Pomegranate Extract

A Guide to Pomegranate Extract

Shepherd Textiles Pomegranate Extract natural dye is made from the rinds of punica granatum, the common pomegranate. Pomegranate rinds are rich in ellagic tannins that produce warm yellow-brown shades on all natural fibers. However, this is a versatile dyestuff that is often combined with other dyes or modifiers. Fibers dyed with pomegranate and dipped in a weak indigo bath turn a beautiful teal shade; alternatively, sadden with iron after dyeing to get gorgeous slate grays. A good choice for all fibers, including cotton; premordanting is optional. Use at 10% weight-of-fabric (WOF) for medium yellow-browns.

1. Background on Pomegranate

Pomegranates were first domesticated some 5,000 years ago, probably in the high valleys of the region that is now Iran (Chandra et al. 2010:1). They are one humanity’s oldest fruit crops, and they were celebrated by many ancient cultures in the Near East and Asia as both a food and a symbol of hospitality and plenty. Pomegranates are mentioned in the Bible, in the Koran, in the Buddhist sutras, and in the historical records of the Greeks, the Romans, and dynastic China (ibid). Their scientific name, punica granatum, harkens back to name the Romans gave them, malum punicum, or “apple of Carthage.”

Pomegranate seeds do not yield a usable dyestuff, but the inner rind has been used for thousands of years to tan leather and dye cloth. The rind is a rich source of natural tannins and two dyestuffs unique to the pomegranate, pelletierine and granatonine (Ajmal et al. 2014:189). These compounds give a warm yellow-brown shade on natural fibers; with the addition of iron they shift to a cool gray-green. Pomegranate colors are substantive and lightfast, so they are often combined with more fugitive dyes like turmeric to make those dyes more resistant to fading.

Pomegranate is a strong and ecologically friendly alternative to synthetic dyes. It is appropriate for all natural fibers, and it is extremely versatile when combined with different modifiers. Mordants are optional with pomegranate, so it is an excellent choice both for beginning natural dyers and for more experienced dyers looking to experiment to get a variety of shades.

An Ancient Dye and Tannin

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Pomegranate Extract, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Iron mordant. The iron used for dyeing is ferrous sulfate, sometimes labeled ferrous sulfate heptahydrate.

4. Preparation: Mordanting with Alum [Optional]

Pomegranate Extract will dye fibers that have not been mordanted, so mordanting is optional. Premordanting with alum will develop slightly clearer yellow colors, but the difference is minimal. If possible, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

For protein fibers (wool, silk, alpaca, etc.): Mordant with 10% alum and 11% cream of tartar.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.10 to calculate the amount of alum you will need, and 0.11 to calculate the amount of cream of tartar.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of cream of tartar and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Next, weight out the correct amount of alum and add it to the dye pot. Mix until well dissolved.

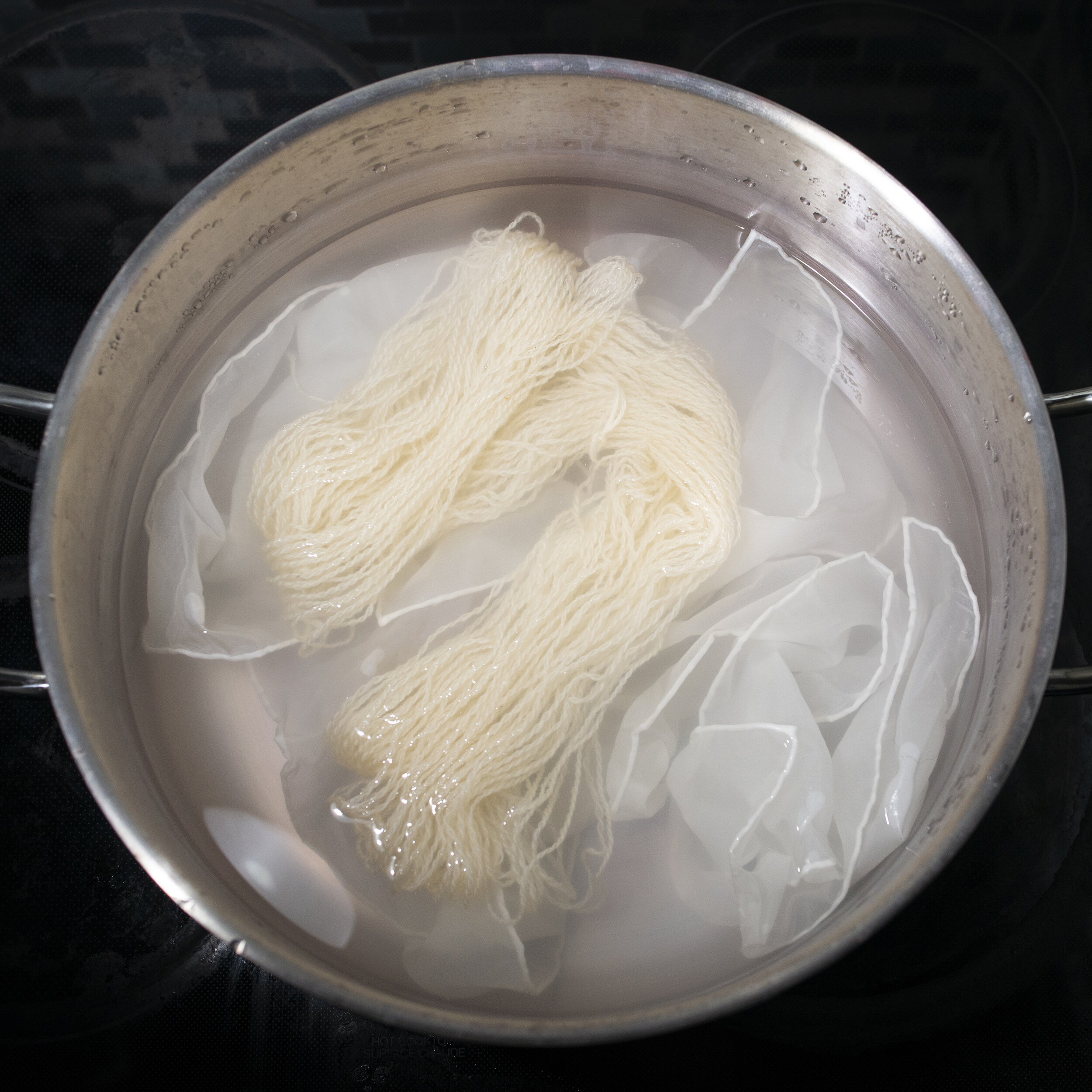

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results when dyeing thick yarn or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers briefly in lukewarm water. The fiber does not need to be thoroughly washed, but any excess mordant should be rinsed out. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Treat with a tannin before mordanting.

For best results, cotton should be tanned before mordanting with alum.

Scour cotton by adding 2 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with hot water and dissolve 10% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they bond to the mordant. Hang the cotton up and let it dry before proceeding to mordanting.

Prepare an alum mordant bath as described above for protein fibers, but omit the cream of tartar and instead add 2% weight-of-fabric soda ash (washing soda). Mix well for a few minutes before adding the cotton. This will change the alum into a basic form that bonds more easily with cotton. Proceed to mordant as described above.

The Recipes

6. Recipe: Natural Beige

Pomegranate Extract is rich enough in tannins that it can be dyed on natural fibers without a mordant. The results will be a little more brown and a little less yellow than fibers that have been premordanted with alum, but the difference is almost imperceptible. This is also a good way to prepare fibers for later saddening with iron to get gray shades, or dipping in indigo for teal.

Fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 10% weight-of-fabric (WOF) of Pomegranate Extract powder and add to the dye pot. Mix well until fully dissolved.

Add your unmordanted (but well-scoured) fiber to the dyebath.

Raise the temperature to 180°F for silk or 190-200°F for wool and cotton, then maintain for 1 hour. Stir occasionally to make sure everything dyes evenly.

After 1 hour, remove pot from heat and allow to cool until the fiber can be safely handled.

Remove the fibers and rinse briefly in warm water*. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Pomegranate Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*NOTE: If you want to sadden the fibers with iron, it is convenient to do so at this stage when the fibers have been rinsed but are still wet. You can also do it later, after the fibers are washed and dried, but you will need to soak them again before putting them in the saddening bath.

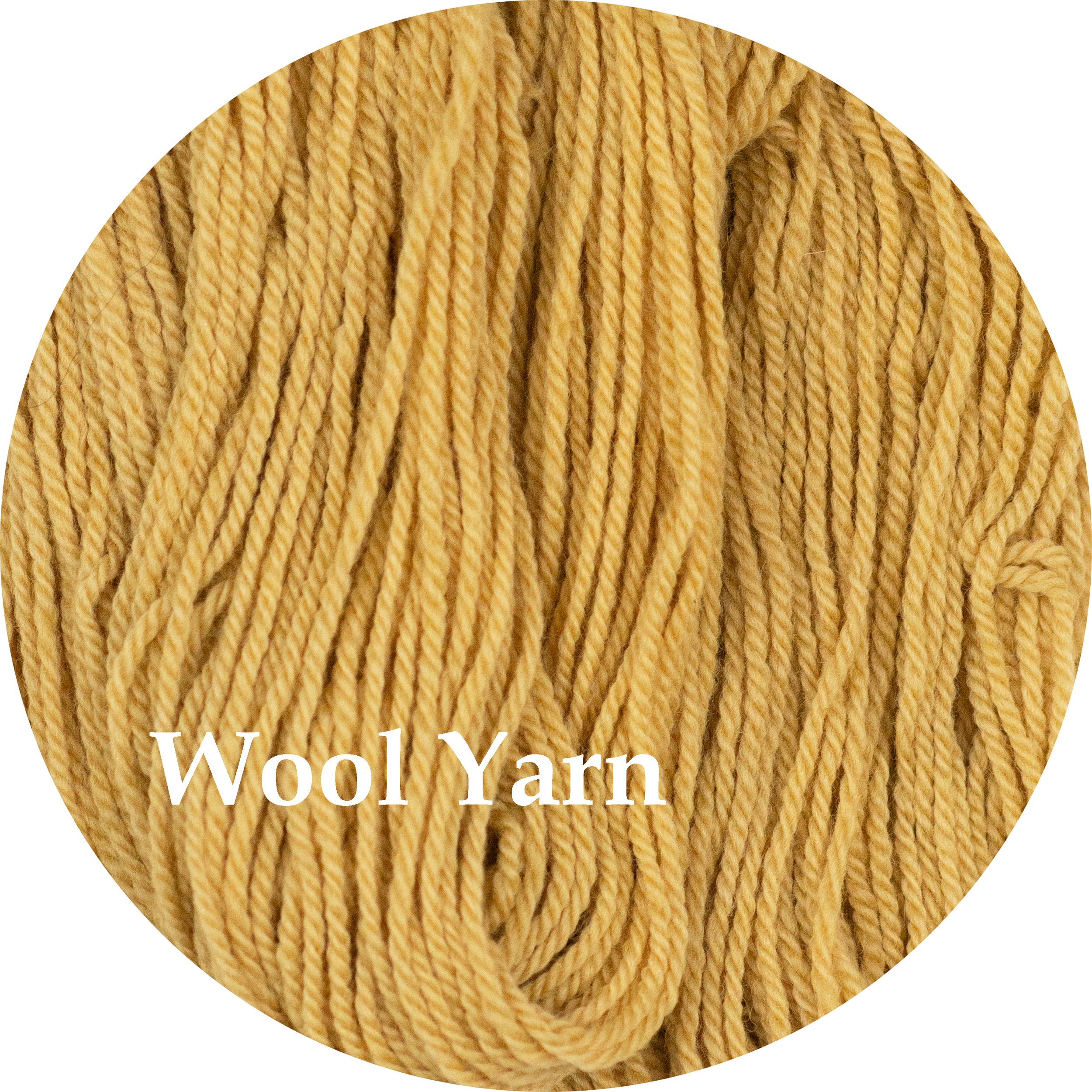

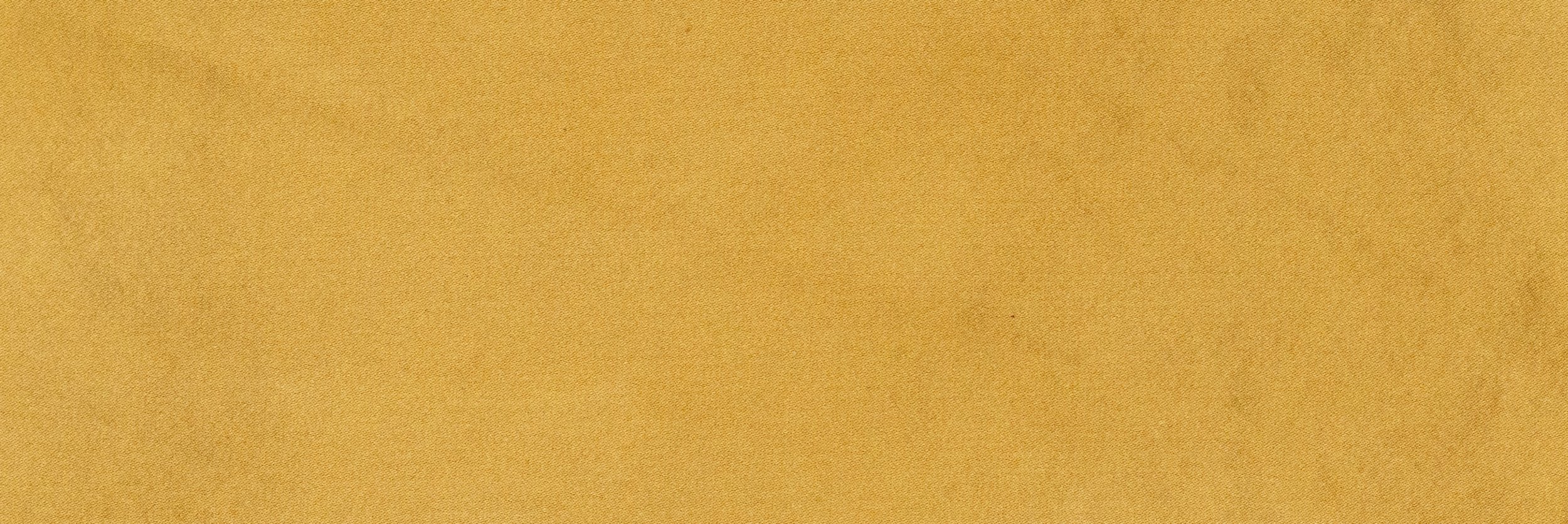

7. Recipe: Warm Beige

Dyeing Pomegranate Extract onto fibers premordanted with alum will produce a slightly clearer yellow shade. The effect is particularly nice on mulberry silk, which develops a sort of glowing golden hue. Fibers dyed with this recipe can also be saddened with iron later, or dipped in an indigo bath.

Fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 10% weight-of-fabric (WOF) of Pomegranate Extract powder and add to the dye pot. Mix well until fully dissolved.

Add your alum-mordanted fiber to the dyebath.

Raise the temperature to 180°F for silk or 190-200°F for wool and cotton, then maintain for 1 hour. Stir occasionally to make sure everything dyes evenly.

After 1 hour, remove pot from heat and allow to cool until the fiber can be safely handled.

Remove the fibers and rinse briefly in warm water*. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Pomegranate Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*NOTE: If you want to sadden the fibers with iron, it is convenient to do so at this stage when the fibers have been rinsed but are still wet. You can also do it later, after the fibers are washed and dried, but you will need to soak them again before putting them in the saddening bath.

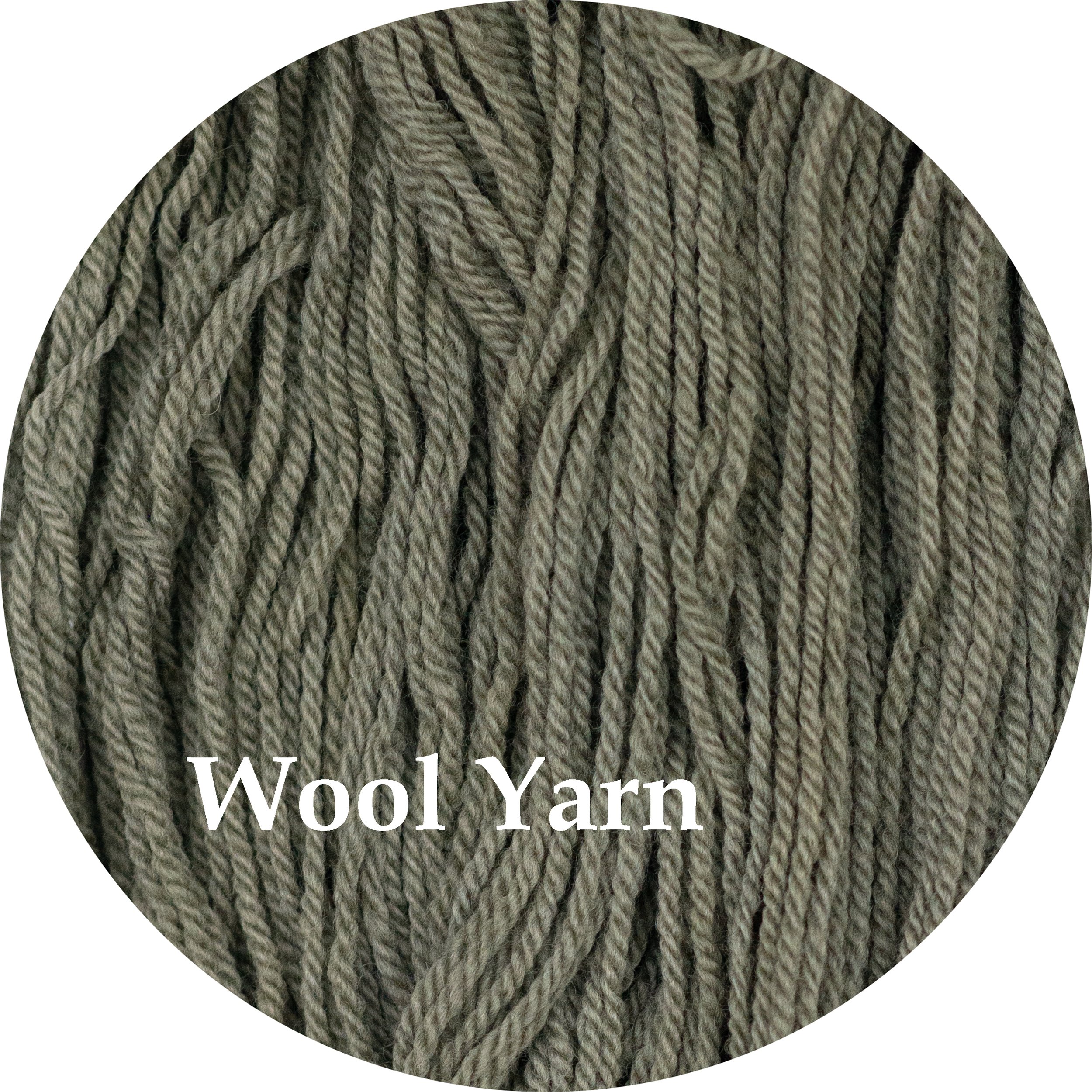

8. Recipe: Slate Grey

Pomegranate develops into excellent slate gray colors when combined with an iron mordant. It is a slightly cooler shade than the olive greens that develop when yellow dyes like weld or fustic are saddened with iron. This is a strong and lightfast color that looks particularly appealing on silk and on T-shirt cotton. The iron can be applied either immediately after dyeing, or later after the fibers have been rinsed and dried.

Dye your fibers with Pomegranate Extract according to the recipe in Section 6 (“Natural Beige”) or the recipe in Section 7 (“Warm Beige”). Both will produce fairly similar results when saddened with iron.

Make an iron saddening bath: Fill a dye pot with enough warm water for your fibers to move around freely. Add 5% weight-of-fabric (WOF) of iron mordant (ferrous sulfate). Mix well until fully dissolved*.

Raise the temperature of the saddening bath to about 120F or 130F, then place your (fully wetted out) fibers into the bath.

Raise the temperature to 180°F (for silk) or 190-200°F (for wool and cotton) and maintain for 20 minutes. Stir occasionally to make sure everything saddens evenly.

After 20 minutes, remove the fibers with tongs and rinse well in hot water. You may need to rinse more than once to make sure any excess iron is removed from the fibers.

Hang the fibers up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Red Sorghum Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*CAUTION: Ferrous sulfate (iron powder) is harmful if ingested. Keep iron and iron mordant baths away from children and pets. Avoid contact with skin and mucus membranes. Wear gloves and eye protection while handling iron powder and iron mordant baths. Dispose of the spent mordant bath according to local regulations. Read your manufacturer’s SDS (Safety Data Sheet) before working with ferrous sulfate and observe all recommended safety precautions.

9. Recipe: Teal

Fibers that are dyed with Pomegranate Extract can later be dipped in an indigo vat to get a very pretty teal shade. Make sure the fibers are clean and completely wetted out before going in the vat.

After dyeing fibers with Pomegranate Extract (either with or without a premordant - see Section 6 or Section 7), dip them in a prepared indigo vat. Make sure the fibers are well-rinsed and fully wetted before going into the vat. We recommend using a weak indigo vat for overdyeing like this - otherwise it is easy to overshoot and get too dark of a blue, which will not allow the yellow base from the pomegranate to show through.

After dipping in indigo, allow the fibers to oxidize for 30 minutes to an hour, then rinse well. Hang up to dry. Give the fibers a final full washing with a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.