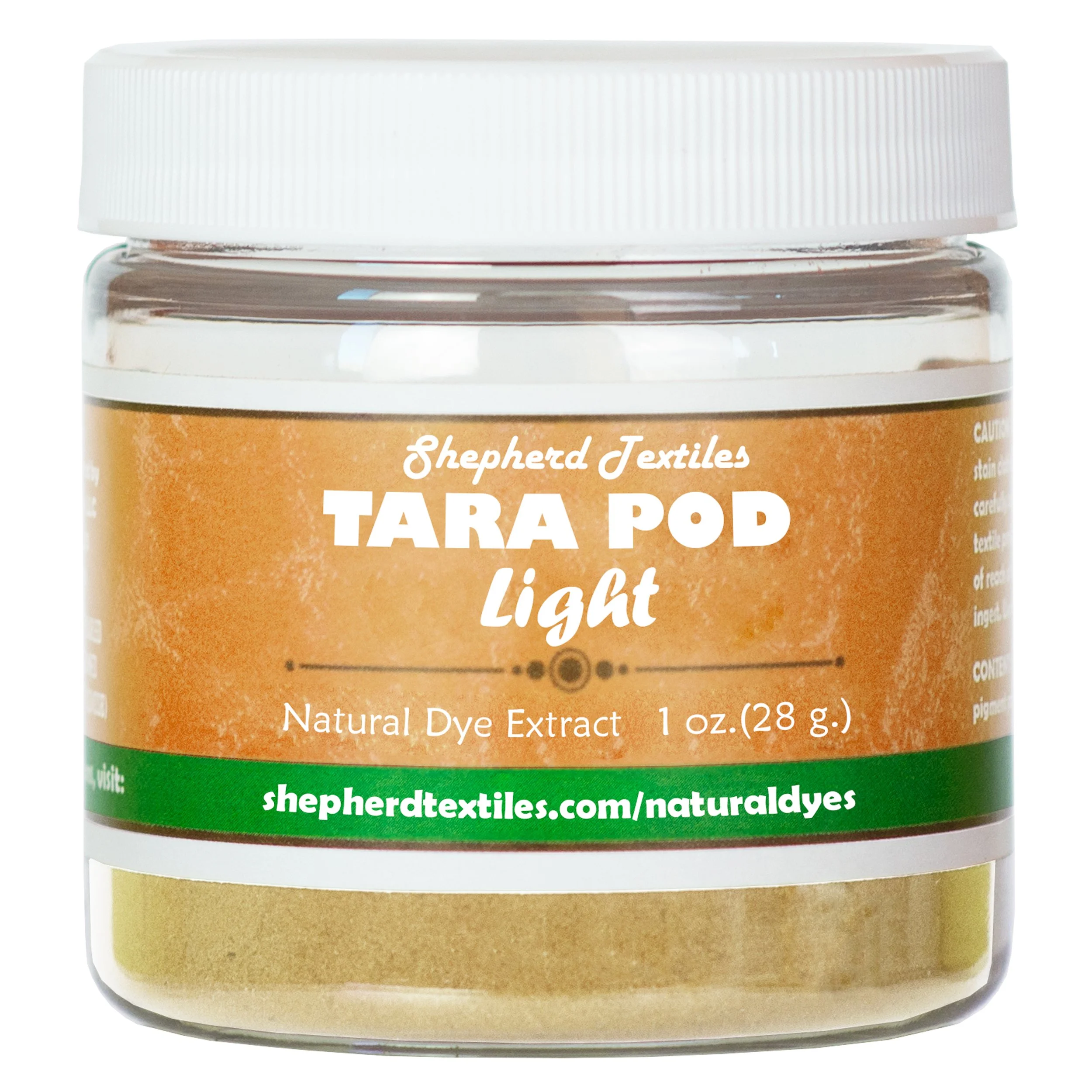

Tara Pod Light

Tara Pod Light Extract

For bright colors on cotton and linen

Tara Pod Light Extract is made from the seed pods of tara spinosa, a small leguminous tree native to the Andean regions of South America. Tara is one of the richest botanical sources of hydrolyzable tannins and it has been used for centuries for tanning leather, making ink, and preparing cotton for mordanting and dyeing. Tara Pod Light Extract is a highly concentrated and refined tara extract produced from Peruvian tara pods. It is a rich source of clear gallic tannins and it makes an excellent base for mordanting cotton and linen with aluminum and then dyeing yellows, purples, crimsons, and other bright, clear shades. Use at 10% weight-of-fabric to prepare cotton or linen fibers before mordanting with Aluminum Acetate, Aluminum Lactate, or Aluminum Formate Pro.

1. Background on Tara

Tara tannins are derived from the seed pods of tara spinosa, a small leguminous tree native to the Andean regions of Peru, Bolivia, and Ecuador. Unlike galls, which are pathological plant growths triggered by an insect sting, tara pods are normal botanical seed pods that naturally accumulate a high concentration of hydrolyzable (gallic) tannins. For centuries, Indigenous Andean cultures harvested tara for leather tanning, ink making, and textile work, taking advantage of its unusually clean, clear, and consistent tannin profile. Today, tara is valued by dyers as one of the most reliable and clear plant-based tannin sources available.

In contemporary natural dyeing, tara tannins are used primarily to prepare plant fibers such as cotton, linen, hemp, and ramie for mordanting. Cellulosic fibers have little inherent affinity for metal salts like aluminum or iron, but they will readily absorb large quantities of soluble tannins. Once the fiber has been fully saturated—a process often referred to as tanning or engallage—the tannins themselves provide the binding sites needed for mordants like aluminum and iron to attach to. Afterwards the plant fibers can be dyed in a wide range of shades using any suitable mordant dye, and the colors will have improved depth and washfastness.

Tara Pod Light Extract is a high-quality tara tannin extract specifically intended for textile dyeing. Our tara tannin is a refined, light-colored extract produced from Peruvian tara pods and contains predominantly gallic-type hydrolyzable tannins. Tara Pod Light Extract sits somewhere between Sumac Extract (which gives the brightest but lightest colors) and Oak Gall Light Extract (which gives the deepest but most opaque colors). It is a good choice for dyers looking for a tannin that balances brightness with depth. When applied to cotton or linen, it imparts little to no visible color, making it an ideal base for mordanting with aluminum and dyeing bright yellows, reds, and purples. Use at approximately 10% weight-of-fabric to prepare plant fibers for mordanting.

2. Safety Precautions

This product is intended for textile projects only. Do not ingest or apply directly to skin or hair.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Do not eat, drink, or smoke while handling this product. Wash hands after use.

Open carefully to avoid spills. If a spill occurs, quickly wipe up with a paper towel or rag.

Tara Pod Light Extract can permanently dye clothing, countertops, rugs, utensils, or other property, especially in combination with iron. Avoid contact with anything that is not meant to be dyed.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Tara Pod Light Extract, metal mordants, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely. A stainless steel stock pot usually works well.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it is rinsed.

Aluminum Formate Pro. An aluminum mordant that works especially well with plant fibers like cotton and linen.

Candy thermometer. A cheap candy thermometer that clips to the side of the dye pot will make it easier to track the temperature.

Iron mordant. The form of iron used as a mordant with Tara Pod Light Extract is ferrous sulfate (sometimes labeled ferrous sulfate heptahydrate).

Tea bags or a coffee filter. For straining the dye bath.

Scale. Use a scale to weigh out fiber, mordant, and Tara Pod Light Extract.

Recipes

4. Aluminum Colors on Cotton/Linen

Tara Pod Light Extract contains very clear tannins that on their own will leave only the faintest hint of an ivory shade on cotton and linen fibers. It has very little use as a dye itself, but it makes an excellent base for tanning plant fibers so that they can be mordanted Since it has very little color of its own, Tara Pod Light is a great choice for preparing cotton and linen for dyeing bright colors like yellow, orange, purple, and red using an aluminum mordant like Aluminum Acetate, Aluminum Lactate, or Aluminum Formate Pro. It is a good choice for dyers looking for a tannin that balances both brightness and depth.

Cotton shirt, 10% Tara Pod Light

10% Tara Pod Light + 3% French Weld Extract

10% Tara Pod Light + 40% Madder Root

Scour (clean) the cotton or linen fibers well: Fill a dye pot with enough warm water for the fibers to move around freely. Add 1 gram of soda ash (sodium carbonate), plus 1 gram for each additional pound of fiber. Add the fibers and raise the heat to a very gentle simmer. Simmer the fibers for one hour, stirring occasionally. After an hour, remove from the heat. When cool enough to handle safely, rinse well with warm water until the water runs clear.

Fill a dye pot with enough warm water for your fibers to move around freely. Weigh out 10% weight-of-fabric (WOF) of Tara Pod Light Extract, add to the water, and mix well until completely dissolved. Tara tannins can be a bit clumpy, but they will dissolve with enough stirring. If necessary, gently heating the pot will help them dissolve faster.

Gently add the cotton or linen. Bring the tannin bath just to a boil, then immediately remove the pot from the heat, cover it, and let the fibers steep until completely cool. For best results, let them steep overnight. Stir the fibers occasionally so that they absorb the tannin evenly. If you are steeping the fibers overnight, before going to bed make sure that there are no bubbles trapped underneath the fibers and that the fibers are fully submerged.

When ready to proceed, lift the fibers out of the tannin bath and gently squeeze excess liquid out (just enough so that they are not dripping). Do not rinse them. The tannin bath may be reused so long as it is not cloudy, although it may need to be topped off with more Tara Pod Light extract.

Fill a dye pot or plastic bucket with enough soft or distilled water for the fibers to move around freely. The water should be room temperature or slightly lukewarm, around 80-90°F (27-32°C).

Weigh out 10% weight-of-fabric (WOF) of Aluminum Formate Pro. Add to the mordant bath and mix well until fully dissolved. The mordant bath will turn a milky white color [see Note 1].

Gently add your tara pod-treated cotton or linen fibers to the mordant bath. Wearing rubber gloves, work the fibers in the liquid to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath.

Cover the pot or bucket and let the fibers steep for 2 hours. Stir the fibers a few times while they are steeping to make sure they mordant evenly. After 2 hours, the cotton or linen will be thoroughly mordanted with aluminum.

[Optional] This step is optional but recommended. Prepare a chalk fixing bath: fill a bucket or dye pot with hot tap water (around 110°F/43°C). Measure out 2 grams of chalk (calcium carbonate) per liter of water. Add the chalk and mix well until dispersed. Wearing gloves, remove the cotton or linen from the mordant bath, gently squeeze out, then place it in the chalk fixing bath. Let the fibers steep in the fixing bath for 10 minutes [see NOTE 2]. After ten minutes most of the excess mordant will be precipitated out of the fibers and the fibers can be removed and rinsed.

Rinse the fibers. Wearing gloves, remove the cotton or linen from the mordant bath or fixing bath (if used) and rinse well until the water runs clear. It is important to rinse out excess mordant and tannin at this stage, because otherwise it will cause trouble later on in the dye bath (some of the excess mordant may bleed out into the dye bath and waste dye, and some of it may fix superficially to the surface of the fibers and make them tedious to rinse).

When the cotton or linen has been thoroughly rinsed, proceed directly to dyeing. The swatches above show cotton tshirts mordanted with Tara Pod Light and Aluminum Formate Pro, then dyed with French Weld Extract and Madder Root.

NOTE 1. Other aluminum mordants for plant fibers, like Aluminum Acetate or Aluminum Lactate, could be applied instead. See each product page for details.

NOTE 2. The chalk fixing bath helps to precipitate any extra mordant that is not completly fixed by the tara tannins. This will help prevent bleeding and make rinsing the fibers easier after dyeing.

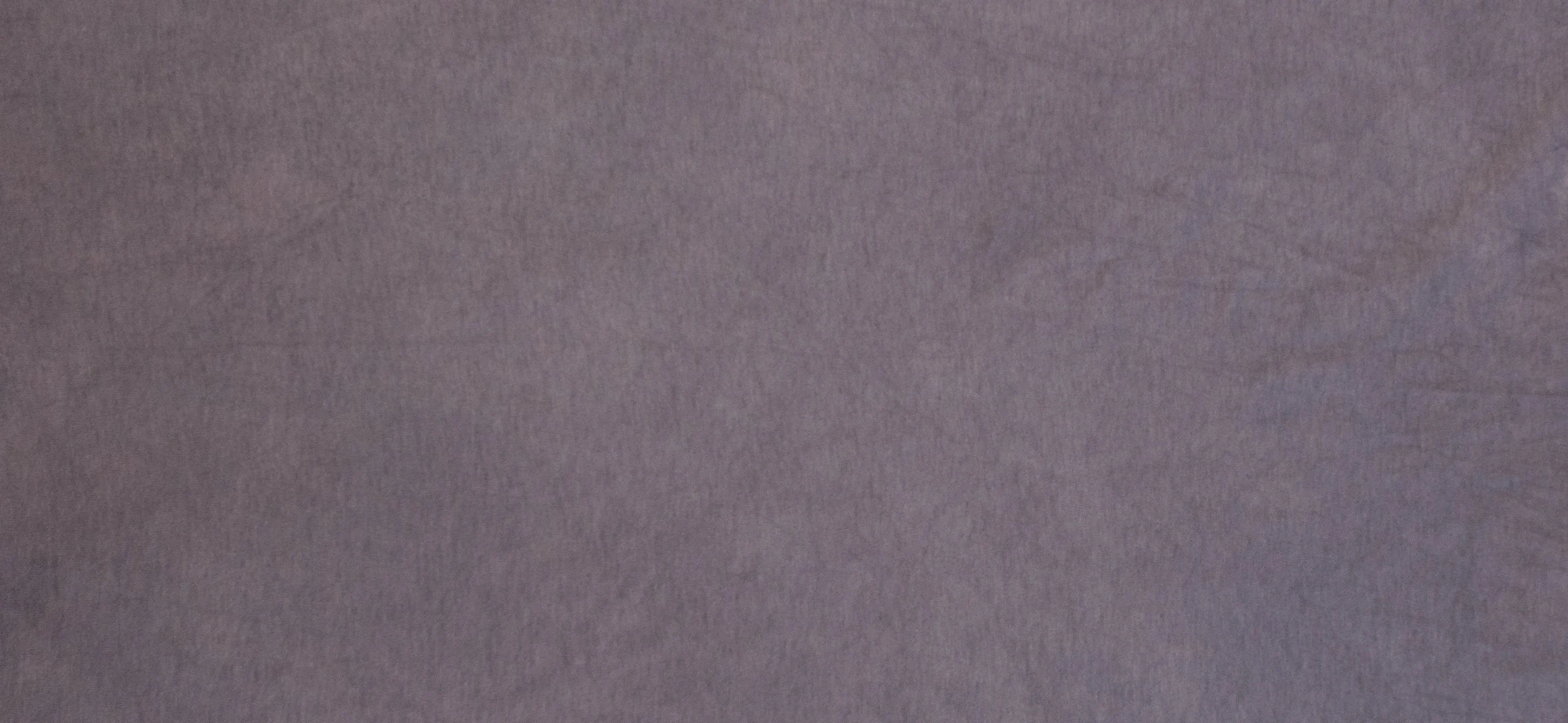

5. Iron Purple on Cotton/Linen

Tara is unique among all the major textile tannins (sumac, oak gall, pomegranate, etc.) in that when it is combined with iron, the resulting color complex is unstable. In soft or distilled water, tara and iron will produce a beautiful blueish gray shade on cotton or linen. However, if the fibers are introduced to hard or alkaline water, the color quickly transforms to purple-brown (the other major tannins are not unstable in this way and can tolerate hard or alkaline conditions without a color shift). If you have hard water, this can be a method for getting a purple on cotton without having to use any other dyes. However, it makes a poor base for dyeing other colors. Unless you are specifically seeking this purple shade, we recommend using other tannins like Sumac Extract or Oak Gall Extract for dyeing with iron, and saving Tara Pod Light Extract for use with aluminum mordants.

10% Tara Pod Light + 5% Iron

Scour (clean) the cotton or linen fibers well: Fill a dye pot with enough warm water for the fibers to move around freely. Add 1 gram of soda ash (sodium carbonate), plus 1 gram for each additional pound of fiber. Add the fibers and raise the heat to a very gentle simmer. Simmer the fibers for one hour, stirring occasionally. After an hour, remove from the heat. When cool enough to handle safely, rinse well with warm water until the water runs clear.

Fill a dye pot with enough warm water for your fibers to move around freely. Weigh out 10% weight-of-fabric (WOF) of Tara Pod Light Extract, add to the water, and mix well until completely dissolved. Tara tannins can be a bit clumpy, but they will dissolve with enough stirring. If necessary, gently heating the pot will help them dissolve faster.

Gently add the cotton or linen. Bring the tannin bath just to a boil, then immediately remove the pot from the heat, cover it, and let the fibers steep until completely cool. For best results, let them steep overnight. Stir the fibers occasionally so that they absorb the tannin evenly. If you are steeping the fibers overnight, before going to bed make sure that there are no bubbles trapped underneath the fibers and that the fibers are fully submerged.

When ready to proceed, lift the fibers out of the tannin bath and gently squeeze excess liquid out (just enough so that they are not dripping). Do not rinse them. The tannin bath may be reused so long as it is not cloudy, although it may need to be topped off with more Tara Pod Light extract.

Fill a dye pot or plastic bucket with enough soft or distilled water for the fibers to move around freely. The water should be room temperature or slightly lukewarm, around 80-90°F (27-32°C).

Weigh out 5% weight-of-fabric (WOF) of Ferrous Sulfate powder. Add to the mordant bath and mix well until fully dissolved.

Gently add your tara pod-treated cotton or linen fibers to the mordant bath. Wearing rubber gloves, work the fibers in the liquid to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath.

Cover the pot or bucket and let the fibers steep for 2 hours. Stir the fibers a few times while they are steeping to make sure they mordant evenly. After 2 hours, the cotton or linen will be thoroughly mordanted with iron. So long as soft or distilled water was used, the fibers should be a deep bluish gray shade.

To get the purple-brown shade, the iron-mordanted fibers simply need to be steeped in hard, alkaline water [see Note 1]. Our studio is located in a region with naturally hard water, so all we have to do is rinse the fibers and the color quickly shifts. If you do not have hard water, you can approximate it. Fill a dye pot with enough lukewarm water for your fibers to move around freely and add one or two grams of chalk (calcium carbonate) per gallon of water. Mix well, then place the fibers in this mild chalk bath and let steep for ten or twenty minutes. Only a small amount of chalk is needed; if too much is used the reaction can happen too quickly and the purple will come out splotchy.

Once the color shift is complete, rinse the fibers well and hang up to dry out of direct sunlight. We do not recommend dyeing the fibers further after the shade has changed to purple-brown, because the mordanting power of the iron will be mostly spent and the fibers will not take much dye [see Note 2]. If you do want to try and dye them further (say, with logwood to get a slightly darker purple), use only a fraction of the amount of dye you would normally use.

NOTE 1. If you naturally have soft, neutral water, you do not have to force the color shift to purple and you can try using tara + iron like any other tannin with an iron mordant (for example, sumac + iron or oak gall + iron). However, since the tara tannin and iron complex is unstable, you may need to be careful that the dyed fibers are never washed or rinsed with hard water or alkaline detergents.

NOTE 2. The cause of the color shift is not entirely clear. It may be that the calcium in the hard water is forming a closed compound with the tara tannins and the iron (some sort of iron-calcium-tannate compound) that no longer has the capacity to bond to dyestuffs. Or, it may be that alkaline hard water causes the iron that is bound with the tara tannins to oxidize from its ferrous form to its ferric form. Either explanation is plausible. What is certain, however, is that once the transformation occurs, the mordanting potential of the iron is basically spent.

*All text and images are copyright of Shepherd Textiles, LLC. Do not reproduce without permission and attribution.