Old Fustic Extract

A Guide to Old Fustic Extract

Shepherd Textiles Old Fustic Extract is made from a tropical mulberry tree called maclura tinctoria. The tree’s heartwood contains a powerful orange-yellow flavonoid dye known as morin. Old Fustic was valued for centuries because of the deep, rich shades it can produce on wool, cotton, and leather. However, over-logging and competition with cheaper synthetic dyes made it obsolete in the early 20th century, and today it is one of the rarest of all the natural dyes. Old Fustic is powerful, easy to work with, and it is also highly tannic, which makes it perfect for dyeing cotton and linen. Use at 5% weight-of-fabric for a vibrant yellow-orange. Product of France. Produced by a GOTS (Global Organic Textile Standard) certified manufacturer.

1. Background on Old Fustic

Dyer’s Mulberry

Old Fustic, maclura tinctoria, is a member of a mulberry genus that is native to the tropical Americas as far south as Argentina. The fruits are reported to be delicious, and in its native range they are eaten as snacks or as a juice. Perhaps more importantly, the heartwood of Old Fustic contains a powerful orange-yellow dye known as morin. Like logwood, Old Fustic became a major export of New Spain in the 17th century, and for several hundred years it was celebrated by European dyers for its rich orange hue (see Mell 1918:823). However, Old Fustic seeds have a very low germination rate of 30% (Gomes et al. 2003:293) which means they reproduce themselves slowly and are extremely vulnerable to over-logging. By the early 20th century, the tree’s populations had been decimated and it fell out of use after World War I. Old Fustic is now a protected species across much of its range, and only limited numbers can be harvested. As a result, Old Fustic is one of the rarest and most expensive of natural dyes.

Shepherd Textiles Old Fustic Extract is made in France from sustainably harvested Central American wood. It is the most powerful Fustic Extract available on the international market, and gives strong colors with just 5% weight-of-fabric. It is an excellent choice for all natural fibers, and it is naturally high in tannins, which makes it an excellent choice for dyeing cellulose fibers like cotton. It also makes a good base for overdyeing with indigo or madder to get greens and oranges.

2. Safety Precautions

DO NOT INGEST. This extract was prepared for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Old Fustic Extract can permanently dye clothing, countertops, rugs, utensils, or other property. Avoid contact with anything that is not meant to be dyed.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Old Fustic Extract, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely. Otherwise, particles of dye may get stuck on the fabric and cause dark splotches.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling extract powder and while handling mordanted/dyed fiber before it is rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and extract powder.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Disposable cup. For mixing the extract powder to a paste.

4. Preparation: Mordanting with Alum

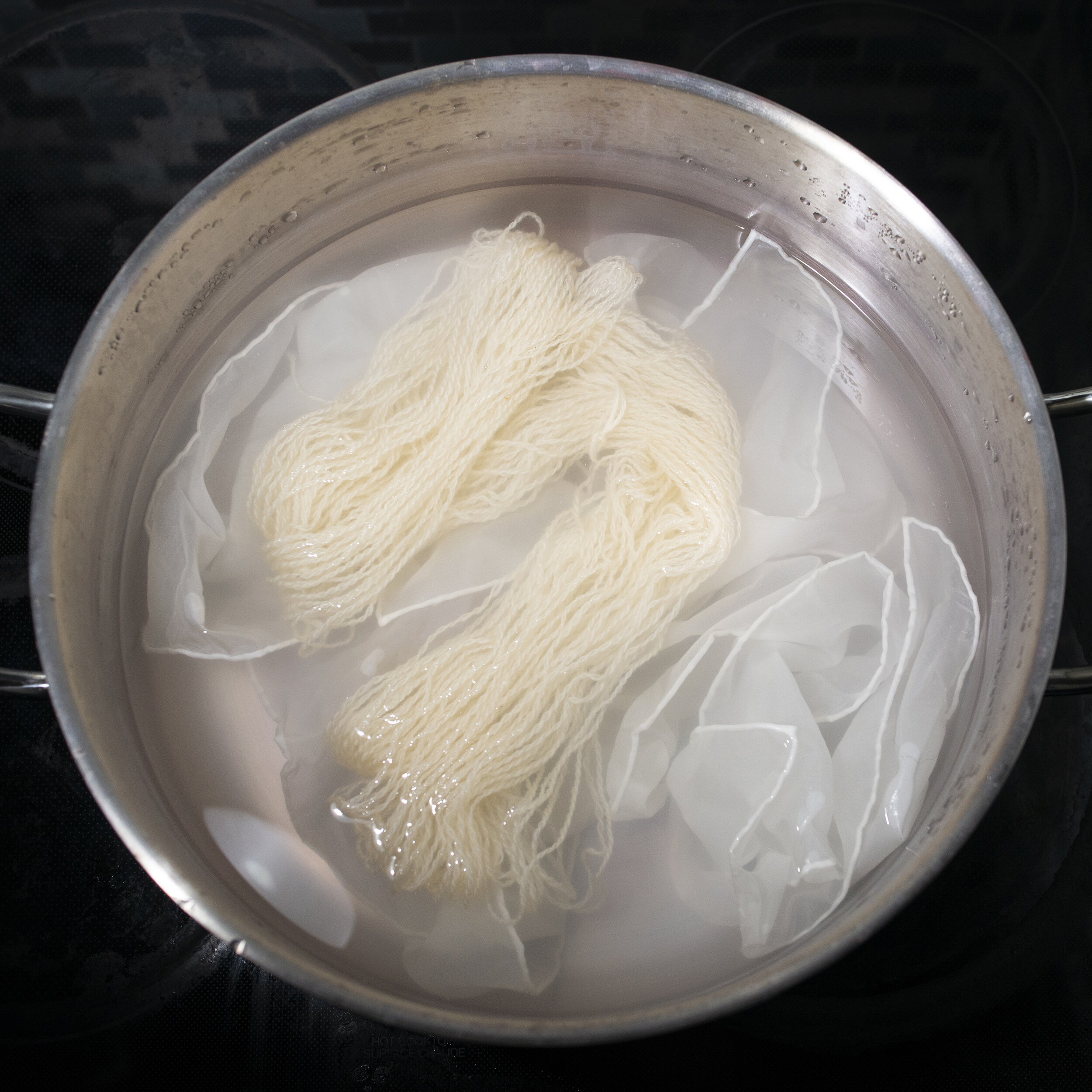

Old Fustic Extract is tannic enough to be used without a mordant, but a mordant will make the colors much deeper and more light-fast. Alum is the standard mordant to use for orange-yellow shades. For best results, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

Alum will dissolve quickly into hot tap water.

Heat fibers for an hour at 180F, then allow to cool.

For protein fibers (wool, silk, alpaca, etc.): Mordant at 12% WOF with alum.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum you will need.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This will improve results, especially when dyeing thick or tightly woven fabrics.

Remove cooled fibers. Wearing rubber gloves, gently squeeze excess mordant solution back into the pot. Rinse briefly in lukewarm water. The fiber does not need to be thoroughly washed, but any excess alum should be rinsed out. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Scour well and [optionally] treat with a tannin before mordanting.

Old Fustic Extract has a good affinity for cellulose fibers, and it can be applied successfully to cotton even without a tannin pre-treatment. However, treating cellulose fibers with a tannin before mordanting will improve mordant penetration, deepen the final color, and make it more colorfast. You can use a clear tannin like Sumac Extract for this purpose, but because Old Fustic Extract is already highly tannic, you can also use it as its own pre-treatment. Essentially, you dye the cotton with Old Fustic, mordant it with alum, then dye it with Old Fustic again. This is not necessary if you are content with a medium shade of color, but it will make it possible to get really dark orange-yellow colors on cotton.

Scour cellulose fibers well. Traditionally this is done in a highly alkaline soda ash solution. Add 2 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add cellulose fibers and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well. Household detergents like Tide© are also alkaline (PH 11), so you can also toss the fiber in a washing machine on a high-temperature cycle with plenty of detergent. This will not clean them nearly as deeply as simmering with soda ash, but it will yield much better results than not scouring at all.

[OPTIONAL] Apply a tannin to the scoured fabric. Sumac Extract is a good choice in general, but you can also use Old Fustic Extract itself. To use, fill your dye pot with hot water, dissolve 5% WOF of the extract into the dye bath, and simmer for an hour. This process will make the cotton or linen more receptive to alum and lay down a base of color. Be sure to keep the fiber moving around: Sumac and Old Fustic generally dissolve well, but some other tannins have insoluble particles that love to get stuck in fabric. If they do, it can cause splotches later on in the dyeing process. After an hour, let cool, remove fibers, and rinse well.

Mordant with alum as described above for protein fibers.

The Recipes

5. Recipe: Fustic Orange

Old Fustic gives a rich, warm, orange-hued yellow when used with an alum mordant. It has a strong affinity for all natural fibers, and usually only needs an hour in the dye bath. Use 5% weight-of-fabric (WOF) for the classic orange-yellow shade. For paler shades, use 2-3% WOF.

Fill your dye pot with warm water, making sure there is enough room for the fabric to move around and for water to circulate freely.

Weigh out 5% weight-of-fabric (WOF) Old Fustic Extract into a disposable cup (multiply the dry weight of the fabric by 0.05 to get the correct amount of extract).

Add a little hot water to the cup and mix to form a thin slurry. Old Fustic Extract has a natural tendency to form little clumps of powder during storage: make sure to break these up, otherwise they may cause splotches on your fiber.

Pour the Old Fustic Extract slurry into the dyebath and mix well. At this point the dyebath will be an intense orange-yellow.

Add your pre-mordanted, wetted fibers to the dyebath.

Raise the temperature to 180°F. Maintain for 1 hour, stirring every 20 minutes or so to make sure everything dyes evenly.

After 1 hour, remove pot from heat and allow to cool to room temperature. You can cover and leave overnight to steep to deepen the color, but be sure there are no solid particles in the dye bath, as these may cause splotches if they come to rest on the fiber.

When finished dyeing, remove the fibers and rinse briefly in lukewarm water to remove any particles of dye. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For final rinsing, we recommend using a PH-neutral detergent like Synthrapol, which is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Old Fustic Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

NOTE: There are conflicting reports in the scientific literature regarding the light-fastness of Old Fustic. One oft-cited experimental study from the 1980s (Crews 1982:48) concluded that it is very susceptible to fading, whereas more recent studies have concluded that the color of morin-based natural dyes actually deepens with sun exposure (e.g., Doty, Haar, and Kim 2016:8). Indeed, our manufacturer in France gives Old Fustic their highest light-fastness rating, comparable only to indigo. It may be that the earlier studies used inferior dye material or poor mordanting technique. We have kept swatches of Fustic-dyed fabric (wool, silk, and cotton) near an east-facing window for several months and have not noticed any loss of color, but you may want to store dyed items out of direct sunlight if you are concerned about fading.

6. Recipe: Olive Green

Iron shifts the color of Old Fustic Extract toward a rich olive green. Iron can be applied as an afterwash, by first dyeing the fibers yellow and then heating them in a solution of 2% weight-of-fabric iron sulfate until the color has shifted. However, for the strongest and most lightfast tones, apply Old Fustic Extract to fibers pre-mordanted with iron rather than alum. Pre-mordanting with iron is not recommended for soft wool like merino, as it can coarsen and damage the fibers. However, mordanting with iron works well with silk and wool yarns with a heavy twist, like rug warp.

Follow the recipe for “Fustic Orange” However, instead of using fiber mordanted with alum, use fiber mordanted with iron. To mordant with iron, follow the directions for mordanting in Section 4. However, replace the 12% alum with 2% iron (ferrous sulfate). Heat the mordant bath to 180F for 30 minutes rather than an hour, and do not let the fibers steep overnight—remove them from the mordant bath as soon as they are cool enough to handle. Wearing rubber gloves, rinse the fibers well in lukewarm water to remove any excess mordant, as unbonded iron can corrode fiber.

CAUTION: Iron powder is an irritant and may be harmful if ingested, especially for children and pets. Please read your vendor’s safety sheet (MSDS) before using iron as a mordant. Wear gloves, a mask, and eye protection when handling iron powder, iron mordant baths, and iron-mordanted fibers that are not fully rinsed. Keep iron powder and iron mordant baths out of reach of children and pets. Dispose of the mordant bath according to local regulations.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without permission and attribution.