Wild Madder Extract

Wild Madder

FOR THE CLASSIC “TURKEY RED”

Shepherd Textiles Wild Madder Extract is produced from wild-harvested rubia tinctorum, the true Turkish madder. The wild roots develop a high concentration of the red dye alizarin, which makes it possible to achieve a beautiful and consistent “Turkey red.” The best shades of scarlet and crimson are produced with an alum mordant, while orange and purple develop when combined with tin or iron. Suitable for all natural fibers, and will produce richly saturated shades on wool, silk, and cotton. Product of India. Produced by a GOTS (Global Organic Textile Standard) certified manufacturer.

1. Background on Madder Root

The Most Permanent Natural Red

“Madder” refers to two species of flowering shrubs in the genus rubiaceae, the same family that includes coffee and gardenias. Rubia tinctorum is known as Dyer’s Madder or Turkish Madder; Rubia cordifolia is commonly known as Indian Madder. Both species produce dozens of anthraquinone compounds in their roots. Several of these are strong natural dyes, and they each produce a different hue. For example, purpurin in the roots produces oranges and yellows, while alizarin produces brilliant, clear reds. This chemical complexity makes raw madder roots extremely challenging to work with, because depending on the temperature, PH, and mordanting process, the orange and brown dyes can easily overpower the red.

Dyers in Anatolia developed a complex process for getting a strong, clear crimson out of madder roots. Fabrics dyed with this “Turkish Red” were highly coveted in Europe, where the secret of getting such a clear red out of madder was not known. European dyers went to extremes to try to recreate it: contemporary recipes suggested steps like pre-mordanting the fiber with dung to “animalize” it, or adding sheep’s blood to the dye bath to increase the depth of the red (see Chenciner 2000:193). Madder fascinated and frustrated dyers for centuries, until the alizarin in the roots was isolated by chemists in France in 1862. In 1871 synthetic alizarin became available, which lead to the end madder’s reign as the classic red plant dye.

2. Safety Precautions

Do not ingest. This extract was prepared for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust.

Wild Madder Extract can permanently dye clothing, countertops, rugs, utensils, or other property. Avoid contact with anything that is not meant to be dyed.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Wild Madder Extract, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely. The best choice for madder is a large stock pot with a non-stick surface. Madder can stain stainless steel pots. If that happens, the pink stains can usually be scrubbed out with a scouring pad.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling extract powder and while handling mordanted/dyed fiber before it is rinsed.

Candy thermometer. Madder creates the clearest reds when dyed at 180F. The best way to keep track of temperature is to use a cheap candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and extract powder.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

PH strips. For adjusting the dye bath PH.

Disposable cup. For mixing the extract powder to a paste.

4. Preparation: Mordanting with Alum

Madder bonds most effectively to fibers that have been mordanted with alum. In fact, chemists who have analyzed old textiles dyed with “Turkish Red” have found that the color is actually a compound formed by the reaction of the alizarin with aluminum and calcium (see Taha 2014:22). For best results, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

Alum will dissolve quickly into hot tap water.

Heat fibers for an hour at 180F, then allow to cool.

For protein fibers (wool, silk, alpaca): Mordant at 12% WOF with alum.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum you will need.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This will improve results, especially when dyeing thick or tightly woven fabrics.

Remove cooled fibers. Wearing rubber gloves, gently squeeze excess mordant solution back into the pot. Rinse briefly in lukewarm water. The fiber does not need to be thoroughly washed, but any excess alum should be rinsed out. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Pre-treat with a tannin before mordanting with alum.

Cellulose fibers are more resistant to alum than protein fibers, which makes them more difficult to mordant. For best results, treat plant fibers like cotton with a tannin like Sumac Extract before mordanting them with alum.

Scour (clean) the cotton by adding 1 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with just enough hot water for your fibers to move around freely. Dissolve 10% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they bond to the mordant. You may proceed to mordanting immediately, but for slightly stronger results you can hang the cotton up and let it dry first before mordanting.

Prepare an alum mordant bath as described above for protein fibers, but use 20% weight-of-fabric alum and add 5% weight-of-fabric soda ash (washing soda). Mix the alum and soda ash well for a few minutes before adding the cotton. This will change the alum into a basic form that bonds more easily with cotton. Proceed to mordant as described above. (Alternately, you can use 12% aluminum lactate instead of the alum + soda ash).

Recipes

5. Recipe - Turkish Red

Getting the deep, clear crimson known as “Turkish Red” requires three things: fiber thoroughly mordanted with alum, a slightly acidic dyebath, and a consistent temperature of 180F. This recipe will guide you through the steps to getting an intense crimson from your Wild Madder Extract.

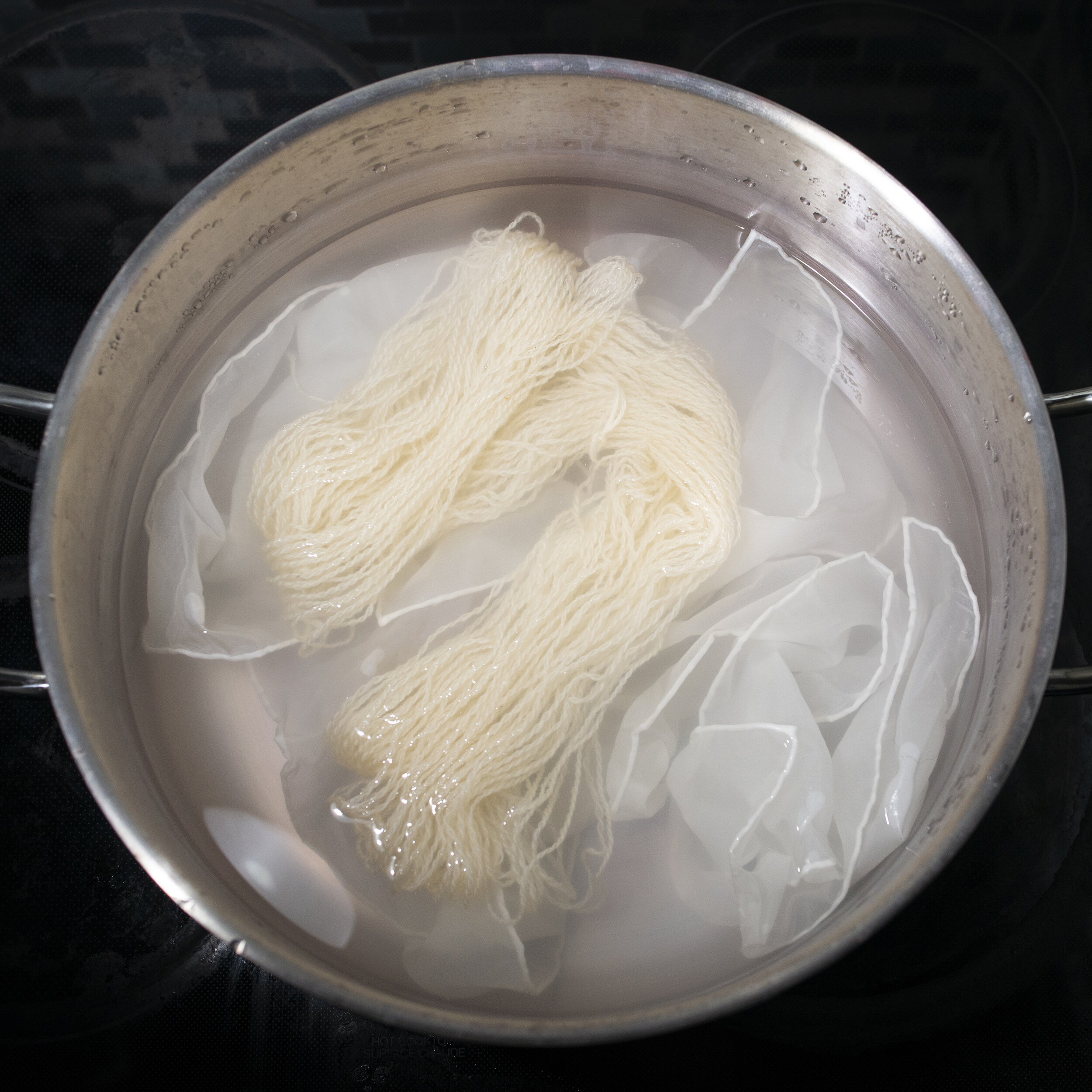

Fill your dye pot with warm water, making sure there is enough room for the fabric to move around and for water to circulate freely.

Adjust the PH to 5 with white vinegar. If you don’t have PH strips, add two tablespoons of white vinegar to approximate a slightly acidic dye bath.

Weigh out 5% weight-of-fabric (WOF) Wild Madder Extract into a disposable cup (multiply the dry weight of the fabric by 0.05 to get the correct amount of extract).

Add a little hot water to the cup and mix to form a thin slurry. Make sure to break up any clumps of powder, otherwise they may cause splotches on your fiber.

Pour the madder slurry into the dyebath and mix well. At this point the dyebath will be a muddy brown.

Add your pre-mordanted fibers to the dyebath.

Raise the temperature to 180F and maintain for 1.5-2 hours, stirring every 20 minutes or so to make sure everything dyes evenly.

After 1.5 or 2 hours, remove pot from heat and allow to cool to room temperature.

Remove the fibers and rinse briefly in lukewarm water to remove any particles of dye. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up somewhere where dripping dye will cause no damage.

For final rinsing, we recommend using a PH-neutral detergent sold for textile artists, since they are designed to wash out loose dye. Follow the manufacturer’s directions for best results. Be careful using commercial laundry detergents: most are extremely alkaline, and may shift the color of the fabric. CAUTION: Madder will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

NOTE: Results will vary depending on the fiber type and how thoroughly it is mordanted with alum. Alpaca, superwash wool, and cotton tend to yield slightly more pale reds while wool, silk, and linen will produce deep reds more easily.

6. Recipe - Rusty Purple

The recipe for getting “Rusty Purple” is really just a quick afterwash to use after following the recipe for dyeing Turkish Red. It takes advantage of the chemical properties of iron, which tends to “sadden” natural dyes by drawing out darker hues. Madder red will turn to a reddish eggplant purple.

Follow the recipe for “Turkish Red” described in Part 5. After the fiber has been dyed and fully rinsed, it can be “saddened” to Rusty Purple. If using fiber that has already dried, just soak it in water until it is thoroughly wetted through.

Fill a dye pot with hot tap water. Add 2% WOF iron powder* (ferrous sulfate) and mix well until the powder is fully dissolved.

Add the wetted fiber to the dyebath and quickly raise the heat to 170F.

Maintain temperature at 170F for 5 to 10 minutes. This is long enough to shift the color of fiber that is already dyed red with madder.

As soon as the fiber has achieved the desired depth of color, remove the dye pot from heat. When the fiber is cool enough to handle, remove with tongs and rinse well in warm water. Iron can make fibers feel coarse if left in contact for too long, so the goal is to get the saddened fiber rinsed as quickly as possible. This is more of an issue for wool than for cotton or silk, which are less liable to be damaged by iron.

When ready for the final rinse, rinse thoroughly with detergent as described in the recipe for “Turkish Red.”

Dispose of dyebath according to local regulations. Clean dye pot well. The iron may cause it to rust if left inside overnight. If any iron is not scrubbed out, it can accidentally “sadden” your next dye bath.

*CAUTION: Iron powder is an irritant and may be harmful if ingested. Please read your manufacturer’s safety sheet (MSDS) before using. Wear gloves, eye protection, and a mask while handling, and do not handle the “saddened” fiber with bare hands until it has been rinsed. Keep iron powder and dye baths containing iron powder away from children and pets. If you prefer not to use iron in its powdered form, it is possible to get the same “saddening” effect by making an iron solution from an old iron nail.

7. Recipe - Cold-Dyed Peach

Madder is one of several natural dyes that can be applied successfully without heat. It requires more patience than hot-dyeing, and may take several days of steeping to get darker reds. However, it can be useful if you are dyeing something that responds poorly to heat, or if you just want to conserve energy.

After following the recipe for Turkish Red, save the dyebath to use as an “exhaust bath.” Exhaust baths tend to produce slightly orangier or peachier colors than the original bath. If you don’t have an exhaust bath ready, you can get a similar effect by making a new dyebath with a weaker concentration of Wild Madder Extract. Try making a dye bath with 2% WOF to get soft pinks and peaches using the cold-dye method.

Check to see if there are any solid particles or precipitate in the dyebath: if so, filter it through a large coffee filter or cheese cloth. The particles can cause splotches on fibers that touch them. It will be more noticeable on woven fibers than on yarn.

Toss in some fibers that have been pre-mordanted with alum (even when cold-dyeing, madder requires alum to bond effectively).

Cover the dyebath and let steep for 24 hours. If you want, leave the dye pot outside in the sun to accelerate the process and take advantage of natural heat.

After 24 hours, check the color. It should be a soft peach. You can remove the fibers now, or stir them and then leave them for another 24 hours to let the color deepen.

After removing the fibers, rinse briefly in lukewarm water. Hang up to dry to help the color set. Make sure to hang up in a place where dripping dye won’t cause any damage.

When ready for the final rinse, rinse thoroughly with detergent as described in the recipe for Turkish Red.

Hang up to dry.

*All text and images are copyright of Shepherd Textiles, LLC. Do not reproduce without permission and attribution.