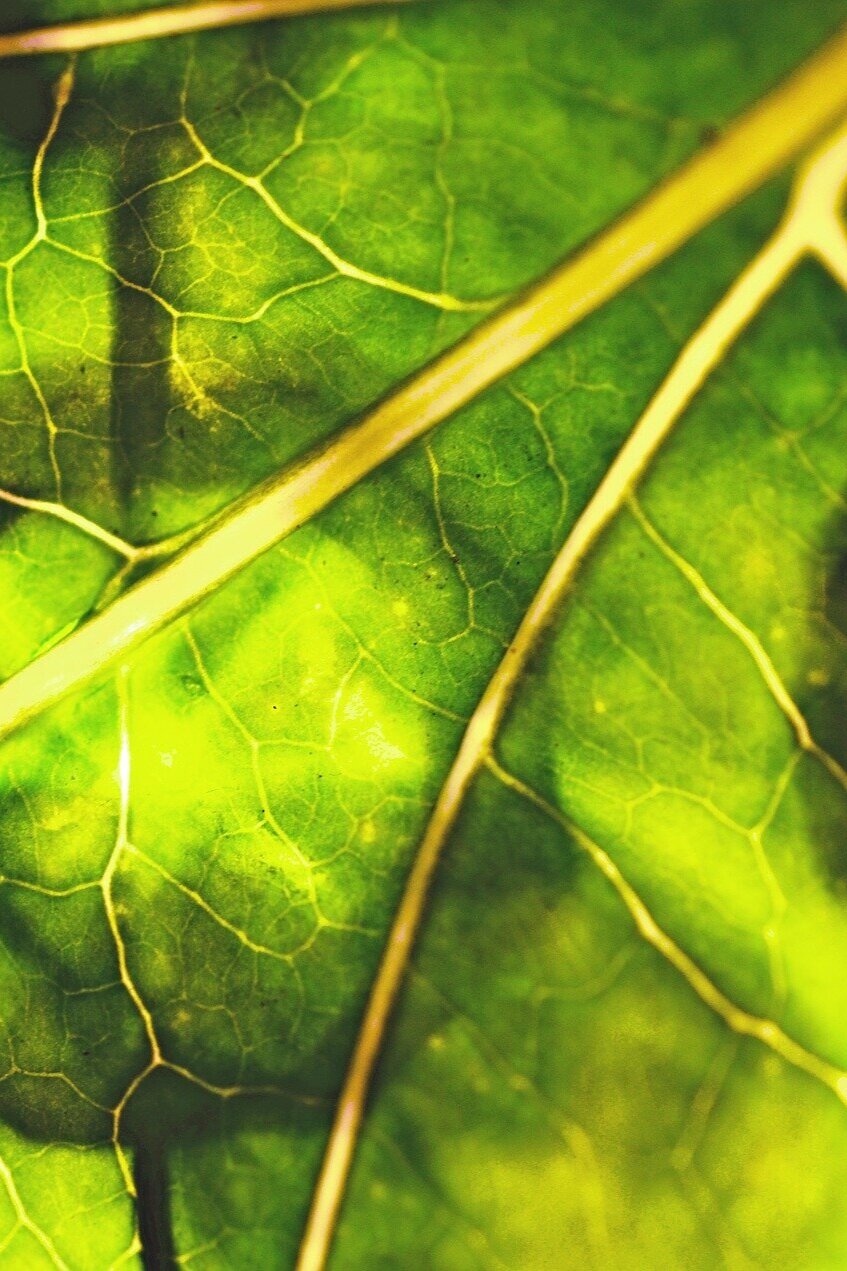

Mulberry Leaf Extract

Dyeing with Mulberry Leaf Extract (Chlorophyllin)

Shepherd Textiles Mulberry Leaf Extract is made from the natural chlorophyll in the leaves of morus alba, the white mulberry tree. The leaves are simmered with a copper mordant to convert the chlorophyll to a more stable form called chlorophyllin, which is resistant to sunlight and heat. Mulberry Leaf Extract produces a range of very natural-looking greens, from pale jade greens to deep forest greens, depending on fiber type. Use at 5%-10% for medium and dark shades. Product of India. Produced by a GOTS (Global Organic Textile Standard) certified manufacturer.

1. Background on Chlorophyllin

Nature’s Green

The primary dyestuff in Shepherd Textiles Mulberry Leaf Extract is a green chemical called chlorophyllin that is derived from the natural chlorophyll in green leaves. The chlorophyll in plants is easily denatured by sunlight, oxygen, or acids: fallen leaves and dead grass lose their color because the chlorophyll in them quickly breaks down. However, chlorophyll can be converted into a more stable form called chlorophyllin by boiling dried green plant matter in a 5% copper sulfate solution and then saponifying it with a tiny bit of lye (Park and Park 2010:358). Chlorophyllin is being studied for its medical potential, and some literature indicates it may have potent anti-oxidant and anticancer effects (e.g., Nagini et al. 2015). Chlorophyllin is also water-soluble and retains its green color when heated, making it suitable for dyeing textiles.

Chlorophyllin behaves differently from other natural dyes. Adjusting the PH of the dyebath has no effect on the color produced, and mordant after-washes have limited effect. Changing the shade is mostly a matter of using more or less extract, or overdyeing it with other colors. Different sources of chlorophyllin also seem to yield slightly different hues. Extracts produced from nettle and alfalfa tend towards bluer greens, whereas the chlorophyllin produced from mulberry leaves tends toward hunter greens and jade greens. This may be a result of varying proportions of chlorophyll A to chlorophyll B in the plant sources. Mulberry chlorophyllin also has a very distinct smell that you may or may not find pleasant, depending on how you feel about the smell of green tea. With an alum mordant, mulberry chlorophyllin will produce a range of beautiful grass- and forest-colored greens on natural fibers.

2. Safety Precautions

DO NOT INGEST. This extract was prepared for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Do not use as a cosmetic additive, or apply directly to skin or hair.

Open carefully to avoid spilling or creating dust.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Mulberry Leaf Extract can permanently dye clothing, countertops, rugs, utensils, or other property. Avoid contact with anything that is not meant to be dyed.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Mulberry Leaf Extract, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

CAUTION: Do not use an iron after-wash when dyeing with Mulberry Leaf Extract. In our experiments, it created some deeply unpleasant-smelling and eye-watering fumes.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely. Otherwise, particles of dye may get stuck on the fabric and cause dark splotches.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling extract powder and while handling mordanted/dyed fiber before it is rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and extract powder.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Disposable cup. For mixing the extract powder to a paste.

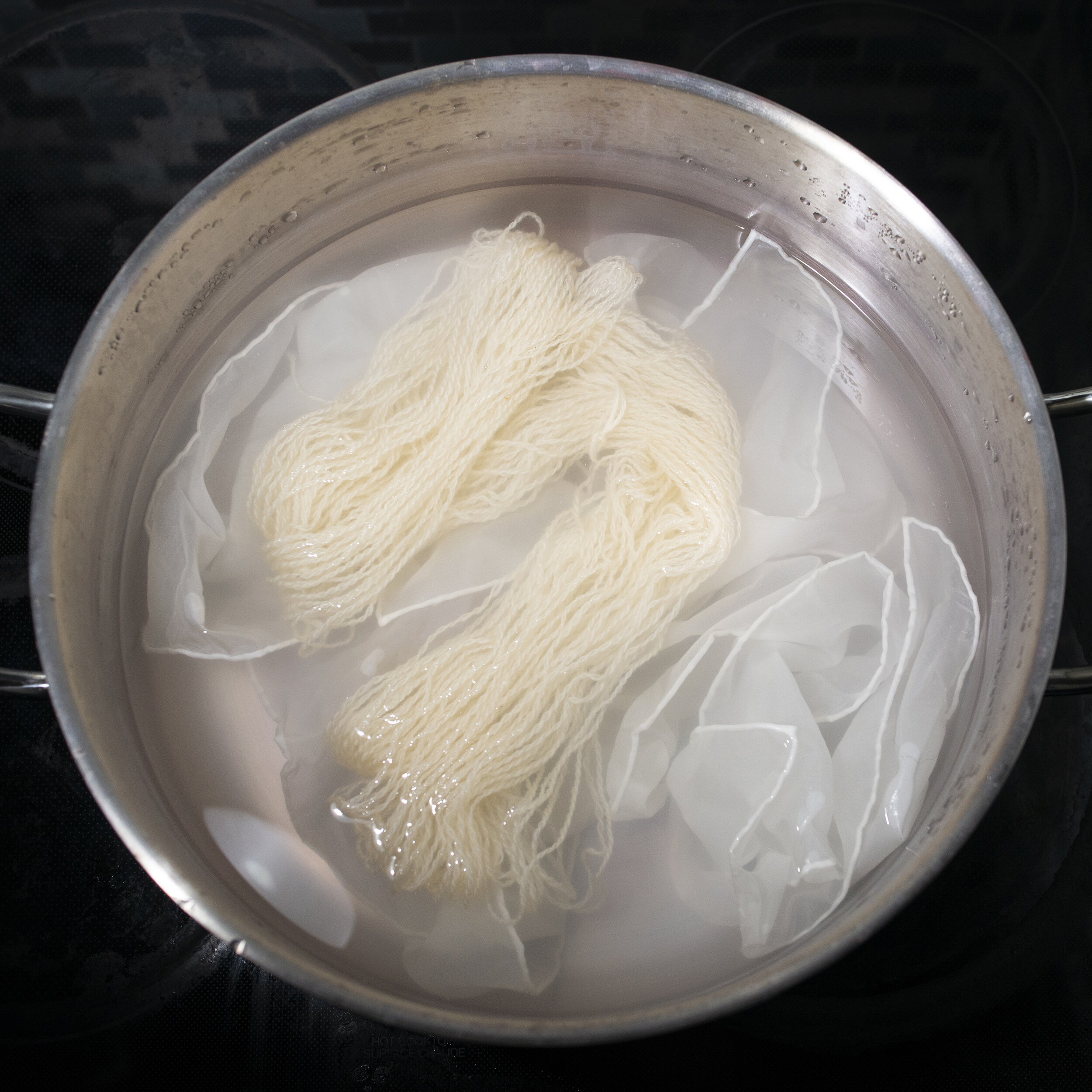

4. Preparation: Mordanting with Alum

Chlorophyllin bonds most effectively to fibers that have been mordanted with alum. For best results, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

Alum will dissolve quickly into hot tap water.

Heat fibers for an hour at 180F, then allow to cool.

For protein fibers (wool, silk, alpaca): Mordant at 12% WOF with alum.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum you will need.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This will improve results, especially when dyeing thick or tightly woven fabrics.

Remove cooled fibers. Wearing rubber gloves, gently squeeze excess mordant solution back into the pot. Rinse briefly in lukewarm water. The fiber does not need to be thoroughly washed, but any excess alum should be rinsed out. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Pre-treat with a tannin before mordanting at 12% WOF with alum.

Cellulose fibers are more resistant to alum than protein fibers, and may need to be treated with a tannin first so they will absorb the alum better. In our experience, success dyeing cellulose fibers depends very much on the quality of fiber used. Handspun, handloom, and organic cotton and linen tend to take natural dyes well, and you can skip the optional tannin step and still get good results. However, commercial cotton tends to be more resistant to natural dyes, possibly because of industrial finishing. It will often need to undergo a two-step process with a tannin and a mordant.

Scour cellulose fibers well. Traditionally this is done in a highly alkaline soda ash solution, but standard household detergents like Tide© are equally alkaline (PH 11), so we prefer to just toss the fiber in the washing machine on an high-temperature cycle with plenty of detergent.

[OPTIONAL] Apply a clear or light-colored tannin to the scoured fabric. Some good choices are Gallnut Extract, Tara, Sumac, or Myrobalan. To use, fill your dye pot with hot water, dissolve 2-5% WOF of your chosen tannin in the dye bath (check vendor’s instructions—each will need a slightly different WOF) and simmer for an hour. Be very careful to keep the fiber moving around: some tannins have insoluble particles that love to get stuck in fabric, and they can cause splotches later on in the dyeing process. After an hour, let cool, remove fibers and rinse well.

Mordant with alum as described above for protein fibers, but add 2% weight-of-fabric (WOF) of soda ash to the alum before adding the fibers. This will convert the alum to a more basic form that will bond more easily with plant fibers.

The Recipe

5. Recipe: Forest Green

The basic recipe for Mulberry Leaf Extract is to use 5% weight-of-fabric (WOF) on alum-mordanted fiber to produce a forest green. However, the final color may vary wildly depending on the fiber type. In the same dyebath, normal wool could come out dark green, alpaca a soft lime, silk almost neon, and super-wash merino closer to a seaweed color. Success with chlorophyllin also depends on the fiber being thoroughly mordanted and totally pre-soaked before going in the dyebath.

Fill your dye pot with warm water, making sure there is enough room for the fabric to move around and for water to circulate freely.

Weigh out 5% weight-of-fabric (WOF) Mulberry Leaf Extract into a disposable cup (multiply the dry weight of the fabric by 0.05 to get the correct amount of extract).

Add a little hot water to the cup and mix to form a thin slurry. Make sure to break up any clumps of powder, otherwise they may cause splotches on your fiber.

Pour the Mulberry Leaf slurry into the dyebath and mix well. At this point the dyebath will be dark green.

Add your pre-mordanted, wetted fibers to the dyebath.

Raise the temperature to 180°F for protein fibers or 200°F for cotton. Maintain for 45 minutes to 1 hour, stirring every 20 minutes or so to make sure everything dyes evenly.

After 45 minutes to an hour, remove pot from heat and allow to cool to room temperature.

Remove the fibers and rinse briefly in lukewarm water to remove any particles of dye. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up somewhere where dripping dye will cause no damage.

For final rinsing, we recommend using a PH-neutral detergent sold for textile artists, since they are designed to wash out loose dye. Follow the manufacturer’s directions for best results. Be careful using commercial laundry detergents: most are extremely alkaline, and may shift the color of the fabric. CAUTION: Madder will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.