Quebracho Extract

A Guide to Quebracho Extract

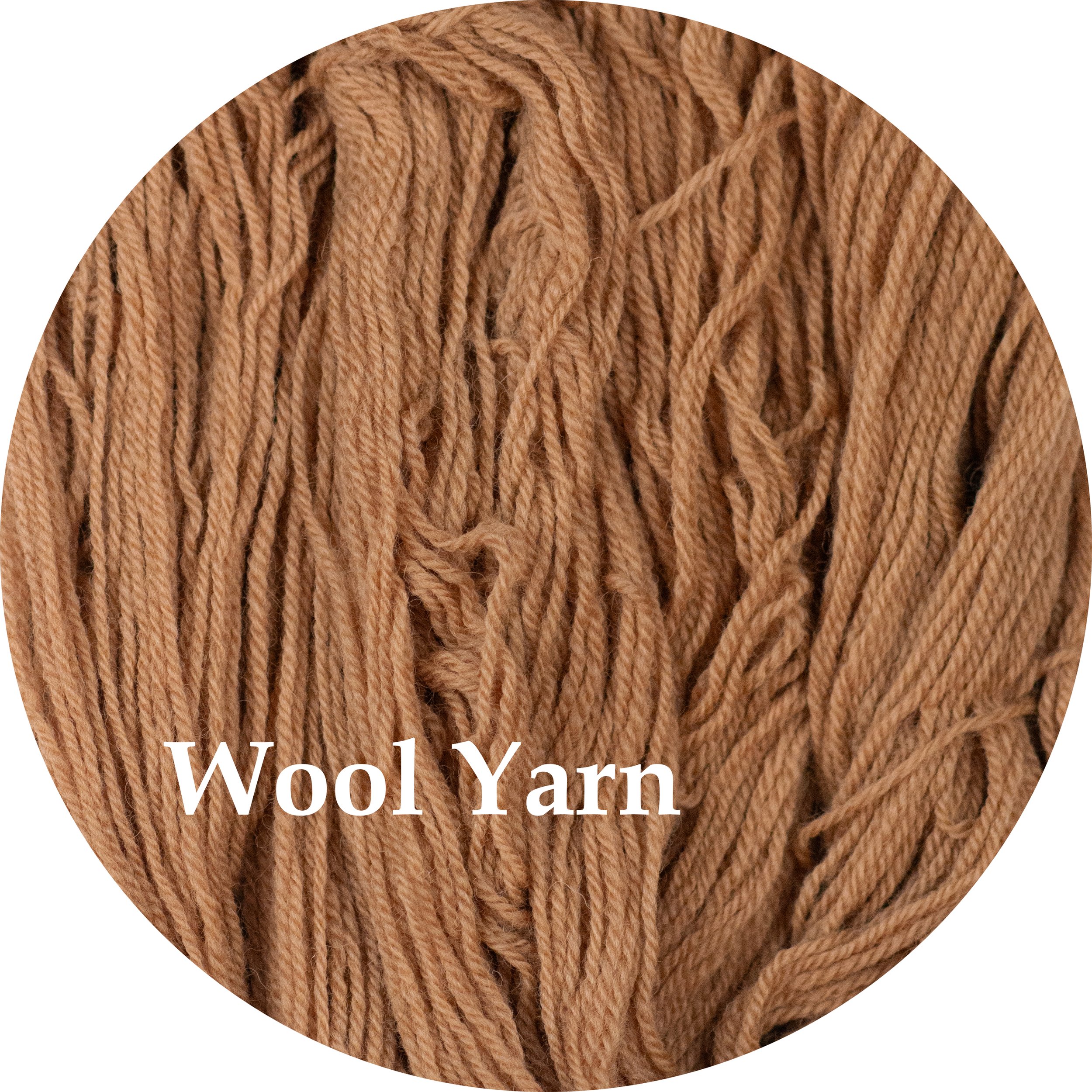

Shepherd Textiles Quebracho Extract Natural Dye is made from the heartwood of Schinopsis lorentzii, a hardwood tree native to Paraguay and Argentina. Quebracho wood is extremely hard and very rich in natural tannins, which makes it a great natural resource for tanning leather and also for dyeing fiber. Quebracho produces a series of sandy brown and soft fawn shades depending on the fiber and the mordant. Our Quebracho Extract is produced in France from South American timber by a GOTS (Global Organic Textile Standard) certified manufacturer. Use it at 10% weight-of-fabric (WOF) for warm natural browns.

1. Background on Quebracho Wood

The term “quebracho” is a portmanteau of two Spanish words, quebrar and hacha, with together translate as “axe-breaker” — an indication of how hard the wood is to chop. There are several species of South American hardwoods referred to as quebracho woods, most of them growing in Argentina, Paraguay, and Brazil. Schinopsis lorentzii, sometimes called quebracho rojo (“red quebracho”) is more common in the southern part of the continent. It produces warm shades of brown when used as a dye or tannin, and has historically been important to the local leather-tanning industry. Our Quebracho Extract is made in France from South American timber, and it is extremely rich in natural tannins. Use it for soft shades of sandy brown or fawn on all natural fibers.

Tough and Tannic

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Open carefully to avoid spills or creating dust.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Quebracho Extract powder, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

4. Preparation: Pre-Mordanting (for Silk and Cotton)

Quebracho Extract can be applied to fibers without a mordant, but the results will be rather pale. Better colors are achieved with a mordant. For wool, we recommend post-mordanting (see recipe in Section 5), so no preparation is needed other than scouring and wetting the wool before you start dyeing. For silk and cotton, we recommend pre-mordanting with alum or aluminum lactate.

For silk: Mordant at 12% WOF with alum.

Weigh out the silk fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum you will need.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 160F and maintain heat for 1 hour. Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results, especially when dyeing thick or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers briefly in lukewarm water. The fiber does not need to be thoroughly washed, but any excess mordant should be rinsed out. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of the mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Treat with 20% Sumac Extract and then mordant with 12% Aluminum Lactate.

Scour cellulose fibers well. Traditionally this is done in an alkaline soda ash solution. Add 1 tsp of soda ash and 1 drop of dish soap to a dye pot full of warm water. Add cellulose fibers and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Tan the cotton: fill your dye pot with just enough hot water for the fibers to move around freely and dissolve 20% WOF Sumac Extract into the water. Add your scoured cotton, raise the temperature to 200F, and maintain for one hour. Remove from heat and allow to cool. For best results, steep overnight. This process will make the cotton or linen more receptive to mordants. Afterwards, wring out the cotton but do not rinse it, as doing so could wash out some of the tannins that are soaked into the fibers.

Mordant with 12% Aluminum Lactate: Fill a dye pot with enough warm water for your fibers to move around freely. Measure out 12% WOF of Aluminum Lactate, add to the pot, and stir well until dissolved. Raise the heat to 140F and gently add the tanned cotton. Quickly raise the heat to 200F and maintain for 1 hour, stirring regularly to make sure the fibers mordant evenly. After an hour, turn off the heat and allow to cool to room temperature. When cool enough to handle safely, remove the fibers and gently rinse.

The Recipes

5. Recipe: Fawn Brown on Woollens

Quebracho Extract gives a series of soft, fawn-colored browns on wool that work particularly well with the post-mordanting method. Clean wool is first simmered in a Quebracho Extract dye bath until the fibers have soaked up as much of the dye as possible, and then the wool is transferred to a separate mordant bath. The final color will depend on the mordant used in this second bath - light fawn for alum, dark fawn for copper, or a sort of bark brown with iron. Postmordanting has the added advantage of making the wool very easy to rinse, as any unfixed dye will precipitate out during the mordanting step.

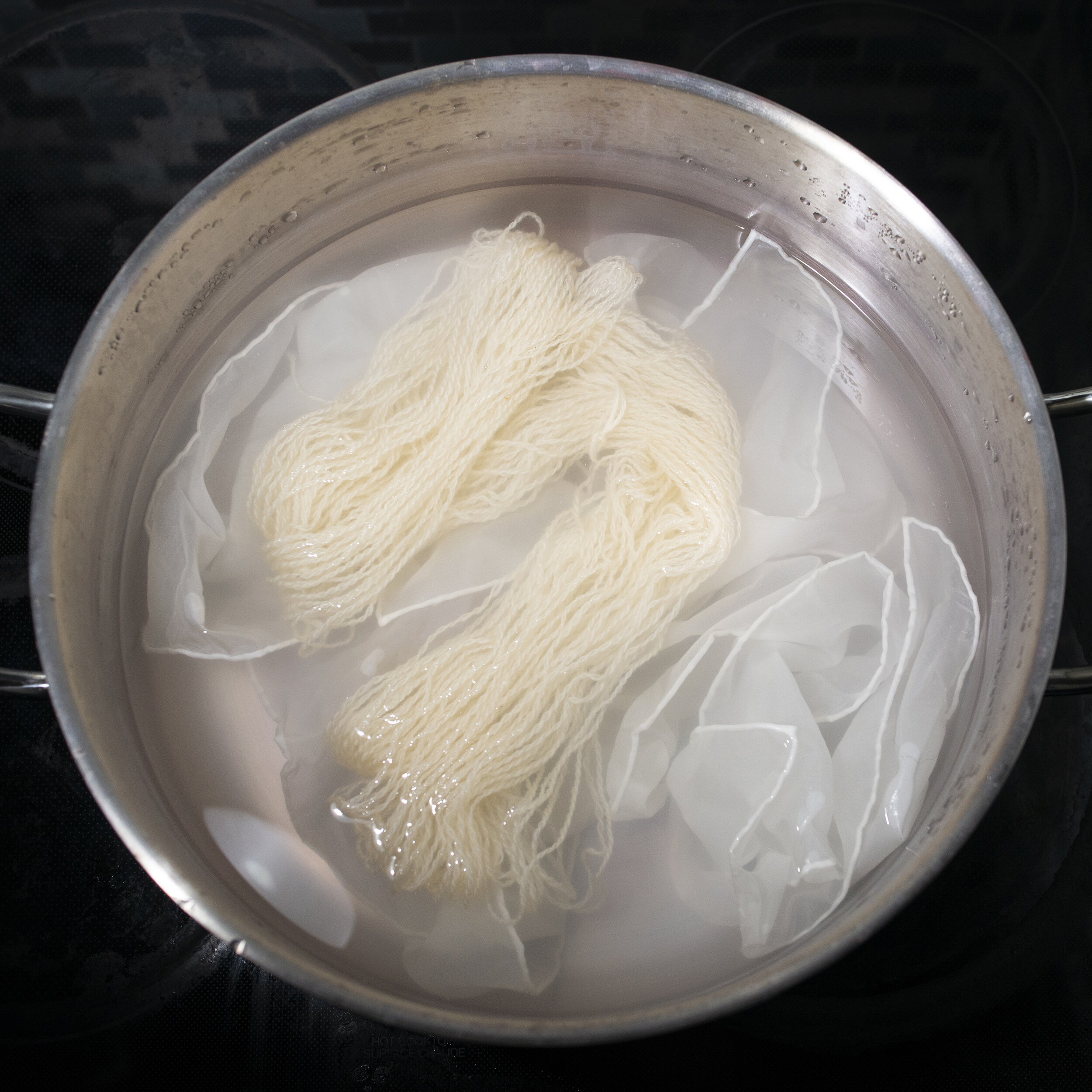

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 10% weight-of-fabric (WOF) of Quebracho Extract powder. Mix with a little bit of hot water to make a slurry (this is your chance to break up any clumps) and then add to the dye bath. Mix well. The dye bath should turn a dark ruddy brown.

Add your wetted, well-scoured (but unmordanted) wool to the dye bath.

Heat the dyebath to 180F and maintain for 1 hour, stirring occasionally to make sure all the wool dyes evenly. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, prepare a mordant bath in a second dye pot. Fill it with enough warm water for your fibers to move around freely. Add one of the following: 10% WOF alum (for light fawn), 4% WOF copper sulfate (for dark fawn) or 2% WOF iron sulfate (for bark brown). Mix the mordant powder into the water until fully dissolved.

Heat the mordant bath to 130F. Lift the dyed wool out of the dye bath and let most of the excess liquid drip back off into the dye bath. Then, gently place the wool into the mordant bath.

Heat the mordant bath to 180F. Maintain this temperature for 30 minutes (for alum or copper) or 5 minutes (for iron). This should be long enough for the mordant to bond with the dye and to “sadden” the color of the wool.

Turn off the heat and let cool until the wool can be safely handled. Remove with tongs and rinse gently in warm water with a drop or two of pH-neutral soap, such as Synthrapol. Follow the manufacturer’s directions for best results. CAUTION: Quebracho Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

6. Recipe: Sandy Brown

With cotton and silk, Quebracho Extract gives the best results on fibers that are premordanted rather than postmordanted. Combining it with an alum mordant will produce a soft, sandy brown that looks very natural - indeed, it could easily be mistaken for the color of raw, unbleached linen or jute.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 10% weight-of-fabric (WOF) of Quebracho Extract powder. Mix with a little bit of hot water to make a slurry (this is your chance to break up any clumps) and then add to the dye bath. Mix well. The dye bath should turn a dark ruddy brown.

Add cotton or silk fibers that have been mordanted with alum to the dye bath.

Heat the dyebath to 200F (for cotton) or 160F (for silk) and maintain for 1 hour, stirring occasionally to make sure all the fibers dye evenly. After 1 hour, turn off the heat and allow to cool to room temperature. Continue stirring occasionally while the fibers cool.

Once cool, remove the fibers and rinse gently in warm water with a few drops of pH-neutral soap, such as Synthrapol. Follow the manufacturer’s directions for best results. CAUTION: Quebracho Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.