ALUMINUM FORMATE PRO

Deep colors on cotton, no heat required

Aluminum Formate Pro is a powerful new aluminum mordant intended specifically for dyeing cotton and linen. It contains a highly concentrated form of aluminum formate which efficiently bonds with plant tannins, even at room temperature. When applied cold to cotton or linen that has been treated with a tannin like Oak Gall Extract or Chestnut Extract, it will mordant the fibers deeply and evenly and produce bright colors after dyeing. Aluminum Formate Pro is an excellent choice for dyers looking to get consistently good results on plant-based fibers. Use at 10% weight-of-fabric (WOF) on cotton or linen pre-treated with a tannin. Sold in jars of 100 grams.

1. Background on Aluminum Formate Pro

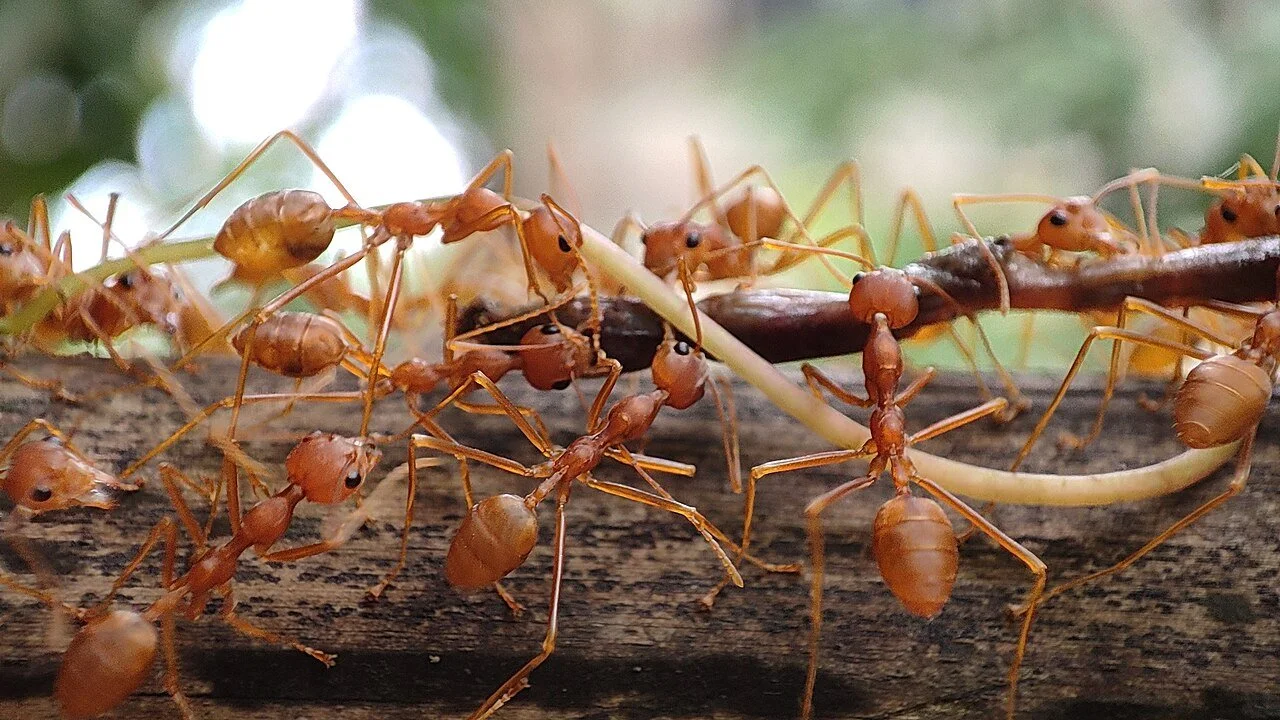

Aluminum Formate Pro is an aluminum mordant for cotton and linen that delivers deep and consistent results when applied with the assistance of a tannin. Aluminum formate is a metal salt that forms when aluminum reacts with formic acid, an organic acid commonly found in nature, perhaps most famously in the venom of certain ants (hence the name “formic,” which refers to the ant family formicidae). Aluminum Formate Pro has the very valuable property of complexing with tannins at room temperature. Unlike traditional aluminum mordants, it will mordant cotton or linen that has been pretreated with a tannin like oak galls or sumac even when applied cold. This is an advantage not just because it reduces energy use, but because when it is applied cold in this way it tends to give strong, consistent, and level (even) results. Aluminum Formate Pro works well with all the hydrolysable (gallic and ellagic) tannins, including Oak Gall Extract, Oak Gall Light, Sumac Extract, Chestnut Extract, Myrobalan Extract, and Pomegranate Extract. To use it, simply place plant fibers saturated with tannin matter in a room-temperature bath of Aluminum Formate Pro and let the fibers steep for two hours. That’s it! A short chalk bath may be used afterward to precipitate out excess mordant, and then the fibers are rinsed well and dyed. Note that we do not recommend Aluminum Formate Pro as a mordant on woolen fibers, since without the tannin fixation used with cotton and linen the color will be prone to crocking. Aluminum Formate Pro is an exciting new development in natural dyeing and it makes getting bright colors on cotton a breeze.

2. Safety Precautions

WARNING: May cause skin, eye, or respiratory irritation. Harmful if swallowed. Wear gloves, a mask, and eye protection while handling. Do not ingest. Avoid inhaling dust.

FIRST AID: In case of skin or eye contact, rinse with water for a few minutes. If discomfort persists, seek medical advice. If swallowed, seek immediate medical attention.

For textile projects only.

Open carefully to avoid spills. If a spill occurs, quickly wipe up with a paper towel or rag.

Aluminum Formate Pro should not be applied to fibers with heat, as heating may produce irritating acidic fumes.

Use this product only with pots and utensils that are dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that are also used for food preparation.

Store out of reach of children. To prevent accidental ingestion, all dye baths and mordant baths made while dyeing should also be stored out of reach of children and pets. Use only with adult supervision.

SDS available on request.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot or plastic bucket. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely. A stainless steel stock pot usually works well. Since aluminum acetate does not need to be applied at a boiling heat, a heavy-duty plastic bucket can be used instead.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it is rinsed.

Calcium carbonate (chalk). Chalk may be used to precipitate any excess mordant out of the fibers.

Candy thermometer. A cheap candy thermometer that clips to the side of the dye pot will make it easier to track the temperature.

Scale. Use a scale to weigh out the mordant and the chalk.

Tannin. Aluminum Formate Pro should be applied to cotton or linen that has been treated with a tannin like Sumac Extract or Oak Gall Light.

Instructions

5. Mordanting Cotton & Linen

Aluminum Formate Pro is applied to cotton and linen fibers with the assistance of a tannin. The fibers are first saturated in the tannin solution overnight, then gently wrung out and placed in a room temperature bath with 10% weight-of-fabric (WOF) of Aluminum Formate Pro and left to steep for two hours. Afterwards, the fibers may be briefly placed in a fixing bath to precipitate out any excess mordant, then they are washed well and dyed. By combining different tannins and different dyes, countless shades of color can be applied to cotton and linen. Some examples are pictured below.

10% Oak Gall Light + 6% French Weld Extract

10% Sumac Extract + 2.5% Onion Peel Extract

12% Chestnut Extract (no additional dye)

10% Oak Gall Light + 3% Royal Logwood Ext.

12% Chestnut Extract + 15% Cutch Extract

10% Oak Gall Light + 8% Peruvian Cochineal

12% Myrobalan Extract + 80% Madder Root

10% Sumac Extract + 12% Coreopsis Extract

Scour (clean) the cotton or linen fibers well. Fill a dye pot with enough warm water for the fibers to move around freely. Add 1 gram of soda ash (sodium carbonate), plus 1 gram for each additional pound of fiber. Add the fibers and raise the heat to a very gentle simmer. Simmer the fibers for one hour, stirring occasionally. After an hour, remove from the heat. When cool enough to handle safely, rinse well with warm water until the water runs clear.

Prepare the fibers by treating them with a tannin like Sumac Extract, Oak Gall Extract, Oak Gall Extract Light, Myrobalan Extract, Pomegranate Extract, or Chestnut Extract. Dissolve 10-12% weight-of-fabric (WOF) of the tannin extract into a dye pot with just enough warm water to cover the fibers [see Note 1]. Add the cotton or linen and then bring the tannin bath just to a boil. Immediately remove the pot from the heat, cover it, and let the fibers steep overnight. Stir them occasionally so that they absorb the tannin evenly. Before going to bed, make sure that there are no bubbles trapped underneath the fibers and that the fibers are fully submerged.

When ready to proceed the next day, lift the fibers out of the tannin bath and gently squeeze excess liquid out (just enough so that they are not dripping). Do not rinse them. The tannin bath may be reused so long as it is not cloudy, although it may need to be topped off with more of the tannin extract.

Fill a dye pot or plastic bucket with enough soft or distilled water for the fibers to move around freely. The water should be room temperature or very slightly lukewarm, around 80-90°F (27-32°C).

Weigh out 10% weight-of-fabric (WOF) of Aluminum Formate Pro. Add to the mordant bath and mix well until fully dissolved. The mordant bath will turn a milky white color.

Gently add your tannin-treated cotton or linen fibers to the mordant bath. Wearing rubber gloves, work the fibers in the liquid to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath.

Cover the pot or bucket and let the fibers steep for 2 hours. Stir the fibers a few times while they are steeping to make sure they mordant evenly. After 2 hours, the cotton or linen will be thoroughly mordanted with aluminum (although the fibers may not look any different at this stage, especially if you are using a clear tannin).

[Optional] This step is optional but recommended. Prepare a chalk fixing bath: fill a bucket or dye pot with hot tap water (around 110°F/43°C). Measure out 2 grams of chalk (calcium carbonate) per liter of water. Add the chalk and mix well until dispersed. Wearing gloves, remove the cotton or linen from the mordant bath, gently squeeze out, then place it in the chalk fixing bath. Let the fibers steep in the fixing bath for 5 minutes [see NOTE 2]. After five minutes most of the excess mordant will be precipitated out of the fibers and the fibers can be removed and rinsed.

Rinse the fibers. Wearing gloves, remove the cotton or linen from the mordant bath or fixing bath (if used) and rinse well until the water runs clear. It is important to rinse out excess mordant and tannin at this stage, because otherwise it will cause trouble later on in the dye bath (some of the excess mordant may bleed out into the dye bath and waste dye, and some of it may fix superficially to the surface of the fibers and make them tedious to rinse).

When the cotton or linen has been thoroughly rinsed, proceed directly to dyeing. The swatches above show cotton tshirts mordanted and dyed with Aluminum Formate Pro, using different combinations of tannins and dyes [see Note 3].

NOTE 1. The amount of aluminum that the cotton or linen will absorb during the mordanting step will depend entirely on how much tannin is soaked into the fibers. A more concentrated tannin bath will result in more mordant absorption, and potentially darker colors after dyeing. If you need especially dark colors, do not calculate the amount of tannin based on the weight of the fibers (e.g., 10% WOF). Instead, make a concentrated tannin bath using 5 or 10 grams of tannin extract per liter of water.

NOTE 2. The purpose of this fixing bath is to precipitate out any excess aluminum mordant that is not firmly attached to the fibers. There will always be some portion of the aluminum that is not bound by the tannins, and it can be removed by precipitating it with a weak alkali like chalk. Otherwise, it may cause issues later on. Superficially attached mordant is liable to rub off the surface of the fibers, which can result in bleeding and crocking after dyeing is complete. It is much easier to remove this excess mordant with a quick fixing bath, rather than to try and rinse it out later. With some dyes (especially dyes with lots of tannins, like cutch or raw madder root) the fixing bath might not be necessary because the tannins in the dye itself can fix the excess mordant. However, when working with highly purified dye extracts like Wild Madder Extract or Royal Logwood Extract, the fixing bath will help in preventing later bleeding and making the cotton or linen easier to rinse.

NOTE 3. Different tannins have different advantages. In general, oak gall tannins will fix the most mordant and result in the darkest, most opaque colors (especially on thin fabrics like tshirts). Sumac tannins are noted for producing very clear, bright shades, but the color will not be quite as dark and opaque. Chestnut and myrobalan will add a distinctive brownish note that can complement dyes like madder and cutch.

*All text and images are copyright of Shepherd Textiles, LLC. Do not reproduce without permission and attribution.