Indigo EZ™

Indigo EZ™

Prereduced Natural Indigo

Indigo EZ™ makes dyeing with indigo simple, fast, and fun. Indigo EZ™ is 100% natural Indian indigo (indigofera tinctoria) that has been partially reduced through organic fermentation so that it will dissolve quickly and easily in a standard reduction vat. It eliminates the need for hydrating indigo powder, making an initial stock solution, or long waits for reduction. Indigo EZ™ can get you dipping and dyeing in half an hour or less. Each bottle of Indigo EZ™ contains 50 grams of prereduced liquid indigo, and it will dye between 1 and 2 pounds of fiber to a dark or medium blue. Sold by the bottle, or as part of a kit together with 100 grams of calcium hydroxide and 150 grams of fructose sugar for making a 1-2-3 indigo vat.

1. Background on Indigo

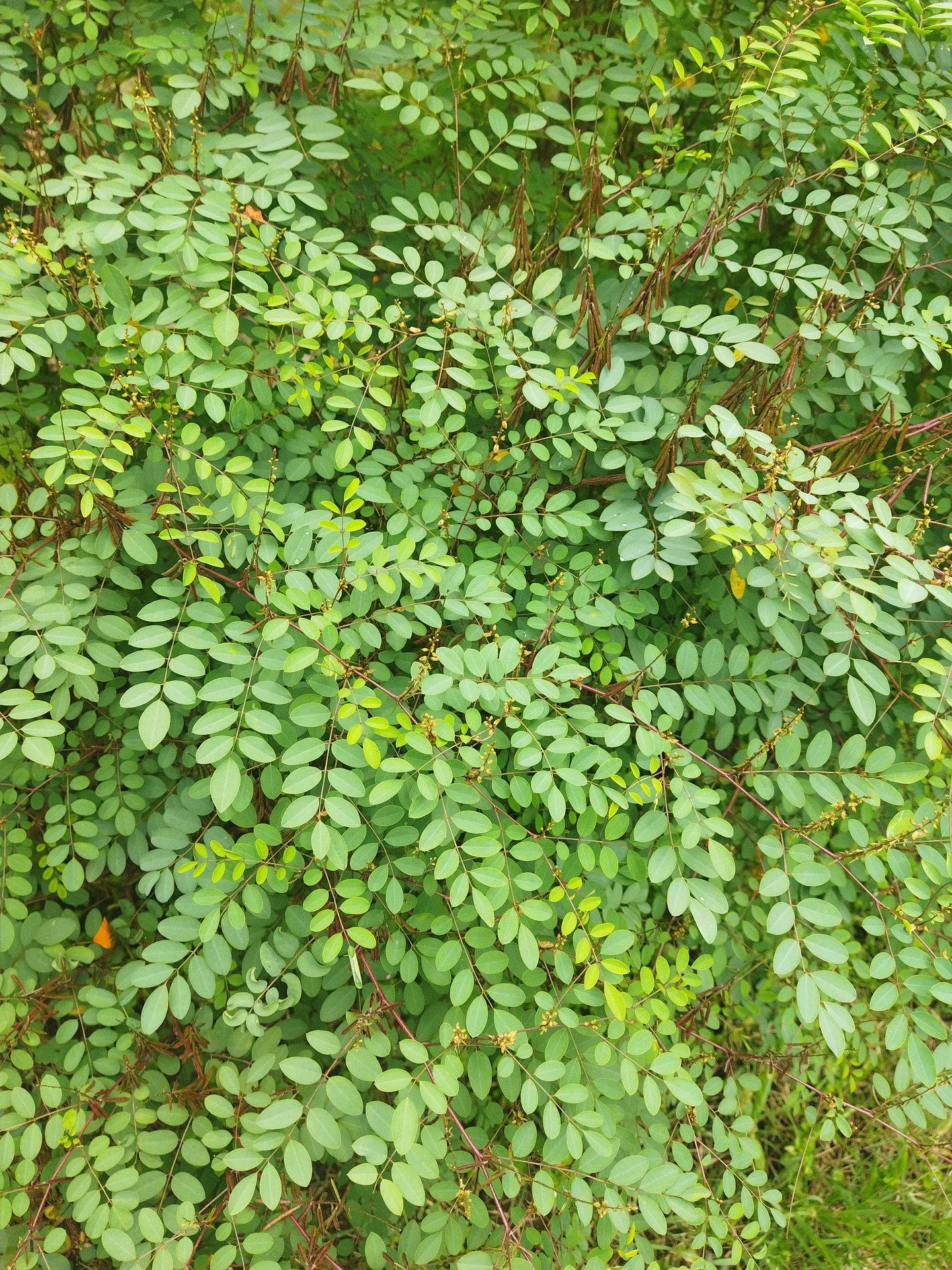

Indigo holds a special place among the natural dyes. It is nature’s strongest and most lightfast blue pigment, and it can produce beautiful shades ranging from soft sky blues to dark midnight blues. Indigo has been used for millenia to dye textiles: there is evidence that cloth was being dyed with indigo more than six thousand years ago in the Indus Valley, and its blue hues have been celebrated by cultures all across the world, from the batik of Indonesia to West African adire, Japanese shibori, and Hmong wax resist. For a time indigo was one of the world’s most important cash crops. rivalling even tobacco and cotton in importance, but the invention of synthetic indigo in the late 1800s caused the market for naturally grown indigo to collapse. Today most of the indigo used to dye blue jeans and other textiles is synthesized from petrochemicals like benzene, but natural indigo of high quality is still grown in places like India, Japan, and El Salvador.

Indigo is unique in terms of how it is applied to textiles. Most natural dyes, like madder and logwood, are mordant dyes. The pigments they contain bond at a molecular level with a metal ion like aluminum or iron, which in turn is bonded to the textile fiber. Applying mordant dyes is usually a simple matter of dissolving the color in a dye bath and heating it together with mordanted fiber. Indigo works very differently. It is not a mordant dye and it is completely insoluble in water, so it cannot be applied by simmering it in a hot dye bath. Instead, indigo must be applied by reducing it to a more soluble form, leuco-indigo, inside a reduction vat. A reduction vat is simply a vat of water that is reduced (the dissolved oxygen has been removed) and alkaline ( with a pH maintained between 9.5 and 11). Under these specific conditions, blue indigo will dissolve into colorless leuco-indigo. Textile fibers are soaked in the reduction vat and saturated with the dissolved leuco-indigo. When the fibers are removed from the vat, oxygen in the air converts the leuco-indigo back into blue indigo, and the dye precipitates directly onto the surface of the textile fibers. This unique chemistry gives indigo some advantages over other natural dyes: it does not require a mordant, it applies well to all textile fibers, and it is exceptionally fast to light. However, this same unique chemistry also makes indigo more challenging to apply. Building a successful reduction vat is a complex skill, and getting a poor or incomplete reduction can be discouraging for dyers who just want to dye something blue.

Indigo EZ™ Prereduced Natural Indigo was developed to make dyeing with indigo simpler, easier, and more fun. Indigo EZ™ is made from real, natural indigo grown and harvested in India. The indigo is extracted from the plant leaves and then reduced through organic fermentation (one of the most traditional methods of making an indigo vat) until it becomes a highly concentrated liquid that will finish reducing quickly and easily in any standard reduction vat. Indigo EZ™ makes it possible to get a vat set up and ready for dyeing in as little as half an hour. Please see our dyeing guide below for instructions for an easy 1-2-3 fructose vat, and get ready to start dyeing blue!

2. Safety Precautions

Indigo EZ™ contains highly concentrated liquid indigo. It may stain clothing, utensils, or skin. Stains on some surfaces may be permanent. Open carefully to avoid spills.

May cause skin irritation or eye irritation. Wear gloves and a mask while handling Indigo EZ™.

May be harmful if swallowed. Do not ingest.

Store this product out of reach of children. Store indigo-dyeing assistants like calcium hydroxide or thiourea dioxide out of reach of children as well. Use this product with adult supervision only.

Use only with pots, buckets, and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will also be used for food preparation.

For textile projects only.

FIRST AID: In case of skin contact or eye contact, wash for several minutes with cool water. In case of accidental ingestion, seek professional medical advice if you feel unwell.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

5-gallon bucket & lid. A standard 5-gallon bucket from a hardware store will make an indigo vat with one 50-gram jar of Indigo EZ™. Most plastic 5-gallon buckets are made of material that will withstand hot water, but if in doubt, check to make sure. You will also want a lid to cover the vat when it is not actively being used.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out of a deep bucket. Use tongs dedicated to dyeing, and not used for food preparation.

Rubber gloves. Wear rubber gloves while handling fibers and working them in the indigo vat. Get the heavy-duty kind that are easy to slip on and off, not the thin latex ones.

A mesh basket or wire frame. When leaving fibers in the vat for long dips, you will need to keep them from touching the sediment on the bottom. Some dyers like to use a mesh laundry basket suspended in the vat; other dyers put an upside-down pasta strainer at the bottom of the bucket, or make their own simple frame out of wire mesh.

Thermometer. To check the temperature of the water when building the vat — each vat has a specific temperature that optimizes the initial reduction.

Scale. To weigh out the ingredients.

Two plastic or glass cups. To weight out the ingredients.

PH strips. Optional, but can assist in troubleshooting a vat.

Fructose sugar. The reduction agent in organic vats. Other types of sugar like table sugar are not a substitute.

Calcium hydroxide. The alkaline agent in some vats. Also known as pickling lime or cal.

Soda ash. Sodium carbonate, or washing soda. Used to scour (clean) cotton and linen before dyeing.

Distilled white vinegar. Used to help clean the fibers after dyeing.

Vat Recipe

4. The 1-2-3 Fructose Vat

The 1-2-3 Fructose Vat, originally developed by Michael Garcia, is very popular with natural dyers because it uses fruit sugar as the reducing agent rather than industrial chemicals like hydrosulfite. The proportion of ingredients is also very easy to remember: one part indigo, two parts calcium hydroxide, and three parts fructose sugar. A 1-2-3 Fructose Vat is simple to build with Indigo EZ™ and it can reduce and be ready for dyeing in as little as 15 or 20 minutes. This vat can be used to dye any natural fiber. It is especially well-suited for plant fibers like cotton and linen and produces very rich, deep blues. The large quantity of calcium hydroxide used in this style of vat can be a bit rough on woolen fibers, but if they are treated carefully (and quickly neutralized with vinegar after dyeing) they will remain perfectly soft and develop gorgeous shades of blue.

Wool yarn, three 30-minute dips

Silk habotai, two 3-minute dips

Cotton shirt, three 3-minute dips

Linen scarf, three 10-minute dips

Cotton shirt, three 30-minute dips

Linen scarf, five 10-minute dips

Prepare the fibers to be dyed by scouring (cleaning) them well. Cotton and linen should be simmered in a dye pot for an hour with a little soda ash (about 1 gram of soda ash per pound of fiber), then rinsed well as soon as the fibers have cooled down enough to handle safely. Wool and silk should be heated to 160°F for an hour with a teaspoon of pH-neutral detergent like Synthrapol, then rinsed well in warm water as soon as they have cooled down enough to handle safely. The fibers should be clean and wetted through before being dyed in the indigo vat.

Once the fibers are ready, measure out the vat ingredients. For one 50-gram bottle of Indigo EZ™, you will need to weigh out 100 grams of calcium hydroxide and 150 grams of fructose sugar.

Heat 1 gallon of soft or distilled water to 135°F. Gently pour into an empty 5-gallon bucket, avoiding too much splashing or bubbles.

Sprinkle the calcium hydroxide onto the water, stirring gently to break up any clumps. Continue stirring for two or three minutes to make sure the calcium hydroxide is fully and evenly dispersed. Once you stop stirring it will begin to settle, which is fine — calcium hydroxide does not really dissolve in water, but mostly just disperses in it.

Heat the remaining 3 gallons of soft or distilled water to 135°F and pour into the bucket.

Stir the liquid in the bucket gently in a clockwise or counterclockwise direction to create a vortex, being careful not to splash the water or introduce air bubbles. Pour an entire 50-gram bottle of Indigo EZ™ into the vat. Hold the bottle as close to the surface of the water as possible when pouring it in, to reduce air contact.

Continue stirring gently until the indigo is fully mixed into the vat and the liquid has a uniform dark blue-brown color. Stop stirring and let the vat settle for 2 minutes.

After 2 minutes have passed, start stirring the vat again in a clockwise or counterclockwise direction to create a vortex, being careful not to splash the water or introduce air bubbles. Sprinkle the fructose sugar into the vat and stir until it is incorporated.

Cover the vat loosely with a lid and wait 20 minutes for the vat to reduce and settle.

After 20 minutes, check the vat. There should be a small “flower” in the center (bubbles colored blue from oxidized indigo) and a thin metallic sheen on the surface. Looking directly down into the vat it will like appear dark and opaque, but if you dip a spoon in it, the liquid in the spoon should be a clear dark yellow or brown color (there may also be a few blue or green flecks from the oxidized indigo which rests on the surface of the vat). Once the liquid is clear, the vat is ready for dipping.

[Troubleshooting] Sometimes the vat liquid will appear dark yellow or brown but will not be transparent. Instead it may appear cloudy and full of little white particles, almost like a thick miso soup. If so, give the vat another good stir to reincorporate any ingredients that have settled on the bottom. Cover it and allow 10 more minutes to reduce; after 10 minutes the cloudiness should be reduced and the vat should be ready for dyeing. The white “miso soup” sediment floating in the vat is most likely a degradation product of fructose sugar, such as calcium fructate or calcium saccharate. These are most likely to form if the vat is too hot (any temperature above 130°F can encourage the formation of calcium-sugar compounds in an alkaline vat, but they become most obvious if the vat is heated past 150°F). These compounds are inert and harmless, but should be avoided if possible, because they waste the reducing power of the fructose sugar. This is why we recommend not heating a fructose vat past 135°F.

5. Dipping

Indigo is applied by dipping fibers into the reduction vat, letting them soak up the dissolved leuco-indigo, and then taking them out and letting them oxidize until the leuco-indigo turns blue. Afterwards, this dipping and oxidizing process can be repeated as many times as necessary until the blue is as dark as desired. Different indigo dyers have different preferences for how long to dip the fibers — you may see recommendations for dips lasting anywhere from 3 minutes to 30 minutes or more. Note that if you are aiming for lighter shades of blue, it is easiest to get them with a vat that is already partly used up, rather than trying to get a light shade by doing a very short dip in a fresh vat (which will often come out looking uneven). Items that will be dark blue should be dyed first, and items that will be lighter should be dyed closer to the end of an indigo session.

When the liquid in the vat is a dark yellow or amber color, the vat is reduced and ready for dyeing.

Gently place the scoured, wetted fibers into the vat and work them around while wearing gloves.

When first removed, the fibers will be yellow or brownish but will quickly start oxidizing to blue.

Before any fibers are dipped in the vat, they should be very well scoured (cleaned) and fully wetted through.

Wearing rubber gloves, gently slide the fibers beneath the surface of the vat. Use your hands to move the fibers around for a minute or two under the surface, squeezing and massaging them to make sure the liquid penetrates the fibers evenly. Try not to splash the water or otherwise draw any air into the vat, and be careful not to let the fibers touch the sediment at the bottom of the vat.

Leave the fibers in the vat for anywhere from 3 minutes to 30 minutes. The ideal time will depend on a variety of factors, such as the type of fiber and how densely it is spun or woven. Ten minutes per dip is usually a good starting point. If you are doing a short dip (say, 3 or 4 minutes) you may wish to simply hold the fibers under the surface of the vat by hand. If you are doing a long dip, you will need to leave the fibers in the vat without letting them touch the bottom. Some dyers like to put the fibers in a mesh bag and suspend it in the vat; other dyers put some sort of frame in the vat (for example, an upside-down pasta strainer) to keep the fibers off the bottom. If needed, you can make your own frame by bending a small piece of wire fence or wire mesh so it will fill the bottom of the bucket.

If you are leaving the fibers in the vat for a long dip, be sure there are no bubbles trapped under them and that none of the fibers are poking above the surface; otherwise you may end up with darker or lighter spots. When doing a very long dip, you may also wish to gently move the fibers around under the surface of the vat every 10 minutes or so to help them dye more evenly, although you can skip this if you do not mind a slightly uneven look.

When the dip is finished, slowly and gently remove the fibers from the vat. If possible, try to squeeze some of the vat liquid back into the vat just below the surface as you are pulling the fiber out. However, try not to make any splashes or let liquid drip back into the vat from higher up. The goal is to keep as much of the vat liquid in the vat as possible without introducing any air into it — otherwise the vat will eventually empty of liquid to work with.

[Optional] Set aside a separate bucket of clean, lukewarm water. As soon as you have removed the fibers from the indigo vat, plunge them in this bucket of water and stir them around very briefly — for no more than 5 seconds — and then pull them out and hang them up to oxidize. This quick plunge after every dip will help to remove organic sediment and poorly bonded indigo from the surface of the fibers. This will help to prevent crocking later on, and it will make the final rinsing of the fibers much easier. This step is optional, but highly recommended.

Hang the fibers up to oxidize somewhere where dripping indigo will not cause any damage. The fibers will change from a yellow or green shade to blue as air causes the dissolved leuco-indigo to oxidize into indigo. Let the fibers oxidize for at least 20 minutes. However, the exact length of time necessary will depend on how densely the fibers are spun or woven; some thick fabrics may need an hour to oxidize all the way through.

Once the fibers have oxidized, you can either dip them again to get a darker shade, or proceed to a final rinsing. However, note that the fibers will end up looking several shades lighter after they have been rinsed and dried, so you may want to keep dipping until the fibers look a bit darker than the color you are actually aiming for.

6. Rinsing

Indigo is notorious for crocking, or what is known in fiber terminology as “poor fastness to rubbing.” Since indigo works by coating the outer surface of textile fibers, it is more liable to rub off than mordant dyes. Indeed, even in perfectly controlled laboratory conditions, indigo only scores a 2 out of 5 on most tests of rubfastness. Crocking indigo is not fun to work with and it can stain your hands, tools, and furniture. Proper rinsing techniques can vastly improve indigo’s fastness to rubbing, and brighten the blue as well. We strongly recommend doing the whole sequence described here whenever dyeing fiber with indigo — initial rinse, vinegar soak, hot soaping, and final rinse — which takes time but will save a lot of grief in the long run.

When you are finished dipping and ready to wash the fibers, the first step is an initial rinse to get most of the organic sediment and unbonded indigo off the surface of the fibers. Rinse the fibers very well in 2 or 3 changes of lukewarm water, without any detergent, until the rinse water runs noticeably clearer. However, do not worry about getting them 100% clean at this stage. Small amounts of indigo will continue to bleed into the rinse water (and onto your hands) until after the vinegar soak and the hot soaping.

The second step is a vinegar soak. Fill a bucket with enough water for the fibers to move around freely. Add distilled white vinegar (we use about 1/8 cup vinegar per gallon of soaking water) and mix well. Gently place the fibers in the vinegar solution and let soak for 20 or 30 minutes. The vinegar soak has three benefits. In the first place, it is said to brighten the blue shade and make it more intense. Second, the acid in the vinegar helps to neutralize the fibers after they have been soaking in a very alkaline indigo vat. Finally, the acetic acid in the vinegar helps to remove any calcium sediment on the fibers by converting it to calcium acetate, which is highly soluble in water and easily washes off. Removing this calcium sediment will help to prevent the color from crocking. After a 20 or 30 minute soak in the vinegar solution, remove and rinse the fibers well in lukewarm water.

The next step is a hot soaping. Fill a dye pot with enough lukewarm water for the fibers to move around freely. Add 1 teaspoon of pH-neutral detergent (we use Synthrapol), plus another teaspoon for each additional pound of fiber beyond the first. Heat the hot soap bath to 180°F for wool and silk, or a very gentle simmer for cotton and linen. Maintain this heat for 30 minutes, stirring the fibers occasionally. The water in the hot soap bath will get progressively bluer as poorly bonded indigo precipitates off the surface of the fibers. After 30 minutes, turn off the heat and allow the soap bath to cool until the fibers can safely be handled.

The last step is a final rinse. Remove the fibers from the soap bath and rinse well in warm water. Be careful if wringing them (even in the very best of circumstances indigo has poor fastness to rubbing when wet, so well-rinsed fibers might still crock on your hands if you try to wring them too hard). Rinse until the water runs clear.

Hang up to dry somewhere out of direct sunlight.

[Troubleshooting] This treatment is usually enough to successfully rinse indigo-dyed fibers. Gently handling them while they are still wet (not wringing them hard) should not transfer noticeable color to your fingers. Once dry, they should have good fastness to rubbing, although they should still be treated with caution. Do not wash them with other fabrics (and avoid sitting on light-colored furniture!) until they have been washed a few more times. However, if after the rinsing process the fibers are still bleeding badly, you may want to repeat the hot soaping and final rinse. If the fibers simply refuse to rinse clean, the most likely culprits are an incomplete scouring (the fibers were not scoured clean before they were dyed), excessively long dips, or working with a vat that had fallen almost totally out of reduction.

*All text and images are copyright of Shepherd Textiles, LLC. Do not reproduce without permission and attribution.