Cape Jasmine Extract

(Gardenia Blue)

A Guide to Cape Jasmine Extract

Shepherd Textiles Cape Jasmine Extract is made from the fruit of the Cape Jasmine, gardenia jasminoides. It is one of the only natural blues besides indigo, and it has the advantage of not needing a reduction vat like indigo does. It gives a bright, beautiful sky blue on silk, and on wool can yield shades from pale powder blue to dark undersea blue. We do not recommend it for cellulose fibers like cotton and linen, because it will leave only the faintest trace of color, if any. Use Indigo or Royal Logwood Extract instead.

1. Background on Cape Jasmine

The Cape Jasmine, gardenia jasminoides, is a flowering shrub native to southern China. The dried fruit has been used as a natural yellow dye for many centuries. In the late 1980s, however, a Japanese scientist discovered that one of the compounds in Cape Jasmine could be converted to a blue pigment instead (see Cho et al. 2006:230; Hobbs et al. 2018:696). The process involves reacting genipin in the fruit with one of the basic amino acids, like glycine (found in legumes) or tyrosine (found in cheese). This leads to the formation of a blue pigment often referred to as Gardenia Blue.

There are only a handful of natural blue dye besides indigo, including spirulina (made from algae) and red cabbage extract. Blue Gardenia has major advantages over them; it it is stable at high and low PH and does not degrade when heated. It is already extremely popular in East Asia, especially in Korea. It is used to color frosting, cakes, ice cream, cosmetics, and blue drinks. However, it remains virtually unknown in the United States. The FDA currently has a working group evaluating Gardenia Blue, but until it receives FDA approval it cannot be used to color foods and cosmetics in the U.S. If and when it does receive approval, it will probably become quite popular.

Like some of the other newer natural dyes (e.g., Mulberry Leaf Extract), Cape Jasmine Extract behaves differently in the dyebath. PH does not affect color but it does effect how well it bonds to fiber: many studies have found that PH4 is ideal. It also seems to compete rather than bond to certain mordants; pre-mordanting with copper will prevent dye uptake. However, alternate strategies, like post-mordanting and meta-mordanting (mordanting and dyeing in the same bath) can be effective. This is a new dye with few existing guides, and it will reward dyers who enjoy experimenting.

2. Safety Precautions

DO NOT INGEST. This extract is intended for textile dyeing, not as a food colorant.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Cape Jasmine Extract can permanently dye clothing, countertops, rugs, utensils, or other property. Avoid contact with anything that is not meant to be dyed.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Cape Jasmine Extract, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely. Otherwise, particles of dye may get stuck on the fabric and cause dark splotches.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling extract powder and while handling mordanted/dyed fiber before it is rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and extract powder.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Disposable cup. For mixing the extract powder to a paste.

4. Preparation: Mordanting with Alum

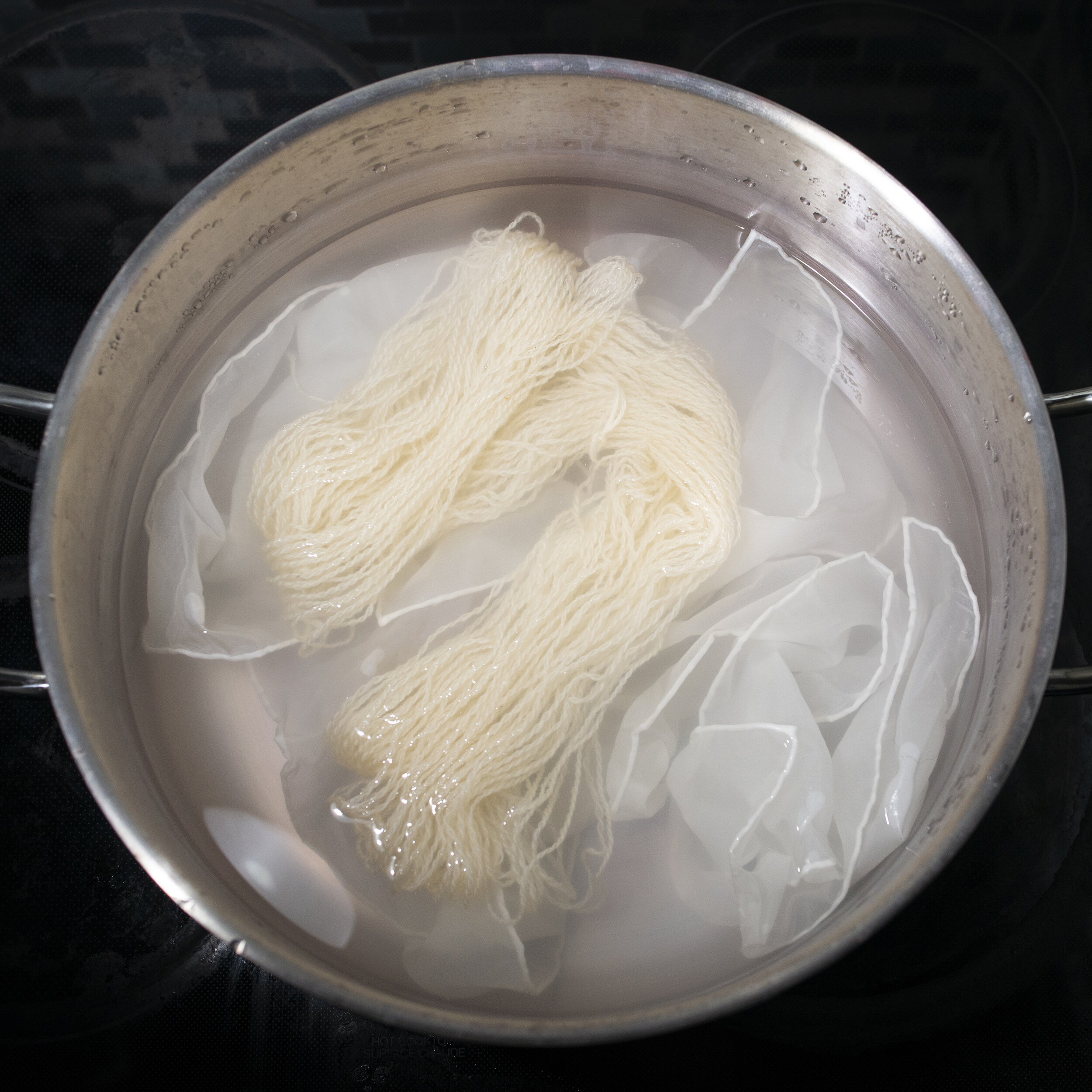

Cape Jasmine bonds most effectively to protein fibers that have been mordanted with alum. For best results, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

Alum will dissolve quickly into hot tap water.

Heat fibers for an hour at 180F, then allow to cool.

For protein fibers (wool, silk, cotton, etc.): Mordant at 12% WOF with alum.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum you will need.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This will improve results, especially when dyeing thick or tightly woven fabrics.

Remove cooled fibers. Wearing rubber gloves, gently squeeze excess mordant solution back into the pot. Rinse briefly in lukewarm water. The fiber does not need to be thoroughly washed, but any excess alum should be rinsed out. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Use Indigo or Royal Logwood Extract instead.

Cape Jasmine Extract will have no effect on cotton, no matter how well it has been mordanted. There are some papers in Korean journals that state that cotton can be dyed with Cape Jasmine Extract if the cotton is pre-treated with chitosan first (e.g., Ko 2011:21-27). Chitosan is a sugar made from the chitin in shrimp shells: it is supposed to bond chemically to cotton to make it more receptive to mordants and natural dyes. However, in our experiments with chitosan, the improvement in dye uptake was very faint. If you do want to give it a try, there are a few papers in English that discuss chitosan mordanting. Please let us know if you can figure out a good recipe! Otherwise, if you want to get a good blue on cotton, we recommend using indigo or logwood with a copper mordant. Both options will give deep blues on cotton without too much trouble.

The Recipes

5. Recipe: Sky Blue

The basic recipe for Cape Jasmine Extract is to use 5% weight-of-fabric (WOF) on alum-mordanted fiber to produce a bright sky blue. For darker blues, increase the WOF to 10%.

Fill your dye pot with warm water, making sure there is enough room for the fabric to move around and for water to circulate freely.

Adjust the PH to 4 with white vinegar or citric acid. If you don’t have PH strips, just add a tablespoon or two of white vinegar to approximate a slightly acidic dye bath.

Weigh out 5% weight-of-fabric (WOF) Cape Jasmine Extract into a disposable cup (multiply the dry weight of the fabric by 0.05 to get the correct amount of extract).

Add a little hot water to the cup and mix to form a thin slurry. Make sure to break up any clumps of powder, otherwise they may cause splotches on your fiber.

Pour the Cape Jasmine Extract slurry into the dyebath and mix well. At this point the dyebath will be a dark blue color.

Add your pre-mordanted, wetted fibers to the dyebath.

Raise the temperature to 180°F. Maintain for 1 hour to 1.5 hours, stirring every 20 minutes or so to make sure everything dyes evenly.

After 1 or 1.5 hours, remove pot from heat and allow to cool to room temperature. Since Cape Jasmine Extract dissolves fully in water, the fiber can be left in the dye bath overnight to deepen the color without any risk of splotches developing.

Remove the fibers and rinse briefly in lukewarm water to remove any particles of dye. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up somewhere where dripping dye will cause no damage.

For final rinsing, we recommend using detergent like Synthrapol which is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Cape Jasmine Extract will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

6. Recipe: Turquoise

Cape Jasmine Extract does not always respond well to the classic pre-mordanting strategy used in natural dyeing. One study found that post-mordanting or meta-mordanting (mordanting and dyeing in the same bath) could give better results. This seems to be especially true when using copper. The greenish tint on copper will turn the clear sky blue of Blue Gardenia toward turquoise, but the mordant should be added to the dye bath after the fiber has already been mostly dyed. Otherwise it seems to interfere with dye take-up.

Fill your dye pot with warm water, making sure there is enough room for the fabric to move around and for water to circulate freely.

Adjust the PH to acidic (4) with white vinegar or citric acid/lemon juice. If you don’t have PH strips, add two tablespoons of white vinegar for every 5 gallons of water to approximate a PH of 4.

Weigh out 5-10% weight-of-fabric (WOF) Cape Jasmine Extract into a disposable cup (multiply the dry weight of the fabric by 0.05 or 0.10 to get the correct amount of extract).

Add a little hot water to the cup and mix to form a thin slurry. Make sure to break up any clumps of powder, otherwise they may cause splotches on your fiber.

Pour the Cape Jasmine Extract slurry into the dyebath and mix well. At this point the dyebath will be a dark blue color.

Add unmordanted, wetted fibers to the dyebath.

Raise the temperature to 180°F. Maintain for 1 hour, stirring every 20 minutes or so to make sure everything dyes evenly.

After 1 hour, measure out 1% WOF copper powder into a disposable cup. Add a little hot tap water and mix well to dissolve. Add the dissolved copper to the dyebath and mix well. For best results, lift the fiber out with tongs while you add the copper solution so it does not fall directly on any particular piece of fiber.

Maintain temperature at 180°F for another 30 minutes. Remove dye pot from heat and allow to cool.

Remove the fibers and rinse briefly in lukewarm water to remove any particles of dye. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up somewhere where dripping dye will cause no damage.

For final rinsing, we recommend using a PH-neutral detergent like Synthrapol, since they are designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Cape Jasmine Extract will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

References:

Cape Jasmine Extract is a relatively new natural dye and there is little published information about it in English. Some of the techniques we use—like adjusting the PH to 4—were adapted from experimental studies on dyeing with Gardenia Blue. Some are in Korean, but the figure captions are in English. Natural dyers interested in experimenting with Cape Jasmine Extract may want look these up for ideas. Note that there are some conflicting results; take these as starting points, not as definite conclusions.

Fangbin, Shen, Ding Yi, and Xiao Ruobai.

(2021) Dyeing Properties of Cashmere Fiber Dyed with Gardenia Blue Pigment. Journal of Physics: Conference Series 1790:1-9.

TL;DR: The authors found when dyeing cashmere with Gardenia Blue, the ideal parameters are a PH of 4, a temperature of 75°C/170°F, WOF of 7.5%, and only 50 minutes of dye time. Similar parameters may apply to wool (although we find that extending dye time to 2 hours can improve results).

Cho, Y.J., S.Y. Kim, J. Kim, E.K. Choe, S.I. Kim, and H.J. Shin

(2006) One-Step Enzymatic Synthesis of Blue Pigments from Geniposide for Fabric Dyeing. Biotechnology and Bioprocess Engineering 11:230-234.

TL;DR: The authors find that the optimal dye bath parameters for cotton are PH 4.2 and temperature 60°C/140°F; for silk, PH 3.2 and 70°C/160°F. In both cases, 1 hour was the ideal dyeing time.

Ko, Hye-Ri

(2011) Study on Dyeability of Cotton Fabrics Dyed with Natural Gardenia Blue Powder. Textile Coloration and Finishing 23(1): 21-27). [In Korean]

TL;DR: The author finds that chitosan pre-treatment improves Gardenia Blue results on cotton by up to 5x. “High molecular count” chitosan is superior to “low molecular count” chitosan. Ideal dye bath parameters for cotton are PH of 3.5 and temperature of 70°C/160°F.

Kim, Sang-Yool

(2004) Natural Dyeing of Silk Using Gardenia Blue. Journal of Korean Society of Clothing Industry 6(6): 778-785 [In Korean]

TL;DR: The author finds that pre-mordanting silk does not significantly improve lightfastness or color-fastness, and that post-mordanting and meta-mordanting yield equal or slightly superior results. Note that the cashmere study found that pre-mordanting did improve fastness, so the results here should not be taken as conclusive.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without permission and attribution.