Image 1 of 9

Image 1 of 9

Image 2 of 9

Image 2 of 9

Image 3 of 9

Image 3 of 9

Image 4 of 9

Image 4 of 9

Image 5 of 9

Image 5 of 9

Image 6 of 9

Image 6 of 9

Image 7 of 9

Image 7 of 9

Image 8 of 9

Image 8 of 9

Image 9 of 9

Image 9 of 9

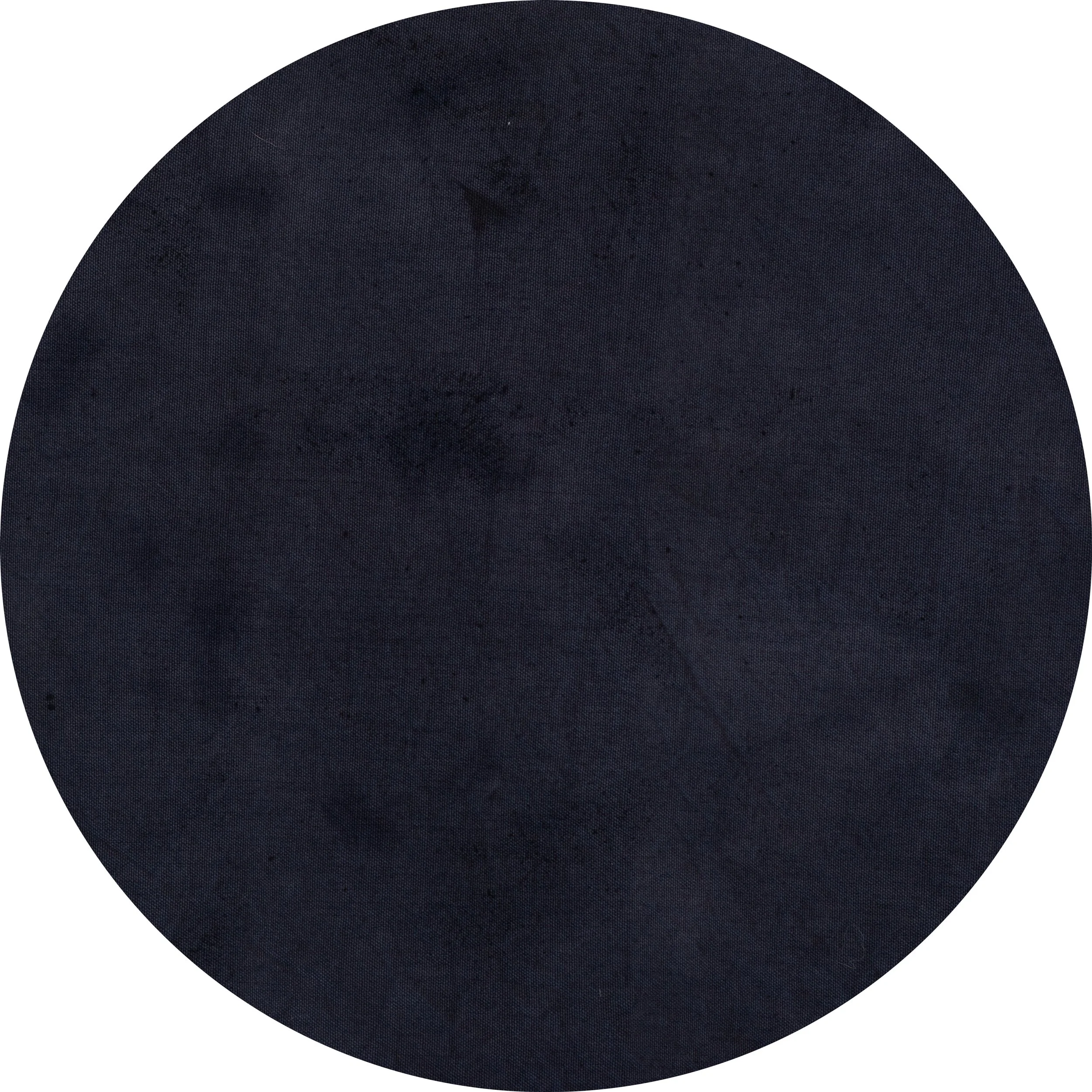

Kakishibu

Shepherd Textiles Kakishibu Natural Dye is made from the juice of the unripe Japanese persimmon (diospyros kaki). The pressed juice is aged for up to three years, during which time the persimmon tannins develop into a unique dyestuff that behaves almost like a natural polymer. Instead of bonding to fibers in a hot dye bath, kakishibu tannins bond to each other and form a coating around the fibers. Kakishibu is applied at room temperature, by dipping and drying repeatedly to build up the coating of tannins. Initially fibers dyed with kakishibu will develop an orangeish beige color, but they will darken significantly with exposure to the sun. With a few weeks of direct sunlight, the color can deepen toward a warm brown.

Kakishibu is not applied by weight-of-fabric. Instead, the important variable is the concentration of the solution. For a light solution, suitable for dyeing cotton cloth, use 1 oz. of kakishibu per 1 liter of water. For a heavy solution suitable for dyeing thin silks (or dyeing cotton to a dark shade), dissolve 3.5 oz. of kakishibu per liter of water. Mix the powder with warm water, break up any big clumps, and allow to sit for 4 hours before using - it will become slightly syrupy. Dip well-scoured, wetted fabric in the kakishibu for 20 minutes, then hang up to dry. Repeat until the desired shade is achieved, or until the kakishibu has all been soaked up. For more details, check out our Guide to Dyeing with Kakishibu (coming soon).

Product of Japan. One ounce (dissolved in 1 liter of water) is enough to dye a cotton t-shirt to a medium shade, about 3 dips. Swatches shown using a light solution (1 oz./liter).

Shepherd Textiles Kakishibu Natural Dye is made from the juice of the unripe Japanese persimmon (diospyros kaki). The pressed juice is aged for up to three years, during which time the persimmon tannins develop into a unique dyestuff that behaves almost like a natural polymer. Instead of bonding to fibers in a hot dye bath, kakishibu tannins bond to each other and form a coating around the fibers. Kakishibu is applied at room temperature, by dipping and drying repeatedly to build up the coating of tannins. Initially fibers dyed with kakishibu will develop an orangeish beige color, but they will darken significantly with exposure to the sun. With a few weeks of direct sunlight, the color can deepen toward a warm brown.

Kakishibu is not applied by weight-of-fabric. Instead, the important variable is the concentration of the solution. For a light solution, suitable for dyeing cotton cloth, use 1 oz. of kakishibu per 1 liter of water. For a heavy solution suitable for dyeing thin silks (or dyeing cotton to a dark shade), dissolve 3.5 oz. of kakishibu per liter of water. Mix the powder with warm water, break up any big clumps, and allow to sit for 4 hours before using - it will become slightly syrupy. Dip well-scoured, wetted fabric in the kakishibu for 20 minutes, then hang up to dry. Repeat until the desired shade is achieved, or until the kakishibu has all been soaked up. For more details, check out our Guide to Dyeing with Kakishibu (coming soon).

Product of Japan. One ounce (dissolved in 1 liter of water) is enough to dye a cotton t-shirt to a medium shade, about 3 dips. Swatches shown using a light solution (1 oz./liter).