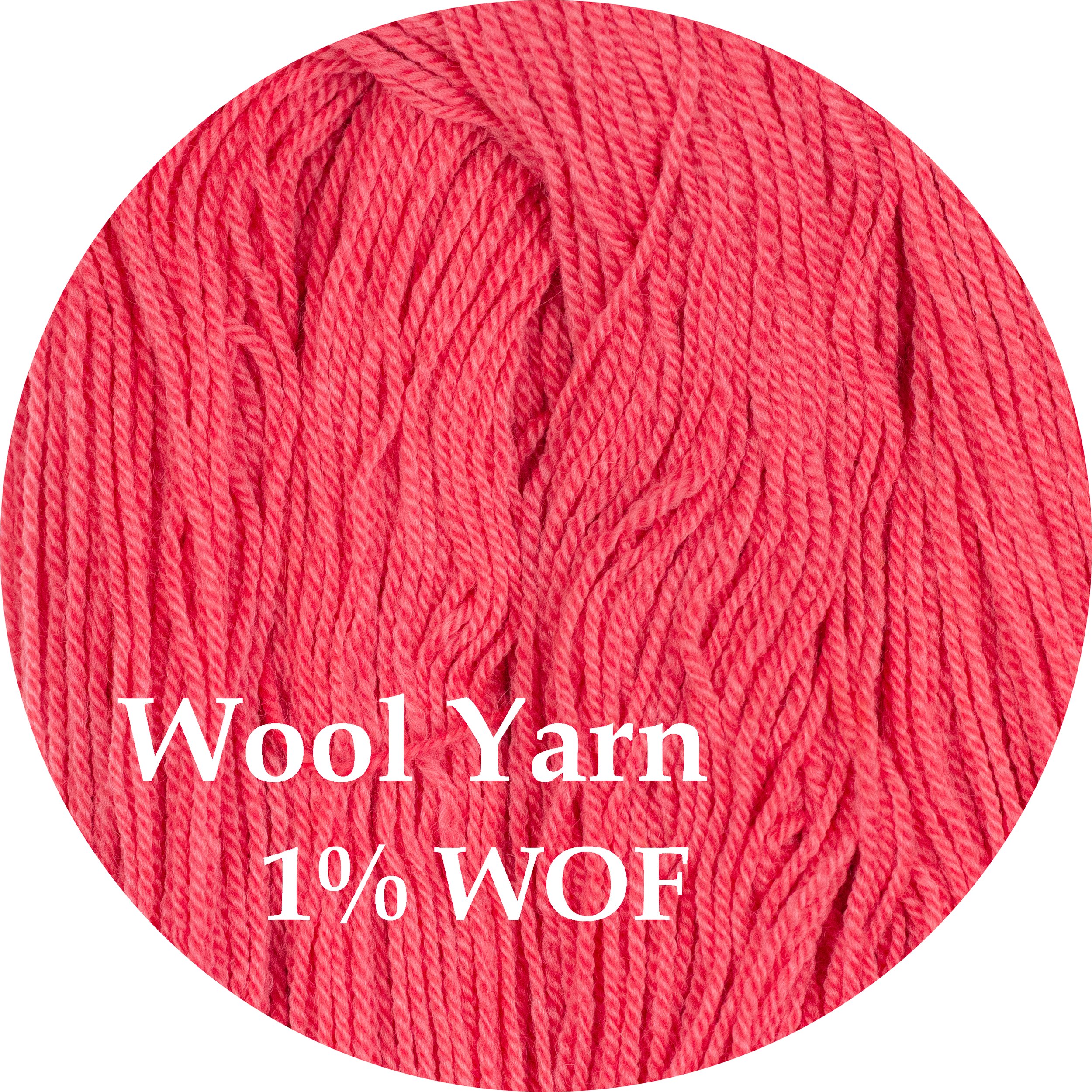

Weigh out the appropriate weight-of-fabric (WOF) of Kusumi Lac Extract powder. Use 1% for a strawberry pink or 4% for burgundy red. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn a dark red shade.

Add your wetted, alum-mordanted wool to the dye bath.

Heat the dyebath to 200F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol)[see note]. Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*NOTE: Kusumi Lac Extract is pH-sensitive, and strong alkalis like washing soda can shift the color of the dyed fibers toward the purplish end of the red spectrum. Many household laundry detergents are strongly alkaline, so they should be avoided if you want to maintain the same hue of red.

6. Recipe: Ruby on Woolens

Acidifying the dye bath with cream of tartar will intensify the color of Kusumi Lac Extract, and the natural red wine hues will shift toward brighter pinks and crimsons. Note that the dye will start to bond to mordanted wool remarkably quickly when the dye bath is acidified, so it is important to raise the heat very gradually and stir the fibers regularly in order to get an even dye job.

Fill your dye pot with enough warm water for your fibers to move around freely.

Acidify the dye bath by adding 1 gram of cream of tartar per gallon of water in the bath. Mix well until fully dissolved [note that if your water source is exceptionally alkaline you may need to add a bit more cream of tartar to get the pH down around 4].

Weigh out the appropriate weight-of-fabric (WOF) of Kusumi Lac Extract powder. Use 1% for a candy pink or 4% for ruby red. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn an orangeish red shade.

Add your wetted, alum-mordanted wool to the dye bath.

Let the wool fibers steep in the dye bath for 10 or 15 minutes before turning on the heat. Stir the fibers regularly. Kusumi Lac Extract will start bonding to woolen fibers very quickly once the heat is turned on, so letting them steep first will help the dye penetrate fully and evenly.

Turn on the heat and heat the dyebath to 200F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol)*[see note]. Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

7. Recipe: Simple Scarlet on Woolens

This easy method of dyeing with lac is mentioned in passing by Frederick Crace-Calvert in his 1878 book “Dyeing and Calico Printing” (p.225). It is essentially a simplified version of cochineal scarlet (minus the hazardous oxalic acid that would be used in a true scarlet recipe). The tin mordant shifts the color of lac dye toward scarlet (a yellower red) in contrast to the crimson shades that develop with alum. This recipe does not require any pre-mordanting since the mordanting and dyeing are done in a single bath. However, be sure the wool is scoured very well before beginning.

Prepare your woolen fibers by scouring them very well, but do not mordant them. They should be clean and thoroughly wetted before beginning.

Fill your dye pot with enough lukewarm (but not hot!) water for your fibers to move around freely.

Acidify the dye bath by adding 2 grams of cream of tartar per gallon of water in the bath* [see Note 1]. Mix well until fully dissolved.

Weigh out the appropriate weight-of-fabric (WOF) of Kusumi Lac Extract powder. Use 1% for pink or 3% for a light scarlet. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn an orangeish red shade.

Weigh out 2% weight-of-fabric (WOF) of tin mordant (stannous chloride)* [see Note 2]. Add to the the dye bath and mix well until dissolved. The dye bath will immediately turn an opaque dark purplish-red.

Gently place your scoured (but unmordanted) woolen fibers into the dye bath.

Let the wool fibers steep in the dye bath for 30 minutes before turning on the heat. Stir the fibers a few times while waiting. This will help the dye and mordant to penetrate the fibers fully and evenly before heat causes them to start to bond with each other.

Turn on the heat and heat the dyebath to a boil very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. When the dye bath just reaches a boil, immediately lower the heat, cover the pot, and maintain the temperature at around 200F for 1 hour. Uncover and stir the fibers occasionally so they dye evenly. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*Note 1: Single-bath recipes such as this one work best in a strongly acidified dye bath, which is why so much cream of tartar is used. The extra acid helps to keep the dye and mordant in solution during the dyeing process; otherwise they would tend to bond to each other (rather than the wool) and form little particles of pigment in the dye bath. Cream of tartar is adequate in this instance, but for deeper scarlets a much stronger acid (oxalic acid) is required.

*Note 2: Exercise caution when using tin mordant. Stannous chloride crystals are caustic and can serious burns if they come in contact with the skin, eyes, and mucus membranes. Wear gloves, a mask, and eye protection when handling stannous chloride powder and tin mordant baths. Be sure to read your manufacturer’s SDS (Safety Data Sheet) before using stannous chloride powder, and follow all recommended safety precautions.

8. Recipe: True Scarlet on Woolens

This method of dyeing scarlet was first discovered in the 17th century when dyers were experimenting with cochineal, but it works equally well with lac dye. The wool is dyed in a single bath with tin and oxalic acid to create a very bright, intense scarlet; many professional dyers considered this to be one of the finest colors achievable with natural dyes. However, both tin mordant and oxalic acid are hazardous chemicals that should be employed with caution. Do not attempt this recipe unless you have an outdoor dyeing setup to dissipate fumes, as well as full protective gear including gloves, goggles, and a respirator mask. Be sure to read the precautionary notes at the bottom of the recipe before beginning.

Prepare your woolen fibers by scouring them very well, but do not mordant them. They should be clean and thoroughly wetted before beginning.

Fill your dye pot with enough cool (not hot!) water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of Kusumi Lac Extract powder. Use 2% for a salmon shade or 5% for a true scarlet. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn an orangeish red shade.

Weigh out 6% weight-of-fabric (WOF) of oxalic acid* [see Note 1]. Add to the dye bath and mix until fully dissolved. The dye bath should turn a bit brighter and orangier.

Weigh out 5% weight-of-fabric (WOF) of tin mordant (stannous chloride)* [see Note 2]. Add to the the dye bath and mix well until dissolved. The dye bath will immediately turn an opaque dark purplish-red.

Gently place your scoured (but unmordanted) woolen fibers into the dye bath.

Let the wool fibers steep in the dye bath for 30 minutes before turning on the heat. Stir the fibers a few times while waiting. This will help the dye and mordant to penetrate the fibers fully and evenly before heat causes them to start to bond with each other.

Turn on the heat and heat the dyebath to a boil very gradually, over the course of at least 30 minutes, stirring regularly so that the wool dyes evenly. When the dye bath just reaches a boil, immediately lower the heat, cover the pot, and maintain the temperature at around 200F for 1 and a half hours. Uncover and stir the fibers occasionally so they dye evenly; avoid inhaling any fumes. After 1 and a half hours, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*Note 1: Oxalic acid is one of the strongest organic acids, and it is required in this recipe in order to keep the large quantities of tin and lac-dye from bonding to each other prematurely and forming little particles of pigment. Oxalic acid can cause serious burns if it touches the eyes, skin, or mucous membranes, and oxalic acid fumes should not be inhaled. Only attempt this recipe if you have an outdoor dyeing setup and full protective gear (gloves, goggles, and respirator mask). Read your manufacturer’s SDS before beginning and observe all recommended safety protocols. If you follow this recipe you agree that Shepherd Textiles LLC is not responsible for any adverse consequences of dyeing with oxalic acid or stannous chloride.

*Note 2: Exercise caution when using tin mordant. Stannous chloride crystals are caustic and can serious burns if they come in contact with the skin, eyes, and mucus membranes. Wear gloves, a mask, and eye protection when handling stannous chloride powder and tin mordant baths. Be sure to read your manufacturer’s SDS (Safety Data Sheet) before using stannous chloride powder, and follow all recommended safety precautions.

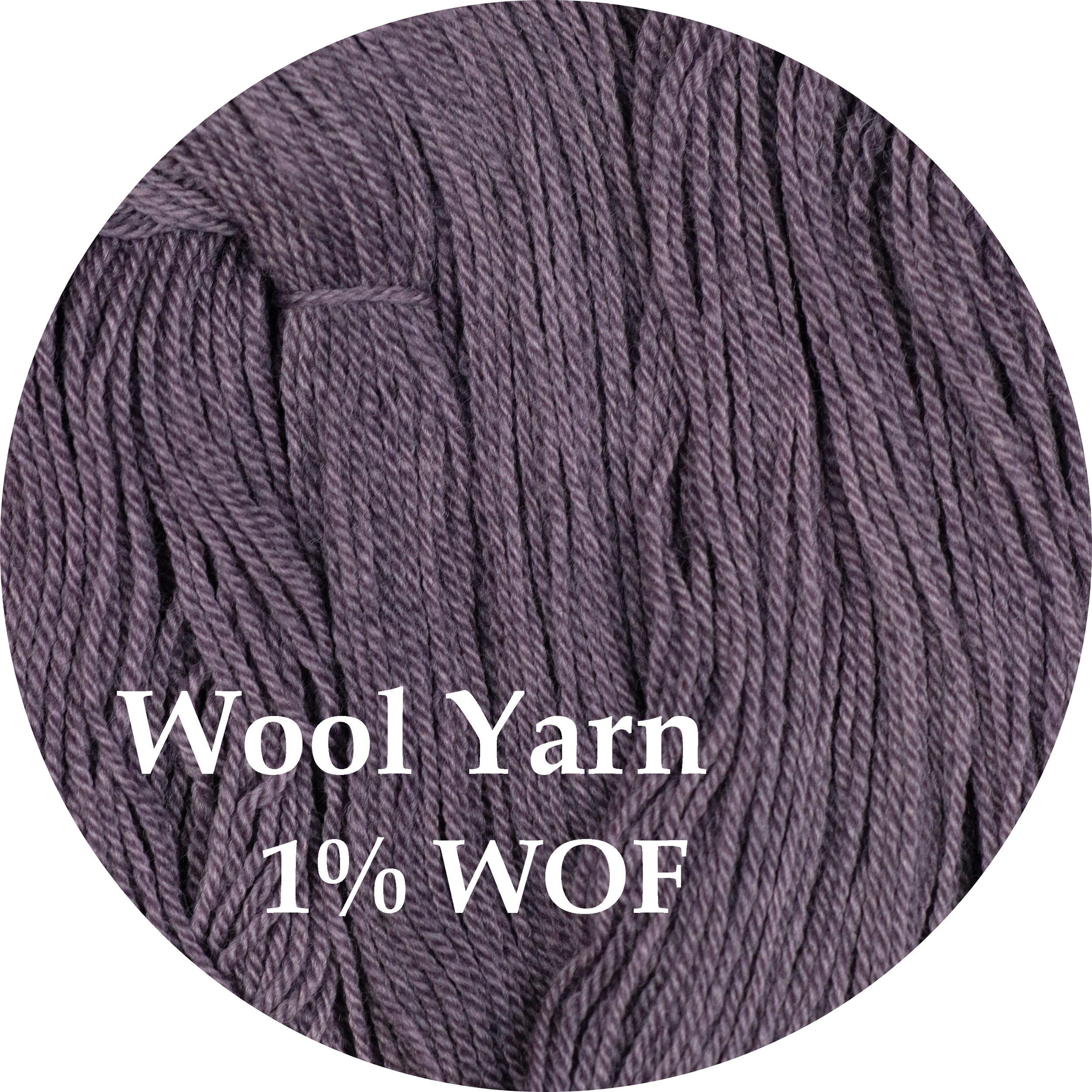

9. Recipe: Eggplant on Woolens

Like most natural red dyes, Kusumi Lac Extract will shift toward purple when combined with an iron mordant. We generally prefer to pre-mordant wool with iron, rather than saddening the wool with iron after dyeing it. The reason is that when wool is premordanted with iron and plenty of cream of tartar, the cream of tartar will help protect the “handle” or softness of the wool, which can otherwise be damaged by the iron. Using lots of cream of tartar also prevents the wool from picking up any brown color from the iron.

Prepare your woolen fibers by mordanting them with iron rather than alum. Follow the directions in Section 4 for mordanting wool, but use 8% ferrous sulfate and 20% cream of tartar. The large amount of cream of tartar is necessary to prevent the woolen fibers from picking up a brown hue from the iron mordant. After mordanting, rinse the fibers well in hot water and then proceed to dyeing.

Fill your dye pot with enough warm water for your fibers to move around freely.

Acidify the dye bath by adding 1 gram of cream of tartar per gallon of water in the bath. Mix well until fully dissolved [note that if your water source is exceptionally alkaline you may need to add a bit more cream of tartar to get the pH down around 4].

Weigh out the appropriate weight-of-fabric (WOF) of Kusumi Lac Extract powder. Use 1% for lilac or 3% for eggplant purple. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn an orangeish red shade.

Add your wetted, iron-mordanted wool to the dye bath.

Let the wool fibers steep in the dye bath for 10 or 15 minutes before turning on the heat. Stir the fibers regularly. Kusumi Lac Extract will start bonding to woolen fibers very quickly once the heat is turned on, so letting them steep first will help the dye penetrate fully and evenly.

Turn on the heat and heat the dyebath to 200F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol)*[see note]. Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

10. Ruby on Silk

Kusumi Lac Extract gives excellent results on silken fibers, and in fact we think it might even be the best natural red on silk. The quantity of dye necessary for a deep shade will depend on the weight of the silk; very thin silks like satin and habotai will need a greater amount (calculated in terms of weight-of-fabric) to achieve the same depth of color. Note that the dye bath should be acidified with cream of tartar for the best results; dyeing at neutral pH will tend to produce more muted pink and strawberry shades.

Fill your dye pot with enough warm water for your fibers to move around freely.

Acidify the dye bath by adding 1 gram of cream of tartar per gallon of water in the bath. Mix well until fully dissolved [note that if your water source is exceptionally alkaline you may need to add a bit more cream of tartar to get the pH down around 4].

Weigh out the appropriate weight-of-fabric (WOF) of Kusumi Lac Extract powder. Use 4% for thicker weights of silk, or up to 8% for thin silks like satin and habotai. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn an orangeish red shade.

Add your wetted, alum-mordanted silk to the dye bath.

Heat the dyebath to 180F very gradually, over the course of about 30 minutes, stirring regularly so that the silk dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the silk is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of silk (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

11. Recipe: Simple Scarlet on Silk

The same method that is used for dyeing wool a soft shade of scarlet (see Section 7) also works with silk. The tin mordant shifts the color toward a bright salmon shade of red. This recipe does not require any pre-mordanting since the mordanting and dyeing are done in a single bath. However, be sure the silk is scoured very well before beginning. Single-bath dyeing methods are fairly unforgiving of poorly scoured fibers, and any dirt or grease will show up as obvious lighter or darker spots on the dyed fibers.

Prepare your silk fibers by scouring them very well, but do not mordant them. They should be clean and thoroughly wetted before beginning.

Fill your dye pot with enough lukewarm (but not hot!) water for your fibers to move around freely.

Acidify the dye bath by adding 2 grams of cream of tartar per gallon of water in the bath. Mix well until fully dissolved.

Weigh out the appropriate weight-of-fabric (WOF) of Kusumi Lac Extract powder. Use 4% for thicker weights of silk or 8% for very thin silks like satin and habotai. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn an orangeish red shade.

Weigh out 2% weight-of-fabric (WOF) of tin mordant (stannous chloride)* [see Note 1]. Add to the the dye bath and mix well until dissolved. The dye bath will immediately turn an opaque dark purplish-red.

Gently place your scoured (but unmordanted) silk fibers into the dye bath.

Let the silk steep in the dye bath for 30 minutes before turning on the heat. Stir the fibers a few times while waiting. This will help the dye and mordant to penetrate the fibers fully and evenly before heat causes them to start to bond with each other.

Turn on the heat and heat the dyebath to a boil very gradually, over the course of about 30 minutes, stirring regularly so that the silk dyes evenly. When the dye bath reaches 200F, immediately lower the heat, cover the pot, and maintain the temperature at around 180F for 1 hour. Uncover and stir the fibers occasionally so they dye evenly. After 1 hour, turn off the heat and allow to cool.

When the silk is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of silk (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*Note 1: Exercise caution when using tin mordant. Stannous chloride crystals are caustic and can serious burns if they come in contact with the skin, eyes, and mucus membranes. Wear gloves, a mask, and eye protection when handling stannous chloride powder and tin mordant baths. Be sure to read your manufacturer’s SDS (Safety Data Sheet) before using stannous chloride powder, and follow all recommended safety precautions.

12. Eggplant on Silk

After dyeing silk red, the silk can be “saddened” with iron to produce a warm eggplant purple. The silk can be saddened either immediately after dyeing it red, or later on after the silk has been rinsed and dried. If you sadden it later, however, be sure to wet the silk thoroughly before you begin so it shifts color evenly.

Prepare your silk by mordanting it with alum and dyeing it red using the recipe for “Ruby on Silk” (Section 10).

After the silk is dyed red, you can either sadden it immediately, or sadden it later after it is rinsed and dried. If saddening immediately, prepare the saddening bath (Step 3) as soon as the silk is finished dyeing; transfer the silk directly from the dye bath into the saddening bath (although take a minute to let as much extra dye bath liquid as possible drip back into the dye pot). If saddening later after the silk has been rinsed and dried, prepare it by soaking it in lukewarm water until it is thoroughly wetted through.

Prepare a saddening bath. Fill a dye pot with enough warm water for your fibers to move around freely. Weigh out 3% weight-of-fabric (WOF) of iron powder (ferrous sulfate). Add to the saddening bath and mix well until fully dissolved.

Add your wetted silk to the saddening bath.

Heat the saddening bath to 180F very gradually, over the course of about 30 minutes, stirring regularly so that the silk saddens evenly. Maintain this heat for 30 minutes and continue to stir occasionally. After 30 minutes, turn off the heat and allow to cool.

When the silk is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of silk (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

13. Fuchsia on Cotton

Kusumi Lac Extract produces soft but pleasant shades of fuchsia on cotton. One of the challenges of applying lac (and also cochineal, a similar dyestuff) to plant fibers is that lac dyes best in an acidic dye bath, but cotton fibers do not bond to dyes very well in an acidic environment. Success applying lac to plant fibers will depend very much on the thoroughness of the mordanting.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 4% weight-of-fabric (WOF) of Kusumi Lac Extract powder. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn a dark red shade.

Add your wetted, alum-mordanted cotton to the dye bath.

Heat the dyebath to 200F very gradually, over the course of about 30 minutes, stirring regularly so that the cotton dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally* [see note]. After 1 hour, turn off the heat and allow to cool.

When the cotton is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of cotton (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Kusumi Lac Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.