Goldenrod Extract

A Guide to Goldenrod Extract

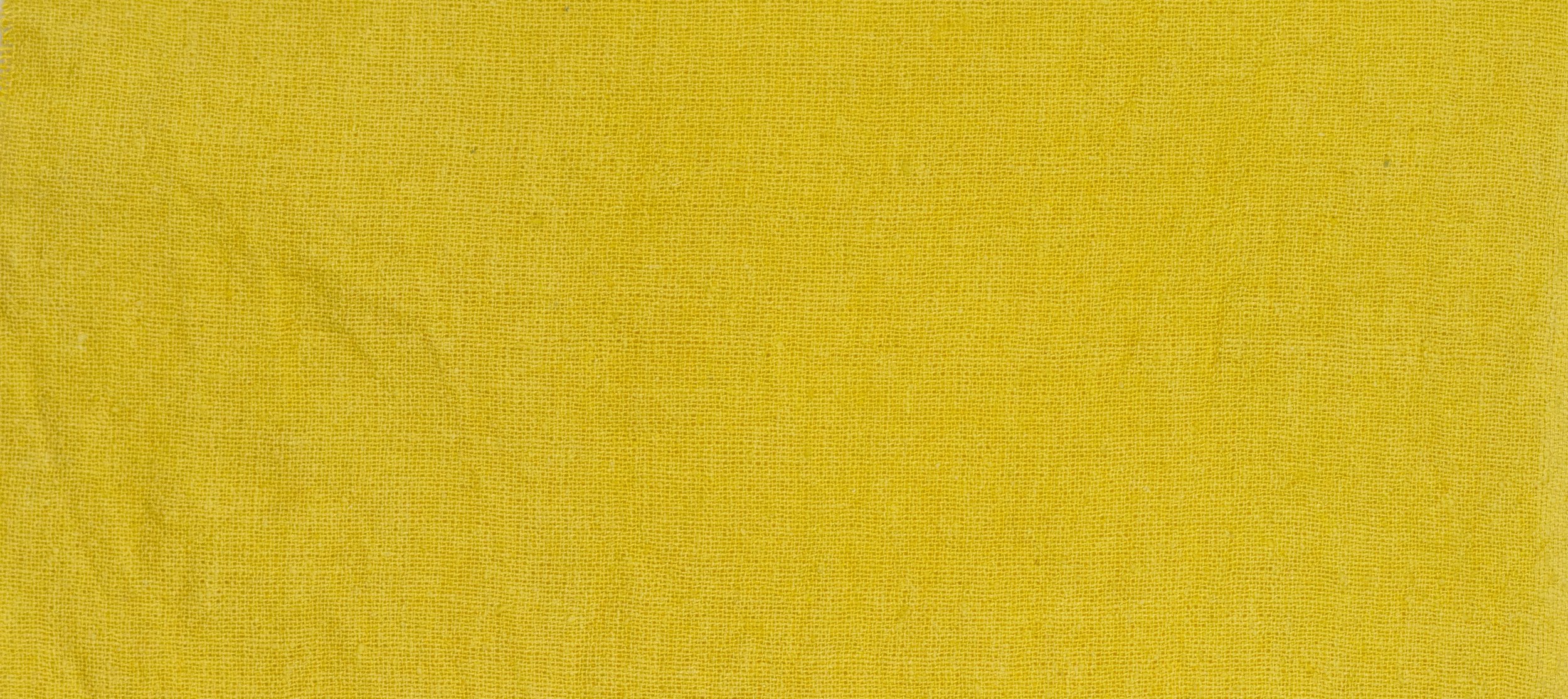

Shepherd Textiles Goldenrod Extract is produced from solidago canadensis and solidago virgaurea, the Canadian and European species of goldenrod. The plants’ tiny florets contain several pigments including quercetin, lutin, and kaempferol, which together produce cool yellows on natural fibers. Goldenrod Extract also has an affinity for iron mordants, which will shift the color to yummy sage and olive greens. Use at 25% weight-of-fabric for medium yellows or deep olives. Product of France.

1. Background on Goldenrod

Goldenrods are a widely distributed group of flowering plants belonging to the genus solidago. The most common are the European goldenrod solidago virgaurea and the Canadian goldenrod solidago canadensis. In the Pacific Northwest the local variety is solidago lepida, which blankets the lower hills of the Cascades with fields of yellow in the autumn months. Goldenrods are hardy and fast-spreading flowers, so much so that they have actually become invasive species throughout much of eastern Europe and Asia where they were initially imported as ornamentals.

Goldenrod flowers blossom in dense clusters of tiny florets, sometimes thousands on a single plant. The yellow blossoms contain a variety of flavonoid pigments including quercetin, lutin, and kaempferol. Like many yellow flowers, goldenrods can be simmered to make a dyebath and then applied to natural fibers like wool and cotton. Canadian goldenrods tend to give warmer yellows and European goldenrods softer, greener yellows. Our Goldenrod Extract is a mixture of both, and gives soft, cool yellows on mordanted fibers. Goldenrod flowers contain less concentrated pigments than some other flowers like weld or marigold, so more of the dye is required to get the same depth of shade - use 25% weight-of-fabric (WOF) of the extract for a medium yellow. Because it already produces a cool yellow tending toward the green end of the specturm, goldenrod also works well with iron mordants to create yummy sage greens.

Golden Yellow Fields

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Goldenrod Extract, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

4. Preparation: Mordanting with Alum

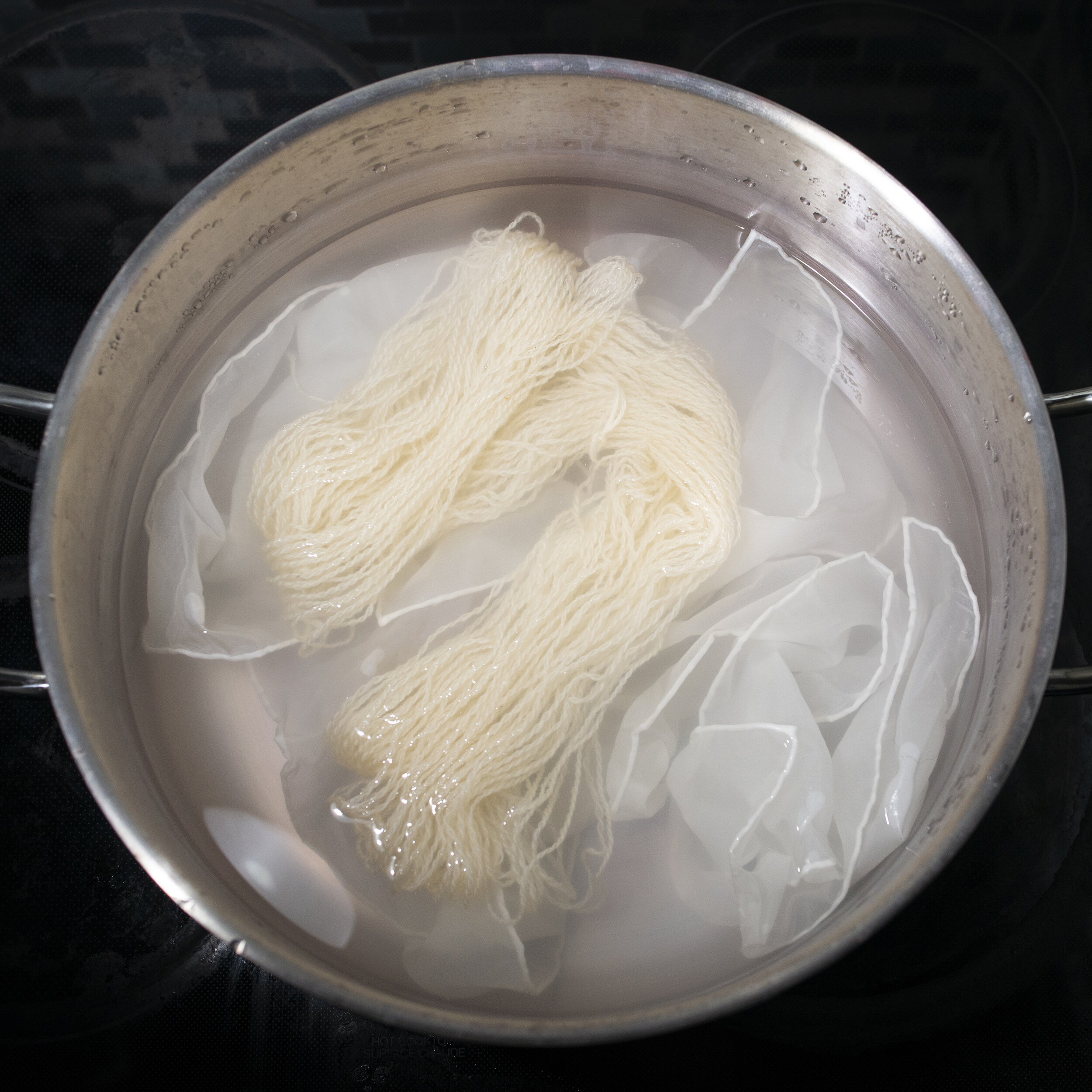

Goldenrod Extract gives the best results on fibers that have been mordanted with alum. If possible, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

For protein fibers (wool, silk, alpaca, etc.): Mordant with 10% alum and 11% cream of tartar.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.10 to calculate the amount of alum you will need, and 0.11 to calculate the amount of cream of tartar.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of cream of tartar and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Next, weight out the correct amount of alum and add it to the dye pot. Mix until well dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results when dyeing thick yarn or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers well in lukewarm water two or three times to remove excess acid and unbonded mordant. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Treat with a tannin before mordanting.

Goldenrod Extract gives pleasant lemon cream shades on cotton. For best results, the cotton should be well tanned and mordanted before dyeing.

Scour cotton by adding 2 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with hot water and dissolve 10% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they bond to the mordant. Hang the cotton up and let it dry before proceeding to mordanting.

Prepare an alum mordant bath as described above for protein fibers, but add 2% weight-of-fabric soda ash (washing soda) and mix well before adding the cotton. This will change the alum into a basic form that bonds more easily with cotton. Proceed to mordant as described above.

The Recipes

6. Recipe: Solidago Yellow

Red Sorghum Extract produces deep rusty red shades on natural fibers that have been mordanted with alum. The recipe is simple: dissolve about 5% weight-of-fabric of the extract into the dyebath, add the fibers, and simmer for an hour. For slightly deeper shades you can increase the amount of extract to 10%, but adding any more than that is not beneficial because the extra dye will not be absorbed by the fiber. This is a very natural-looking shade of red that would look nice together with other plant-based colors.

Fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 25% weight-of-fabric (WOF) of Goldenrod Extract powder. Put it in a disposable cup, add a little water, and mix well to make a slurry (if you add the powder directly to the dye pot it will clump up and be hard to dissolve). Add this slurry to the dye pot and mix well.

Add your alum-mordanted fiber to the dyebath.

Raise the temperature to 180°F for silk or 190-200°F for wool and cotton, then maintain for 1 hour. Stir occasionally to make sure everything dyes evenly.

After 1 hour, remove pot from heat and allow to cool until the fiber can safely be handled.

Remove the fibers and rinse briefly in warm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Goldenrod Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

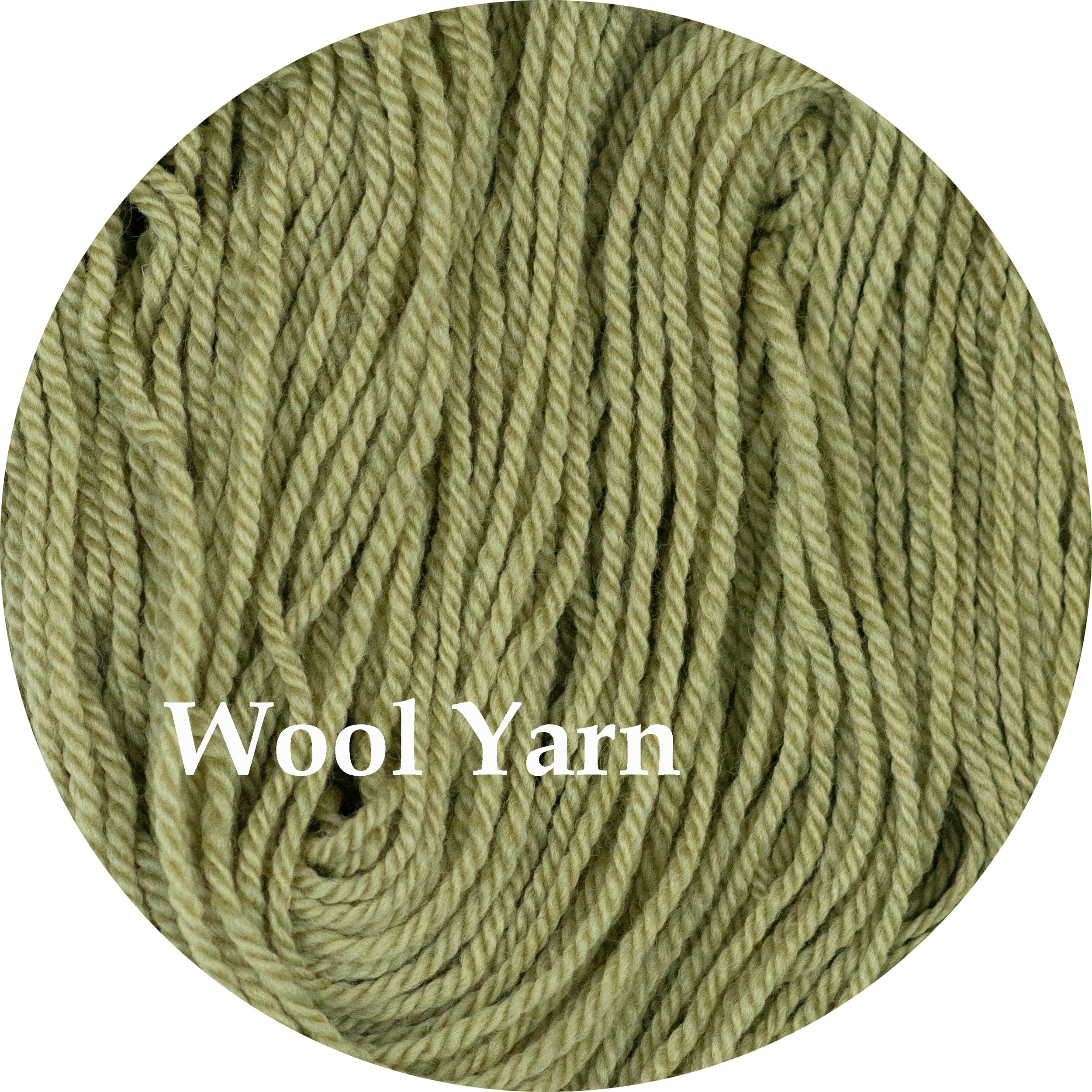

7. Recipe: Olive Green

Iron is often used to “sadden” other colors - to make them darker. After dyeing yellow with Goldenrod Extract, fibers can be simmered briefly in an iron mordant bath to shift the color from yellow to olive green. You can do this immediately after dyeing yellow, or you can do it later after the fibers have been rinsed and dried. However, be sure to wet the fibers out again before saddening them - you want the iron mordant to penetrate quickly and evenly.

Fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 4% weight-of-fabric (WOF) of iron powder (ferrous sulfate) and add to the dye pot. Mix well until fully dissolved.

Add your fibers (already dyed yellow from the recipe in Section 6) to the dye pot.

Raise the temperature to 180°F for silk or 190-200°F for wool and cotton. It will take about 5 or 10 minutes for the color to shift to green, although tightly woven fabrics or tightly spun yarn may take a little longer.

As soon as the color has shifted to green, remove the fibers from the dye bath using tongs. Transfer to a rinsing bath that is the same temperature as the iron bath (this will prevent thermal shocks on protein fibers, but is not quite so important with cotton).

Rinse the fibers well. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Goldenrod Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*CAUTION: Ferrous sulfate (iron powder) is harmful if ingested. Keep iron and iron mordant baths away from children and pets. Avoid contact with skin and mucus membranes. Wear gloves and eye protection while handling iron powder and iron mordant baths. Dispose of the spent mordant bath according to local regulations. Read your manufacturer’s SDS (Safety Data Sheet) before working with ferrous sulfate and observe all recommended safety precautions.

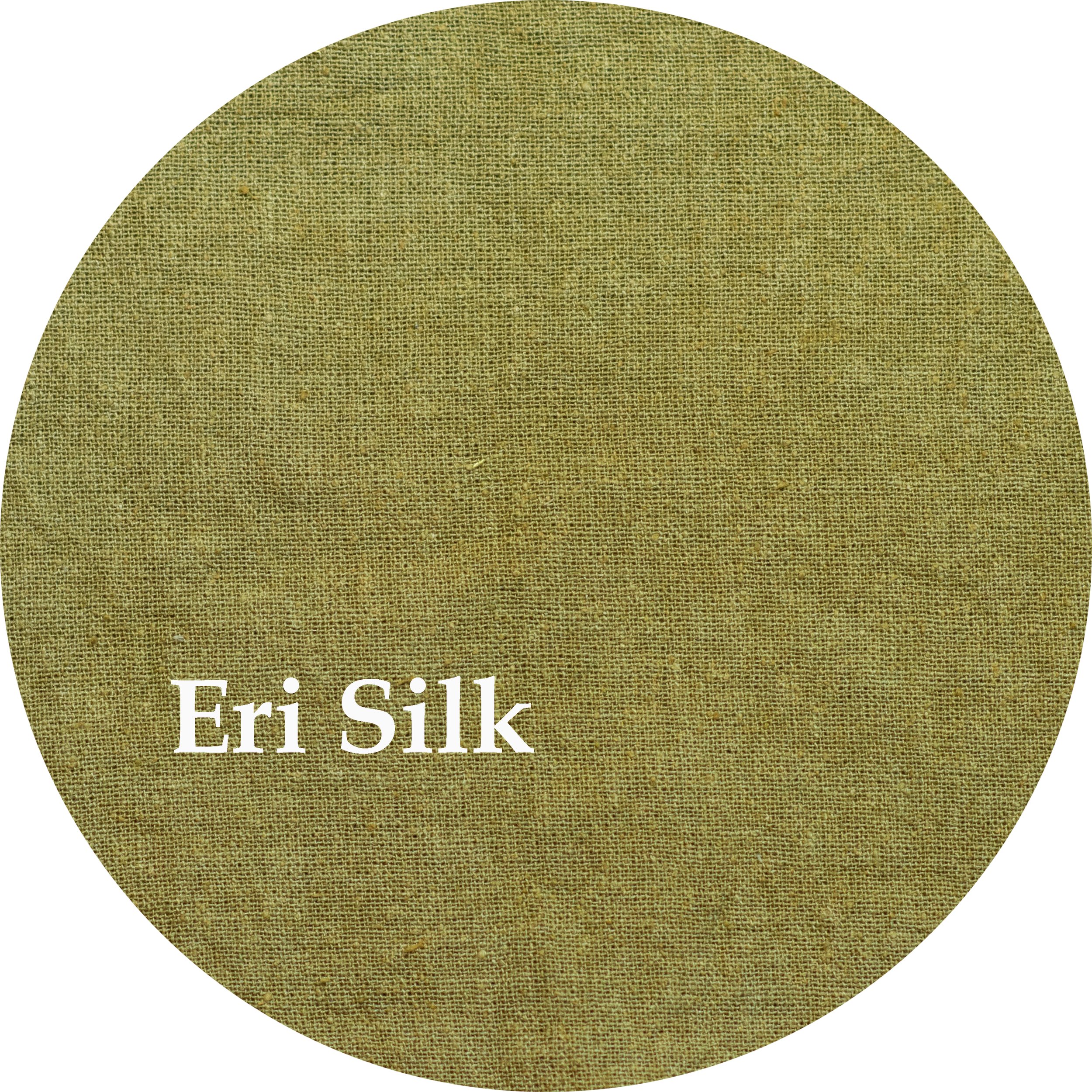

8. Recipe: Sage Green

Wool mordanted with iron will produce pleasing sage greens when dyed with Goldenrod Extract. We prefer to mordant wool with iron directly, rather than apply it as a post-mordant, because it often produces colors that are clearer and faster. Iron has a bad reputation for coarsening wool, but so long as it applied with the correct ratio of cream of tartar it will not damage the handle (softness) of the fiber.

Prepare your wool by mordanting it directly with iron. Follow the directions in Section 4, but instead of alum use 8% iron (ferrous sulfate powder) and 10% cream of tartar. Add the cream of tartar first and give it a few minutes to fully dissolve, then add the iron and give it a few minutes to fully dissolve before adding the wool. This will prevent the iron from precipitating prematurely on the wool and staining it brown*.

When finished mordanting and ready to proceed, fill your dye pot with enough warm water for your fibers to move around freely.

Measure out 10% weight-of-fabric (for a pale sage green) or 25% weight-of-fabric (for a darker moss green) of Goldenrod Extract powder. Put it in a disposable cup, add a little water, and mix well to make a slurry (if you add the powder directly to the dye pot it will clump up and be hard to dissolve). Add this slurry to the dye pot and mix well.

Add your iron-mordanted wool to the dyebath.

Raise the temperature to 190-200°F, then maintain for 1 hour. Stir occasionally to make sure everything dyes evenly.

After 1 hour, remove pot from heat and allow to cool until the wool can be safely handled.

Remove the fibers and rinse briefly in warm water. Hang them up to dry to help the color set; make sure to hang them up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For the final rinsing, we recommend using a PH-neutral detergent like Synthrapol that is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Goldenrod Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry.

*CAUTION: Ferrous sulfate (iron powder) is harmful if ingested. Keep iron and iron mordant baths away from children and pets. Avoid contact with skin and mucus membranes. Wear gloves and eye protection while handling iron powder and iron mordant baths. Dispose of the spent mordant bath according to local regulations. Read your manufacturer’s SDS (Safety Data Sheet) before working with ferrous sulfate and observe all recommended safety precautions.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.