Logwood Shavings

A Guide to Logwood

Shepherd Textiles Logwood Natural Dye contains the chipped and shaved heartwood of haemotoxylin campechianum, the Campeche Logwood tree. Logwood contains a purple pigment called hematein which has a very strong affinity for natural fibers; it gives rich, saturated shades without too much difficulty. Logwood is most famous for the beautiful royal purples that it produces on fibers mordanted with alum, but the color changes dramatically with different mordants. Paired with copper it gives steely dark blues, and with iron it gives greys and blacks. Our logwood shavings are very potent, and will produce dark purples and midnight blues using just 25% weight-of-fabric on well-mordanted fiber.

1. Background on Logwood

The logwood tree, haemotoxylin campechianum, is native to southern Mexico and the Yucatan peninsula. Its use as a dye was well-known to the prehispanic Maya, and Spanish explorers began trading for it as early as 1502. Logwood quickly became one of the major exports of New Spain, along with silver and cochineal, because for several centuries it was the only reasonable source of purple and black dye. Contemporary sources describe Spanish galleons crossing the Atlantic with the decks piled high with logwood timber, and logwood ships were one of the major targets of English pirates along the Spanish Main (Ortiz-Hidalgo and Pina-Oviedo 2019:4). The port of Campeche on Mexico’s Gulf Coast controlled most of the logwood trade in the 17th and 18th centuries, hence why logwood is sometimes referred to as Campeachy Wood. The botanical name, haemotoxylin, is Greek for blood-tree, referring to the dark color of the heartwood after it oxidizes.

The heartwood of the logwood tree contains a potent compound called haemotoxylin. After it is extracted by boiling (or, today, by steam extraction) it is exposed to air and oxidizes into the pure dyestuff called hematine. Hematine is a powerful dye on all natural fibers, even cellulose fibers like cotton that are often resistant to natural dyes. However, it requires a mordant to bond effectively to fiber. Alum gives rich purples, although they have a reputation for fading in sunlight. Copper yields blues that Victorian dyeing houses celebrated for their strength and lightfastness. Iron gives grays and true black. Logwood was mostly abandoned after aniline black dye was invented in 1865, but it is still used today to safely dye medical sutures black so they can be seen more easily.

Nature’s Most Beautiful Purple

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust. Work in a well-ventilated space, and avoid inhaling sawdust. Wear a mask if necessary while working with fine powders.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Logwood shavings, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Prop 65 Warning: This product may expose you to wood dust, which is known to the state of California to cause cancer.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Fine mesh strainer. For straining out the wood after extraction.

Pickling lime/cal (Optional). A very tiny amount, around 0.5% WOF, can shift the color from warmer purples to cooler purples.

4. Preparation: Scouring and Mordanting

Logwood only bonds effectively to fibers that are mordanted, and different mordants will dramatically change the color that it produces. For royal purples, use alum; for navy blues, use copper; and for grays and blacks, use iron. Logwood is an excellent dye for both animal fibers and plant fibers like cotton, but the cotton will need to be well-tanned and mordanted first. If possible, let the fibers soak in water for a few hours before mordanting, so the mordant penetrates them deeply and evenly. Be sure to weigh the fibers first, while they are still dry, so you can calculate the correct amount of mordant.

For wool fibers (wool, alpaca, etc.): Mordant with 10% alum and 11% cream of tartar.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.10 to calculate the amount of alum you will need, and 0.11 to calculate the amount of cream of tartar.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of cream of tartar and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Next, weight out the correct amount of alum and add it to the dye pot. Mix until well dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180°F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180°F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. Otherwise, an uneven dye job may result.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results when dyeing thick yarn or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers well in lukewarm water. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For silk: Mordant with 15% alum.

Follow the directions for mordanting wool described above. However, use 15% alum and omit the cream of tartar.

For cellulose fibers (cotton, linen, etc.): Treat with a tannin before mordanting.

Logwood gives excellent results on cotton, but the cotton should be properly tanned and mordanted before dyeing.

Scour (clean) the cotton by adding 1 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with just enough hot water for your fibers to move around freely - the more concentrated the tannin bath, the stronger the results will be. Dissolve 20% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they can bond to the mordant. For the very strongest results, hang the cotton up and let it dry before proceeding to mordanting.

Prepare an alum mordant bath using either (a) 20% weight-of-fabric alum + 5% soda ash (washing soda), or (b) 20% weight-of-fabric of aluminum lactate. Either option will create a relatively neutral pH mordant bath that bonds well with cotton.

Heat the mordant bath to 150°F or 160°F, place the cotton in it, and raise the heat to 190°F. Maintain for one hour, stirring occcasionally to make sure the fibers mordant evenly. After one hour, remove from heat. When cool enough to handle safely, remove fibers and rinse well in lukewarm water.

5. Preparation: Building the Dye Bath

Building a dye bath with logwood shavings is very easy, but the wood will need to soak overnight for best results. If possible, plan ahead to start the process the day before you start dyeing.

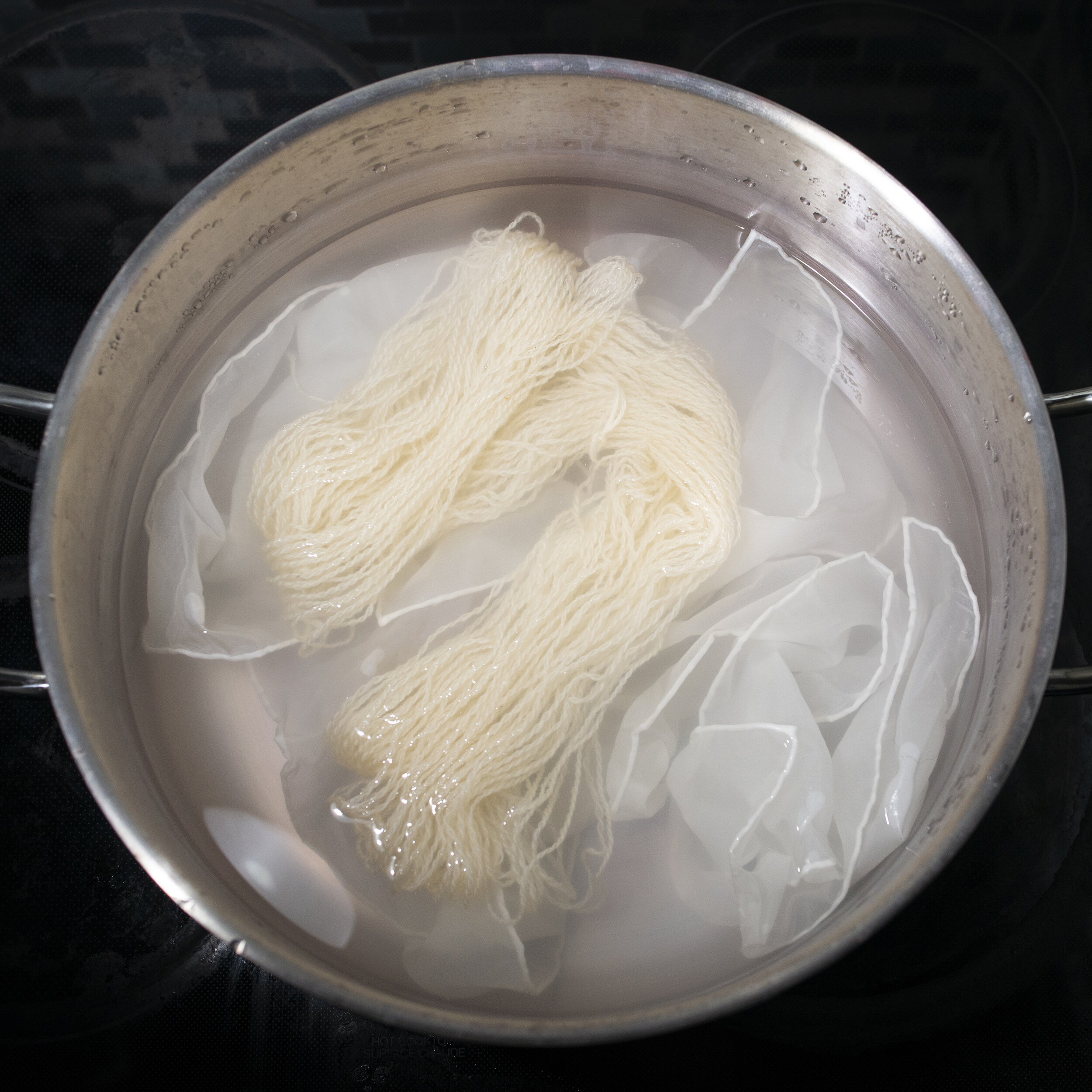

Step 2. The water will begin to turn a pink-purple color almost as soon as it touches the wood shavings.

Step 5. Filter the extraction liquid through cheesecloth or a fine mesh strainer to get out any wood bits.

Weigh out the quantity of logwood shavings called for in your recipe—usually around 20% to 25% weight-of-fabric for darker shades.

Put the logwood in your dye pot and fill it about 2/3 full with lukewarm water. The water should immediately start to turn a clear pink-purple color. However, do not apply heat yet—the wood just needs to soak so the water can penetrate it fully*.

Leave to soak overnight.

The next day, raise the temperature of the dye bath to 200F—just a bit below a boil—and hold for 2 hours. The water in the bath should turn a very dark purple. Take off the heat and allow to cool to room temperature.

Filter the purple dyebath liquid into a holding container, like a plastic bucket or a second dye pot. Strain it through a cheesecloth, an old t-shirt, or a very fine mesh sieve; any wood that makes it into the final dyebath will cause splotches on your fabric.

Return the strained wood to the dye pot and cover with a few inches of hot water. Simmer this for another 20 minutes or so to extract the rest of the dyestuff. Let cool, then strain it and combine it with the first extraction liquid.

Dispose of the wood and clean out your dye pot. Pour the combined extractions back into it. This dark purple liquid will be your dye bath.

*Logwood decoctions tend to lose their color and fade when left standing; they are strongest immediately after extraction. For that reason, we recommend waiting until the second day to apply heat to the extraction bath.

The Recipes

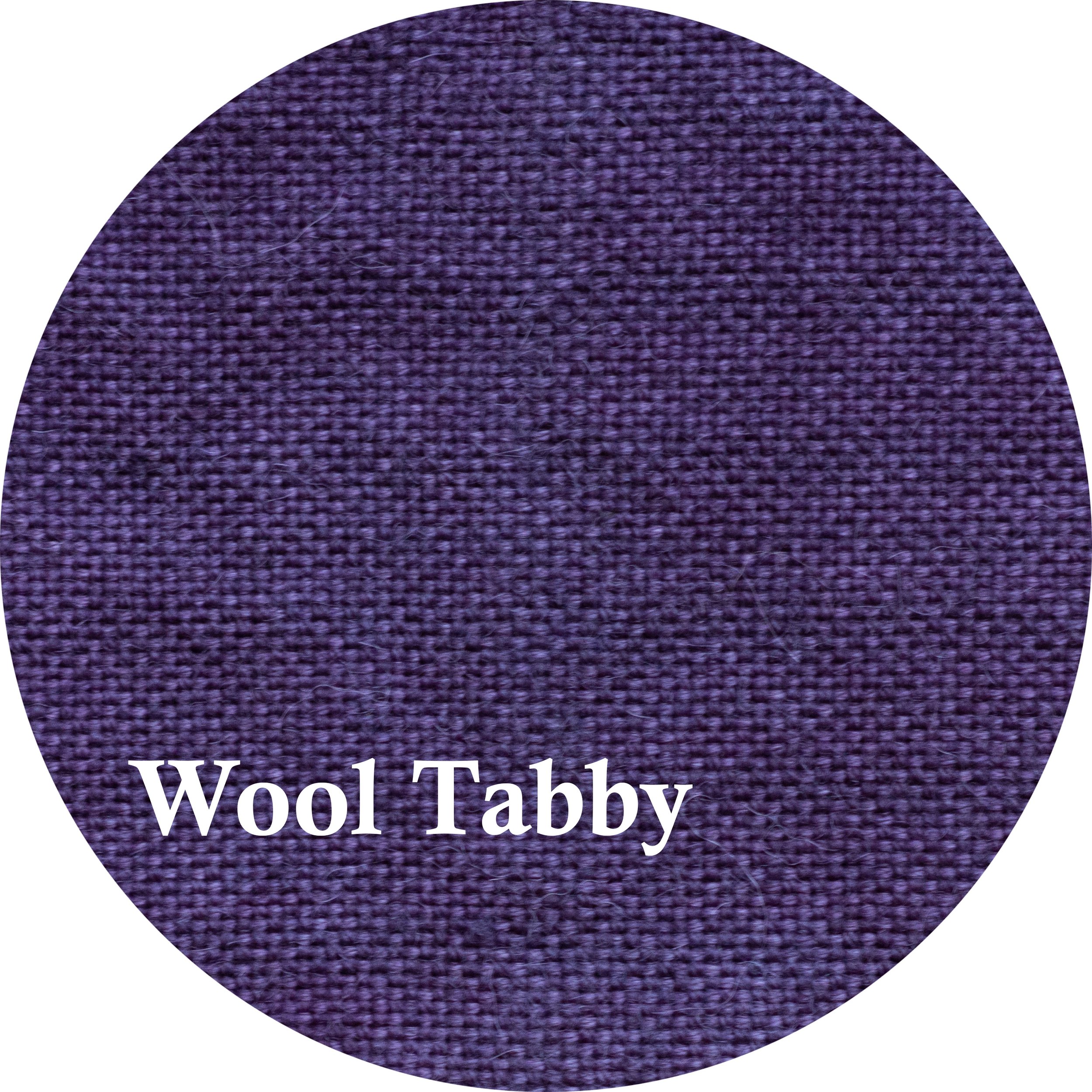

6. Recipe: Royal Purple

Logwood is most famous for the beautiful royal purple that it dyes on an alum mordant. Logwood has an exceptional affinity for most natural fibers, and your fabric will probably begin to turn purple the moment it enters the bath. Indeed, softer shades of lavender can be applied to wool and silk without heat by simply soaking the fibers in the bath until the desired shade has developed. Our logwood shavings are strong enough to give deep purples at 25% weight-of-fabric—for lighter shades, use half as much wood.

Build the dyebath, as described in Section 5. Use 25% weight-of-fabric (WOF) of logwood shavings.

[Optional] If you would prefer a slightly cooler purple versus a warmer purple, add 0.5% weight-of-fabric of calcium hydroxide (pickling lime or cal) to the dye bath right before putting the fibers in. For best results, weigh out the cal, put it in a disposable cup with half a cup of warm water, and let it sit for 10 minutes to settle. Then, carefully pour off the cloudy liquid into the dye bath while leaving the big particles of white calcium in the bottom of the cup. This will shift the color of the bath toward bluer shades, but use carefully—alkalis break down the dyestuff in logwood, and if the dyebath becomes too alkaline the resulting colors may turn out muddied.

When the dyebath is ready, add your alum-mordanted, wetted fibers.

Raise the temperature to 160°F, then maintain for 30 minutes. Stir occasionally to make sure everything dyes evenly.

After 30 minutes, remove pot from heat and allow to cool to room temperature.

Remove the fibers and rinse briefly in lukewarm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. Logwood purple is extremely sensitive to PH, and using a strongly acidic or alkaline detergent may shift the color in unwanted ways. CAUTION: Logwood will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

7. Recipe: Rainy Morning

Logwood’s color shifts from purple to blue on fiber that has been mordanted with copper. This is not the bright, cheerful blue of indigo, but a more somber slate blue. If indigo blue is a sunny summer sky, logwood blue is a rainy, contemplative morning. This recipe calls for 20% weight-of-fabric of logwood shavings for a medium shade; for very dark, almost midnight blue shades, increase the quantity of wood to 30%. Logwood blue is more lightfast than logwood purple, and it is an excellent choice for all natural fibers including cotton—just make sure the cotton is well-tanned before mordanting with copper.

Before starting, mordant your fibers with copper rather than with alum. Follow the directions for mordanting in Section 4 above. However, for wool, use 5% copper sulfate and 5% cream of tartar. For silk, use 5% copper sulfate. For cotton, tan with Sumac Extract as described and then mordant with 5% copper sulfate (no washing soda is necessary).

Build the dyebath, as described in Section 5. Use 20% weight-of-fabric (WOF) of logwood shavings.

When the dyebath is ready, add your copper-mordanted, wetted fibers.

Raise the temperature to 160°F, then maintain for 30 minutes. Stir occasionally to make sure everything dyes evenly.

After 30 minutes, remove pot from heat and allow to cool to room temperature.

Remove the fibers and rinse briefly in lukewarm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Logwood will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

8. Recipe: Black on Cotton

Logwood produces shades of gray and black on fibers mordanted with iron. Logwood black is strong, lightfast, and deeply saturated. Indeed, many professional dyeing houses in the early 20th century continued to prefer logwood for dyeing cotton black even after synthetic black dyes had become available. Getting a good black on cotton is mostly a matter of proper mordanting; the cotton first has to be “gray-mordanted” by soaking it in Sumac Extract overnight and then working it in an iron bath. Gray-mordanted cotton will then easily dye black in a strong logwood dyebath.

Part 1: Gray-Mordant the Cotton with Sumac and Iron

Fill your dye pot with just enough hot water for your fibers to move around freely - the more concentrated the tannin bath, the stronger the results will be. Dissolve 20% weight-of-fabric of Sumac Extract into the water, stirring well to make sure that any clumps are broken up.

Add the cotton, raise the heat to 180-190F, and maintain for an hour.

Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight.

After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they can bond to the mordant. For the very strongest results, hang the cotton up and let it dry before proceeding to mordanting.

Fill a clean dye pot with enough water for your cotton to move around freely. Dissolve 4% weight-of-fabric iron powder into it and mix well.

Heat the mordant bath to 150°F or 160°F, place the cotton in it, and raise the heat to 190°F. Maintain for thirty minutes, stirring occcasionally to make sure the fibers mordant evenly. After thirty minutes, remove from heat. When cool enough to handle safely, remove fibers and rinse well in lukewarm water.

The rinsed cotton can be dyed immediately, or hung up to dry and used later.

Part 2: Dye the Cotton Black

Build a logwood dyebath as described in Section 5. Use 40% weight-of-fabric (WOF) of logwood shavings.

[Optional] Add 5% weight-of-fabric of Osage Orange shavings when building the dyebath. This will shift the final hue toward more of a neutral black, whereas logwood alone will produce a black with blue undertones when wet or when viewed in indirect light. Instead of Osage Orange you can also use another yellow dye, for example, 1% weight-of-fabric of Old Fustic Extract.

When the dyebath is strained and ready, add the gray-mordanted cotton.

Raise the temperature to 190F and maintain for 25 minutes. Stir occasionally to make sure everything dyes evenly.

After 25 minutes have passed, lift the cotton out of the dyebath with metal tongs and “sadden” the dyebath by adding 2% weight-of-fabric iron powder. Mix well, then return the cotton to the bath and heat for another 5 minutes.

After a total of 30 minutes of dyeing, remove the pot from the heat and allow it to cool to room temperature.

Remove the cotton and rinse well in a bath of lukewarm water and a few drops of PH-neutral detergent. This will help restore the cotton’s hand and luster after all the mordanting and boiling, and it will help fix the dye. CAUTION: Logwood may bleed if not thoroughly rinsed.

Hang up to dry out of direct sunlight.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.