Campeche Blue™

A Guide to Campeche Blue

Shepherd Textiles Campeche Blue natural dye is made from the wood of the logwood tree, hematoxylin campechianum. The pigment in logwood, hematein, can produce a variety of shades of purple, blue, and black depending on how it is treated. Through careful control of oxidation during the extraction process, we’ve created a logwood extract that easily dyes blue on all natural fibers. Campeche Blue works on wool, cotton, and silk using between 2% and 8% weight-of-fabric depending on the recipe. Made in the USA. Campeche Blue is a trademark of Shepherd Textiles LLC. Patent pending.

1. Background on Logwood

Campeche Blue is made from the wood of the logwood tree, hematoxylin campechianum. Logwood is a shrubby tree in the legume family that is native to the tropical Americas, especially the lowland rainforests of the Yucatán peninsula where it grows well in soggy soil. Spanish colonists learned about the dye in the late 16th century from their new Mayan subjects, who had used it for centuries to dye their cotton clothing blue, purple, and black (De la Garza 1983:74). The Spanish Crown recognized the commercial value of such a versatile new dyestuff, and commanded that massive quantities be shipped every year to Seville. Logwood got its Latin appelation campechianum from the port of Campeche in Mexico, which was the major port of export throughout the 16th and 17th centuries. European dyers quickly learned to appreciate the strength and versatility of logwood, so much so that it began to compete with the northern European woad industry. In a well-known historical episode, the English Parliament of 1581 actually banned the trade in logwood on the grounds that it was excessively fugitive (“deceitful”) (Iqbal 2013:286). It is true that logwood is nowhere near as fast to light as indigo or woad, but its fastness is about on par with many other natural dyes in use at the time. Modern historiography suggests that the ban had more to do with protecting England’s woad growers from Spanish competition rather than any real concern about fading colors (ibid). Indeed, the ban was quickly relaxed once England developed its own logwood plantations in Jamaica about a century later.

Logwood contains a natural compound called hematoxylin that is colorless in its pure state. However, it quickly oxidizes on contact with oxygen or chemical oxidants into hematein, a reddish-purple pigment. Hematein is one of the most versatile and potent of all known dyestuffs. It easily bonds with metal mordants to form different color lakes. Alum produces purple; tin violet; copper dark blue; and iron gray/black. It is also extremely sensitive to all the variables in the dye bath, including temperature, pH, and the concentration of dissolved minerals like magnesium and calcium. This extreme sensitivity makes it possible to produce a great variety of shades, although it can also make it difficult to reproduce a particular shade of color consistently.

Campeche Blue is a special logwood extract that Shepherd Textiles developed specifically for textile dyers. It is formulated to make it easy to get good blue shades on wool, cotton, and silk, using between 2% and 8% weight-of-fabric. However, the methods required vary depending on the fiber type, as described below. The dye should always be added to the dye bath cold to prevent the hematein from precipitating prematurely, and the bath should be heated very gradually to get a level (even) color. It is best to put the powder in a tea bag or muslin dye bag, as the particles of dye will not completely dissolve until the dye bath is very hot, and keeping them in a bag will prevent particles of dye from causing dark speckles on woven fabrics. The dye bag should, however, be moved around so it does not rest on the fiber for too long. The end result is a series of beautiful blue shades without the need for a reduction vat.

The Battle of the Blues

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Contains natural hematoxylin. May cause skin irritation. May cause eye irritation. May cause respiratory irritation. Harmful if swallowed.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust. Work in a well-ventilated space. Wear mask if necessary to avoid inhaling powder.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Campeche Blue powder, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling Campeche Blue powder and mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Chalk (calcium carbonate). Used to control pH in several recipes. Available online, often from beer brewing suppliers.

Tea bags/muslin dye bags. Campeche Blue powder should be put in a tea bag or muslin dye bag to prevent speckles on the dyed fiber.

4. Preparation: Mordanting

The pigment in logwood, hematein, is extremely sensitive to just about every variable in the dyebath, including time, temperature, pH, fiber type, and mordant. Different strategies are required to get good blues on different fibers. For wool, the most beautiful blue shades develop on an alum mordant. Copper and iron are more commonly used with cotton and silk. The following basic mordanting techniques will give good results with Campeche Blue. However, note that some recipes use alternate methods.

For woolen fibers: Mordant with 5% alum and 5.5% cream of tartar.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.5 to calculate the amount of alum you will need, and 0.55 to calculate the amount of cream of tartar.

Fill your dye pot with enough hot tap water for your fibers to move around freely.

Weigh out the correct amount of cream of tartar and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Next, weight out the correct amount of alum and add it to the dye pot. Mix until well dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180°F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180°F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. Otherwise, an uneven dye job may result.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results when dyeing thick yarn or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers very well in two or three changes of lukewarm water. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For silk: Mordant with 5% copper sulfate or 5% ferrous sulfate.

Follow the directions for mordanting wool described above. However, use 5% copper sulfate or 5% ferrous sulfate rather than alum (depending on the recipe). Omit the cream of tartar, as it is not necessary when mordanting silk. After heating for an hour, let the silk cool down to room temperature in the mordant bath, then remove and rinse.

For cellulose fibers (cotton, linen, etc.): Tan and mordant with 5% copper sulfate or 5% ferrous sulfate.

Campeche Blue can be applied to cotton without premordanting (see Section 7: Vat Blue). However, for other recipes require that the cotton be tanned and then mordanted with copper or iron.

Scour (clean) the cotton by adding 1 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with just enough hot water for your fibers to move around freely - the more concentrated the tannin bath, the stronger the results will be. Dissolve 20% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they can bond to the mordant..

Prepare a mordant bath using 5% weight-of-fabric of copper sulfate or ferrous sulfate, depending on the recipe.: fill a pot with enough warm water for your cotton to move around freely. Add 5% copper sulfate and mix well until fully dissolved.

Heat the mordant bath to 160°F, place the cotton in it, and raise the heat to 190°F. Maintain for 30 minutes, stirring occcasionally to make sure the fibers mordant evenly. The cotton should turn a light or medium brown shade. After thirty minutes, remove the pot from heat. When cool enough to handle safely, remove fibers and rinse well in lukewarm water.

The Recipes

6. Recipe: Indigo Blue on Woolens

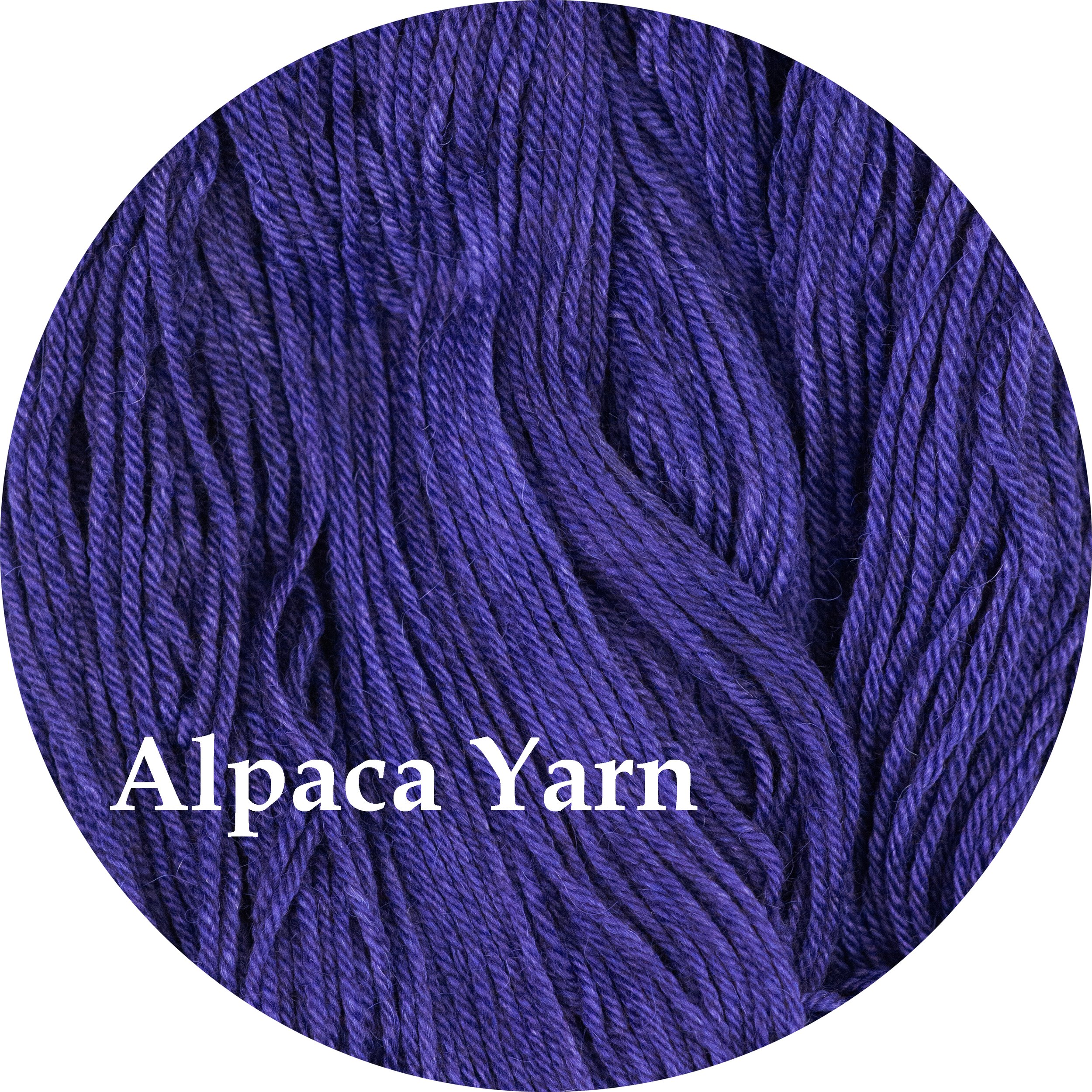

Campeche Blue produces a gorgeous blue on wool mordanted with alum. It is deeply saturated and has that hint of purple “bloom” that is normally obtained only from good natural indigo. In fact, when freshly dyed, it very much resembles a dark indigo blue. However, it is not as lightfast as indigo, so the dyed good should not be stored in direct sunlight. This recipe works on woolen fibers (sheep’s wool, alpaca, probably also mohair and cashmere) but not on cotton or silk.

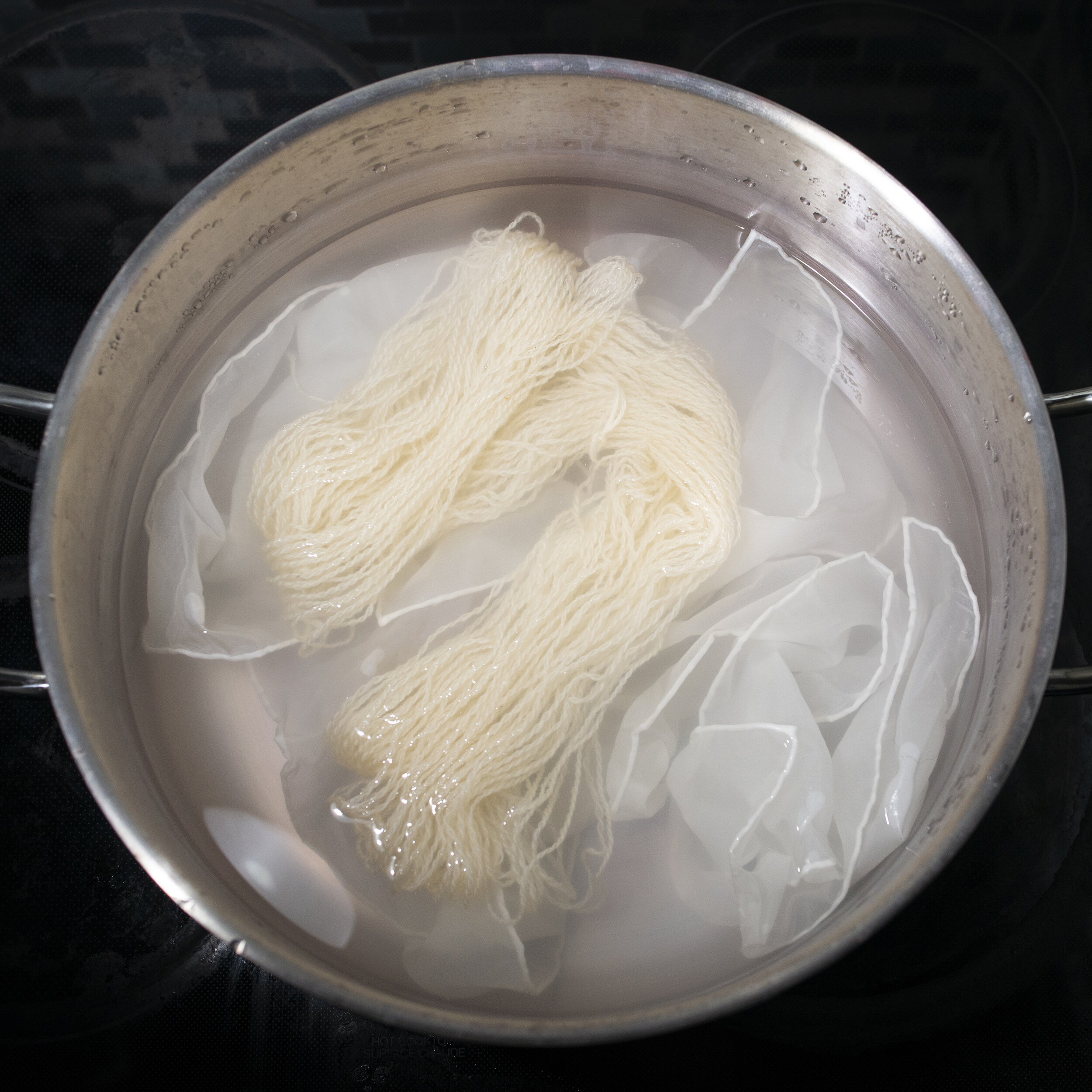

Fill your dye pot with enough cool water (no more than 80°F) for your wool to move around freely.

Weigh out 4% weight-of-fabric of Campeche Blue powder. Place it in a tea bag or muslin dye bag, tie it shut, then put the bag in the cold dye bath. If you are dyeing fewer than 2 ounces of wool, add 1 gram of chalk (calcium carbonate) to the dye bath at the same time.

Let the bag of dye soak for 20 minutes, stirring occasionally. The dye bath should change from a milky white to a dark violet color.

After 20 minutes, add your wetted, alum-mordanted wool to the dye bath*. Do not remove the dye bag - leave it in throughout the dyeing process. However, move it around regularly so it does not rest on the fiber too long, otherwise a a dark spot may result.

Raise the heat gradually to 180°F - it should take at least 15 or 20 minutes. Stir regularly to make sure the wool dyes evenly; otherwise resists (under-dyed spots) may form wherever there are folds, wrinkles, or ties around the wool.

Maintain the heat at 180°F for 45 minutes. After 45 minutes, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove and rinse well in lukewarm water with a few drops of a PH-neutral detergent like Synthrapol, which is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Campeche Blue will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

*NOTE: The wool should be rinsed very well after mordanting so that it does not introduce extra acid (from the alum and cream of tartar) into the dye bath. Too much extra acid can shift the color from blue back to purple. It should not be too difficult to rinse the acid out of yarn - two or three long rinses in lukewarm water should be sufficient. However, if you are mordanting a densely woven wool fabric, extra alum and tartar can easily get caught inside the fabric. If not thoroughly rinsed, these will slowly release as the dye bath heats up and eventually shift the color toward a reddish-purple. If your wool starts out looking blue after the first 20 minutes of dyeing, then looks red-purple by the end, unrinsed mordant and tartar is probably the culprit.

VARIATIONS: Use twice as much Campeche Blue (8%) for a very dark midnight blue. Lighter blues can also be dyed by using 1% or 2% weight-of-fabric of Campeche Blue. However, when dyeing lighter shades, be sure to add 1 gram of chalk (calcium carbonate) per gallon of water in the dye bath - otherwise you may end up with lavender.

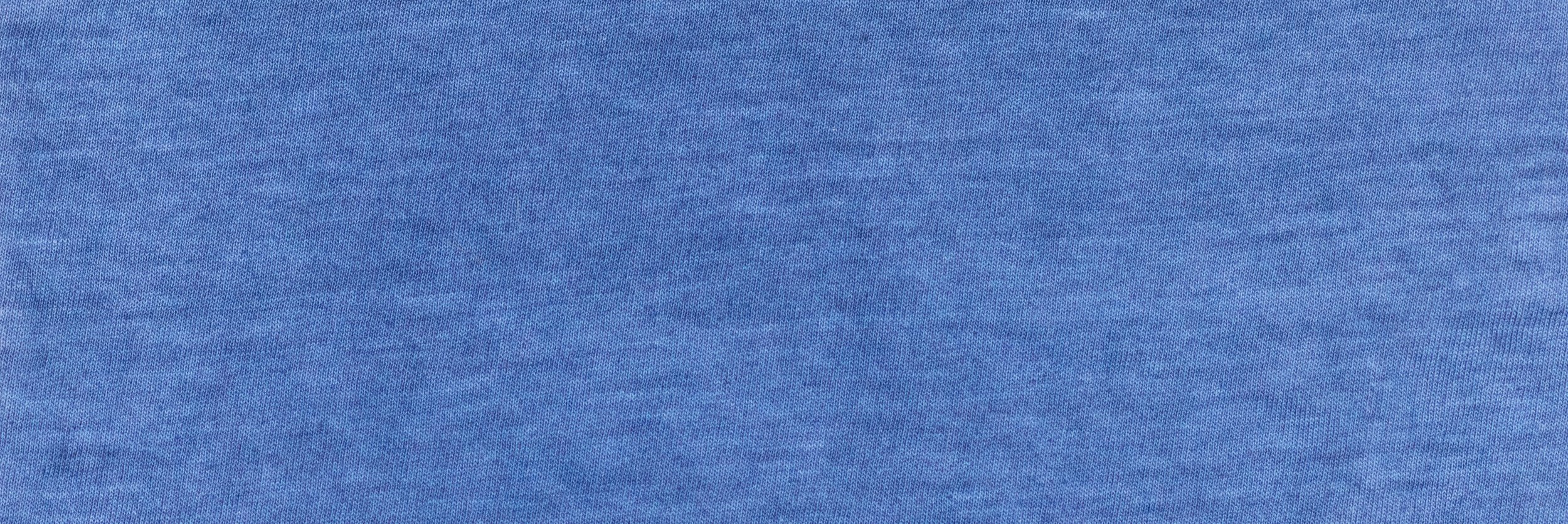

5. Recipe: Vat Blue on Cotton

This is a quick and easy recipe to get a bright, light blue on cotton. The dye, the mordant, and the cotton are simply heated together in a single bath at a relatively low temperature. According to Hummel (1885:323), this method was occasionally used as an alternative to vat blue (indigo blue) on cotton. However, because the mordant is not fixed to the cotton by means of a tannin, the color is not very fast to light. This recipe is probably best reserved for textiles that can be stored out of sunlight, or re-dyed when the color fades. It gives especially nice results on t-shirt cotton.

Fill your dye pot with enough cool water (no more than 80°F) for your cotton to move around freely.

Weigh out 8% weight-of-fabric of Campeche Blue powder. Place it in a tea bag or muslin dye bag, tie it shut, then put the bag in the cold dye bath. Let it soak for 20 or 30 minutes. The dye bath should turn a dark violet color.

When you are ready to start dyeing, measure out 1% weight-of-fabric of copper sulfate. Add to the dye bath and mix well until dissolved. The bath should quickly turn dark blue.

Add your unmordanted (but scoured and wetted) cotton fibers to the dye bath.

Raise the heat very gradually to 140°F - it should take at least 15 minutes. Maintain the heat at 140°F for 30 minutes, being careful not to let the bath get too much hotter. Stir occasionally to make sure the cotton dyes evenly.

After 30 minutes of dyeing, turn off the heat and allow the cotton to cool.

When the cotton is cool enough to handle safely, remove and rinse well in lukewarm water with a few drops of a PH-neutral detergent like Synthrapol, which is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Campeche Blue will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

NOTE: Logwood is extremely sensitive to small changes in the dyeing process, and you can get slightly different blue shades by using a little more or a little less Campeche Blue powder, dyeing at a slightly higher or lower temperature, dyeing for a longer or shorter period of time, or using a tiny bit more or less copper. However, make sure to keep detailed notes of all those variables if you ever want to recreate the same shade of blue in the future.

7. Recipe: Slate Blue

Traditionally, logwood was dyed on an iron mordant in order to get black. However, a logwood black is really just an extremely dark gray-blue. Victorian dyers would add a little yellow, in the form of weld or persian berries, to balance out that blue hue and make their blacks appear more neutral. This recipe uses a slightly smaller concentration of logwood (and omits the extra yellow) to emphasize the natural gray-blue of logwood on iron. It produces nice results on wool and on very white fibers like t-shirt cotton and silk satin. On fibers with a strong yellow tint, like unbleached tussah silk, the result is more of a gray shade.

[Preparation] Mordant fibers with iron as described in Section 4. For wool fibers, use 8% ferrous sulfate and 10% cream of tartar instead alum; be sure to dissolve the cream of tartar in the mordant bath first before adding the ferrous sulfate.

Fill your dye pot with enough cool water (no more than 90°F) for your fibers to move around freely.

Weigh out 2% weight-of-fabric of Campeche Blue powder (for wool and silk) or 5% (for cotton). Place it in a tea bag or muslin dye bag, tie it shut, then put the bag in the cold dye bath. Let it soak for 20 or 30 minutes. The dye bath should turn a dark violet color.

Add your wetted, iron-mordanted fibers to the dye bath.

Raise the heat gradually to 180°F , and maintain this heat for 30 minutes. Stir regularly to make sure the fibers dye evenly.

After 30 minutes of dyeing, turn off the heat and allow the fibers to cool.

When the fibers are cool enough to handle safely, remove and rinse well in lukewarm water with a few drops of a PH-neutral detergent like Synthrapol, which is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Campeche Blue will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.